Thin plate part tooth profile machining tool and method thereof

A technology for connecting parts and connecting plates, which is applied in metal processing equipment, gear tooth manufacturing devices, gear teeth, etc., can solve the problems of unstable clamping and difficult processing, and achieves reduction of scrap rate, high application value, and quality assurance. The effect of machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

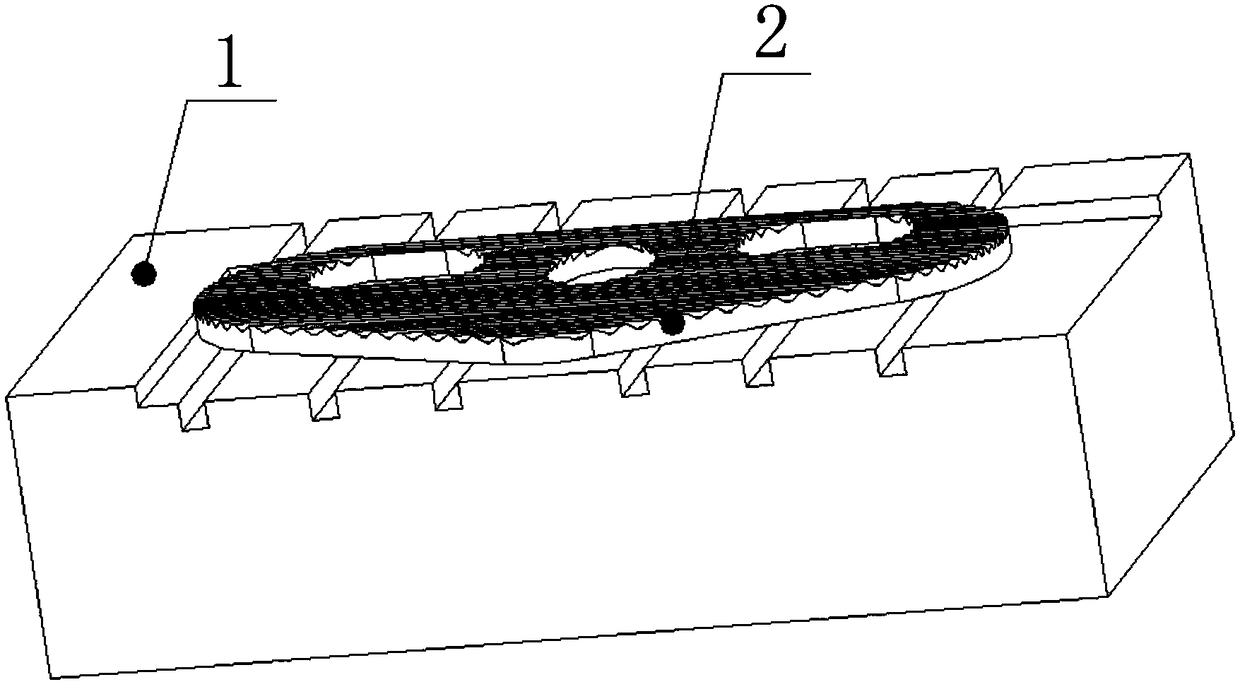

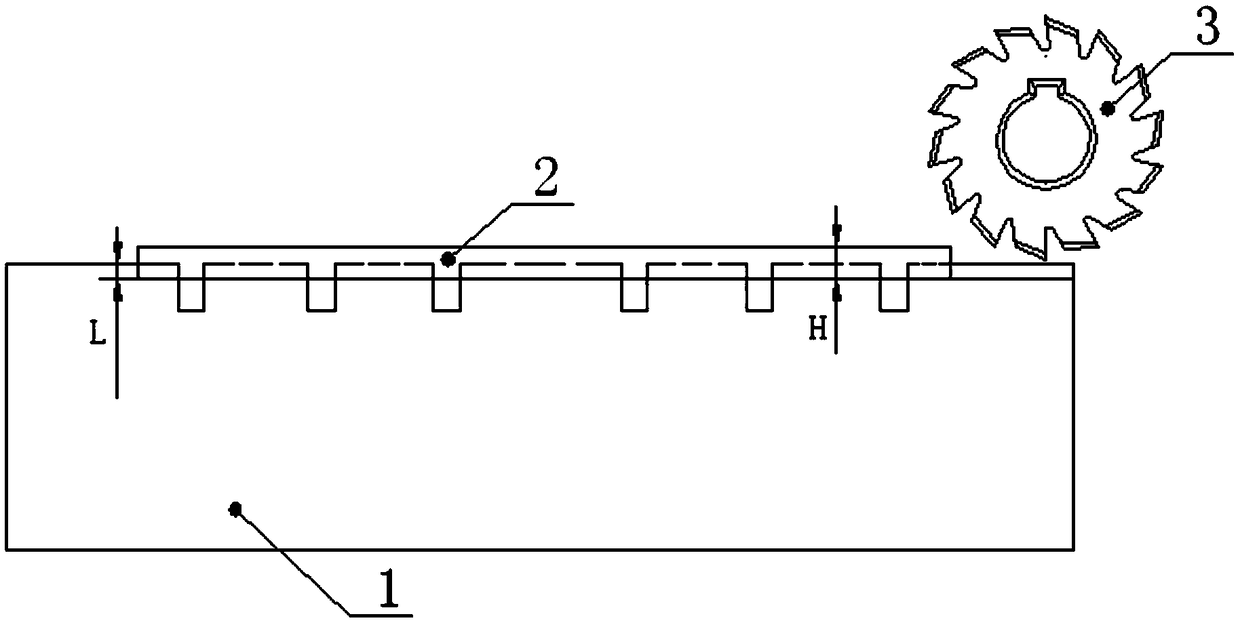

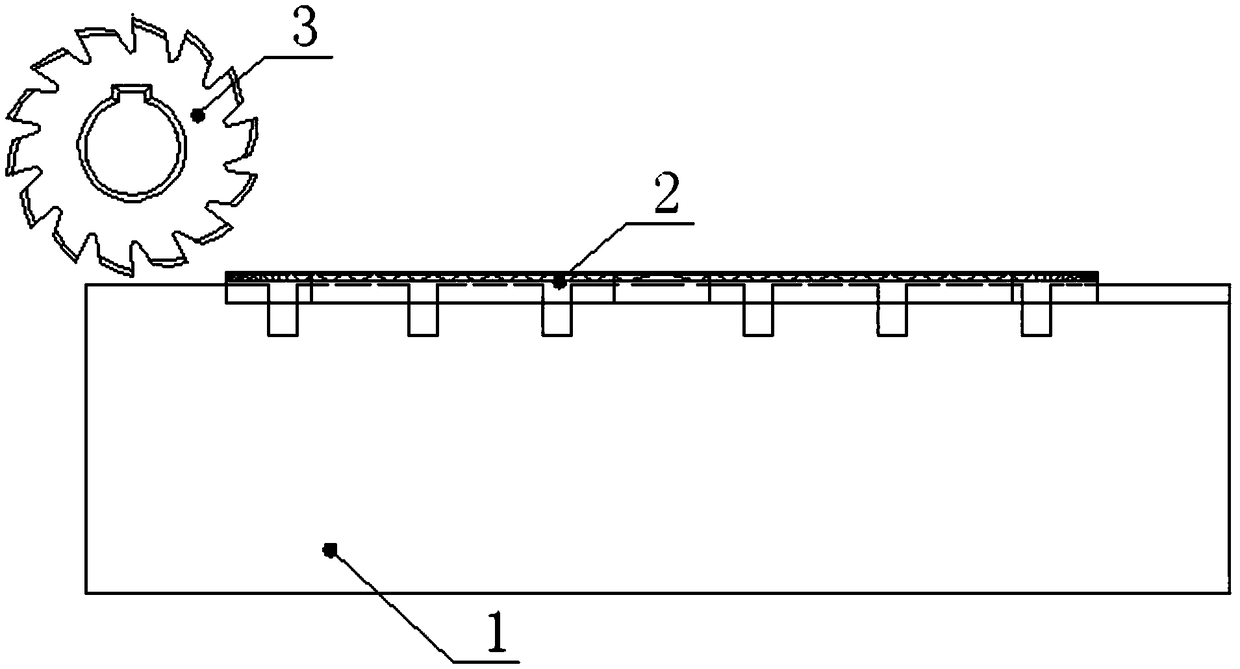

[0014] Provided is a tooth-shaped tooling for processing thin plate parts, the tooling is a structure, the lower part of which can be fixed on a processing platform, and its upper end surface is a supporting surface for carrying and fixing thin plate parts, and the upper end surface protrudes The horizontal positioning edge and the vertical positioning edge are formed, the height L of the horizontal positioning edge and the longitudinal positioning edge is 0.5-1.5 mm; the thickness H of the thin plate part is 1-3 mm; the thickness of the thin plate part is greater than that of the horizontal positioning edge Height, the thickness of the thin plate parts is greater than the height of the longitudinal positioning edge; the height of the lateral positioning edge and the longitudinal positioning edge are the same; the upper end surface has a plurality of grooves; the horizontal positioning edge and the longitudinal positioning edge are enclosed L-shaped.

[0015] A processing meth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com