Tail end joint of alternating current charging gun

A tail-end joint and AC charging technology, which is applied in the direction of circuits, connections, electric vehicles, etc., can solve the problems of poor waterproof effect of waterproof joints and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

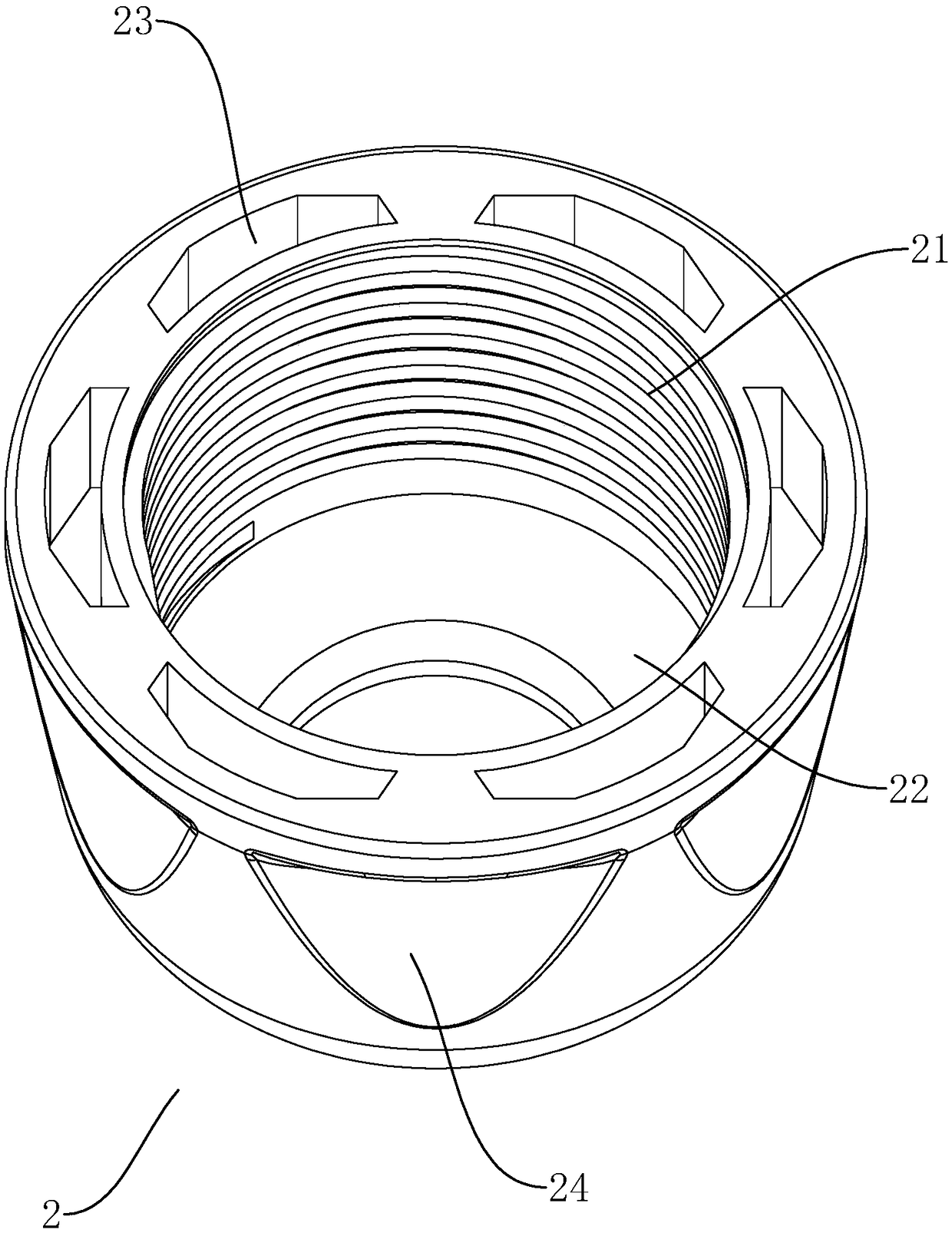

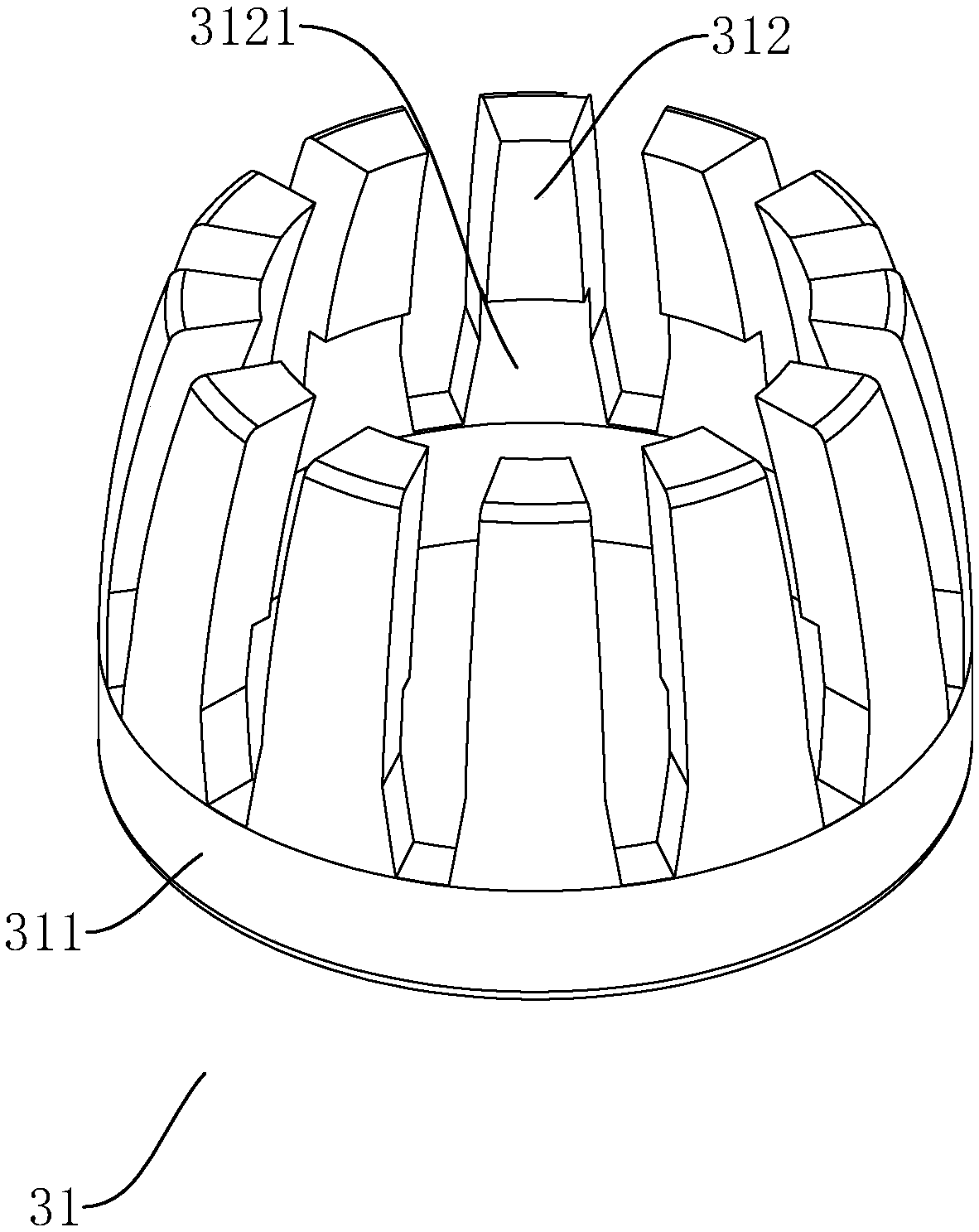

[0021] pass Figure 1 to Figure 6 The tail connector of the AC charging gun of the present invention will be further described.

[0022] A tail end connector of an AC charging gun. This embodiment is used in conjunction with the handle housing. The tail end of the handle housing 1 is formed with a connecting pipe 11 , and the tail end connector is threadedly connected to the connecting pipe 11 .

[0023] The tail joint includes an outer tube 2 and an inner tube 3. The outer tube 2 is divided into a connection section 21 and an extruded section 22 along its axial direction. The inner wall of the connection section 21 has an internal thread, and through the internal thread It is threadedly connected to the connecting pipe 11 , and the inner diameter of the extrusion section 22 is smaller than the inner diameter of the connecting section 21 . The inner tube 3 is divided into a positioning section 33 and a deformation section 34 along its axial direction, the diameter of the defo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com