Aerated concrete building block cutting line

A technology of aerated concrete and cutting lines, applied in auxiliary molding equipment, ceramic molding machines, manufacturing tools, etc., can solve problems such as manual collection of corner waste, and achieve the effects of synchronization, energy saving, and manpower saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

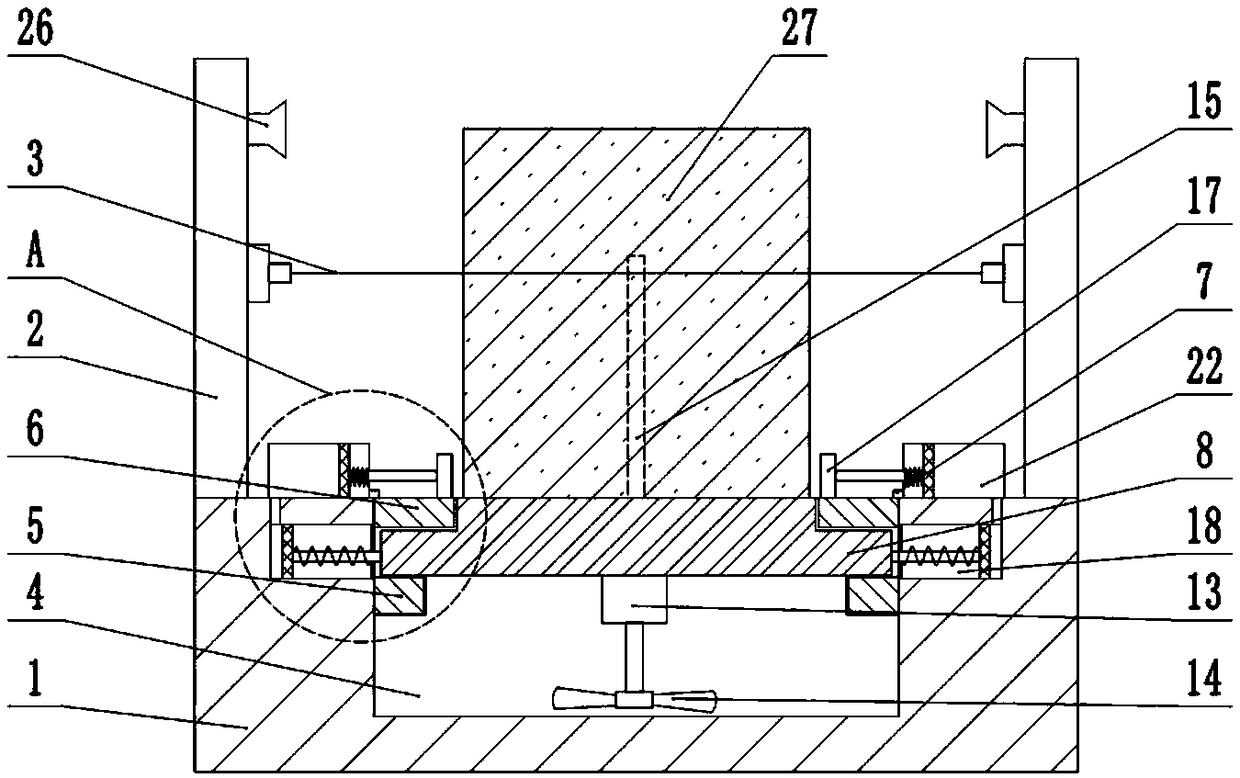

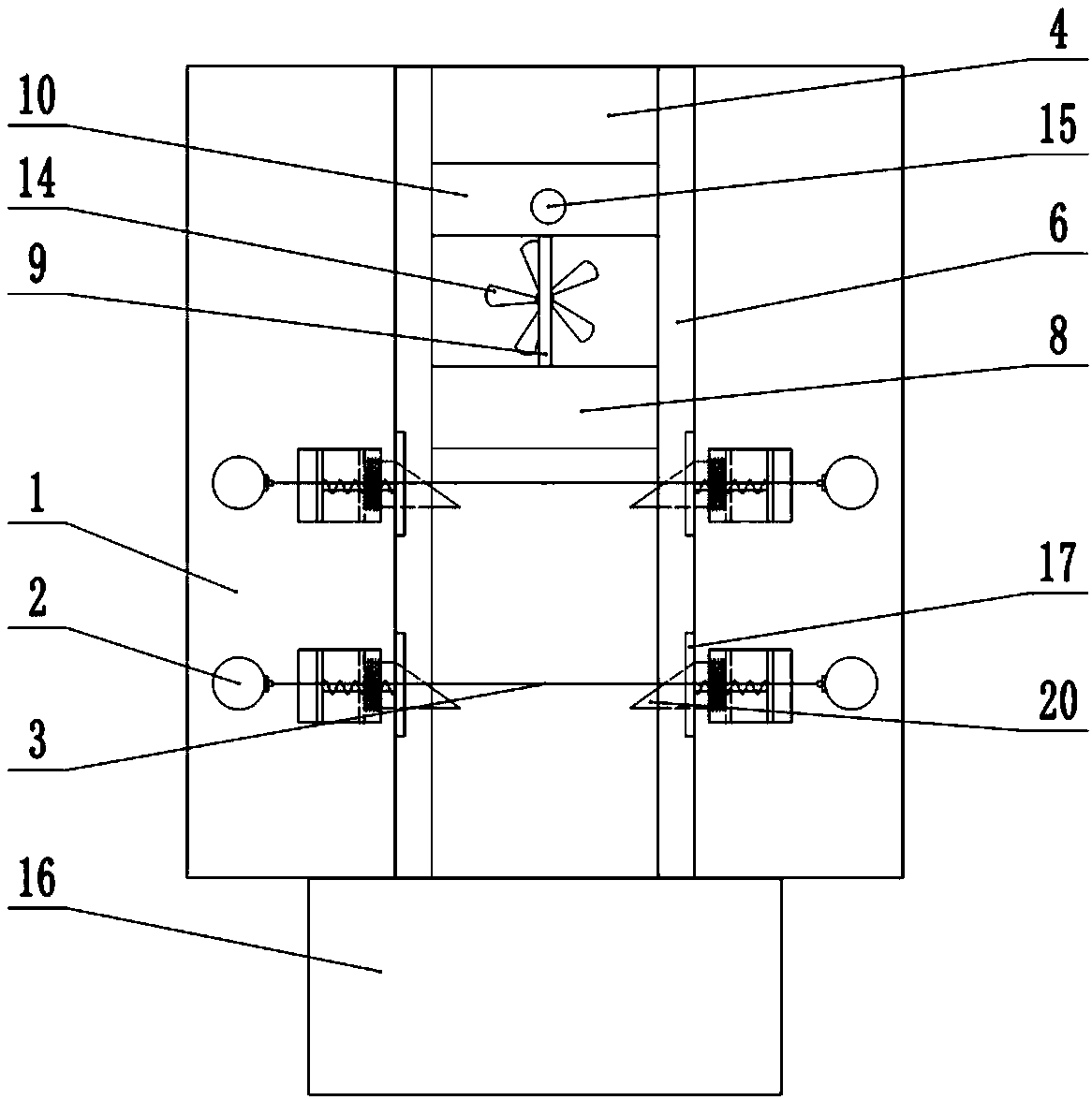

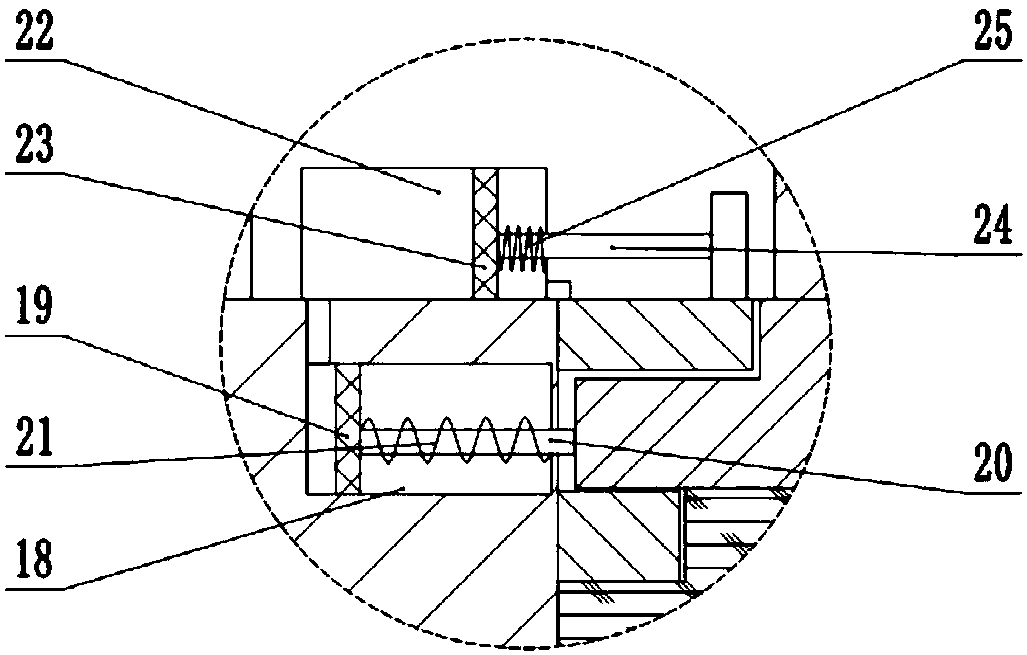

[0025] basically as figure 1 , figure 2 Shown: cutting line of aerated concrete block, including workbench 1, slide rail 5, carrying vehicle 8, support rod 2, cutting wire 3 and cleaning mechanism, support rod 2 is fixed on workbench 1 by bolts, cutting wire 3 It is fixed on the support rod 2, and the support rod 2 is fixed with a shower head 26, and the shower head 26 is connected with a water inlet pipe.

[0026] The cleaning mechanism includes a slider 10 and a cleaning plate 11. A groove 4 is provided on the workbench 1. The slide rail 5 is fixed on the side wall of the groove 4 by bolts. The upper side plate 6 is welded with a reinforcing plate 7 between the side plate 6 and the workbench 1. Carrying vehicle 8 and slide block 10 are all slidably connected between slide rail 5 and side plate 6, and carrying vehicle 8 is connected with the air cylinder that pushes carrying vehicle 8 to slide on slide rail 5; Bolt is fixed with connecting rod 9, and cleaning plate 11 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com