Feeding device for tire wire winding machine

A technology of a steel wire winding machine and a feeding device, which is applied in the production of bead rings or bead cores, can solve the problems of unstable steel wire tension, many hidden dangers in use, affecting quality, etc. Smooth running and braking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with drawings and embodiments.

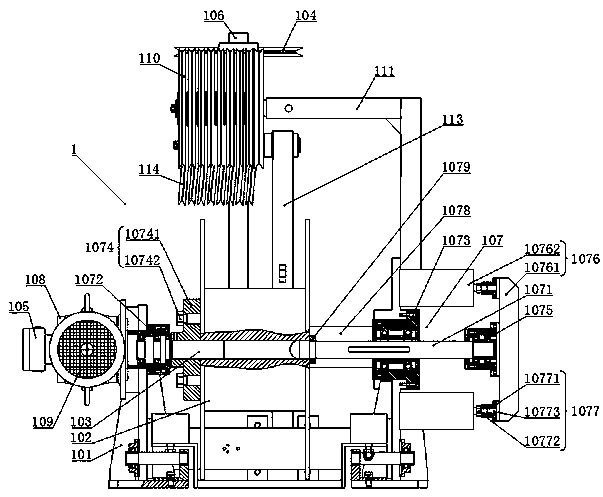

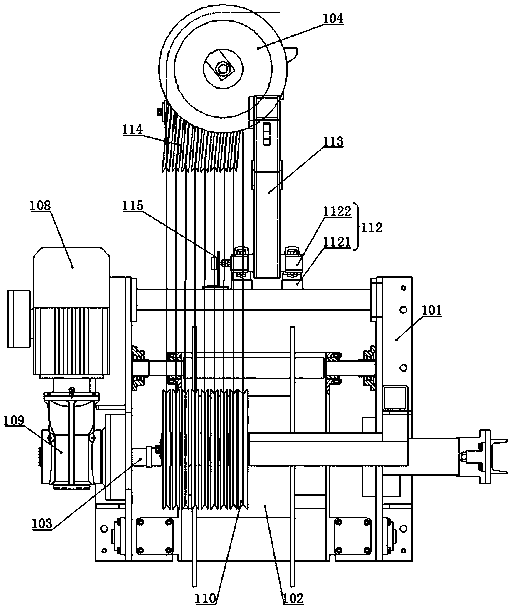

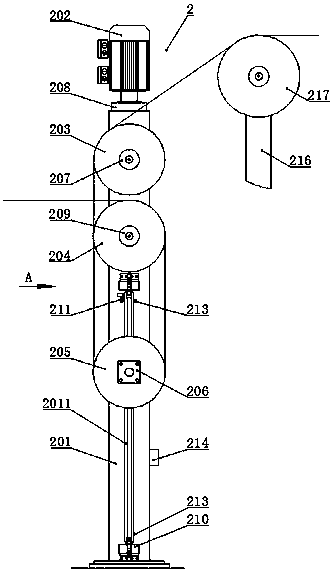

[0023] exist figure 1 Among them, a feeding device for a steel wire winding machine, which includes a guide mechanism 1, the guide mechanism 1 includes a guide bracket 101, an I-shaped wheel 102, a guide shaft 103, a guide output wheel 104 and a controller 105 . Wherein, the I-shaped wheel 102 is used to wind the steel wire raw material, which improves the convenience of transportation and storage of the steel wire raw material.

[0024] like figure 1 As shown, a support rod 106 is fixedly connected to the output end of the diversion bracket 101 , and the diversion output wheel 104 is rotatably supported on the top end of the support rod 106 .

[0025] exist figure 1 Among them, the two ends of the I-shaped wheel 102 are rotatably supported on the guide bracket 101 through the guide rotating shaft 103 and the clamping member 107 respectively. Among them, such as f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com