Rotary garlic pressing device

A technology of a garlic press and a pressing plate, which is applied in the field of kitchen utensils, and can solve problems such as waste of garlic and decreased efficiency of the garlic press

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

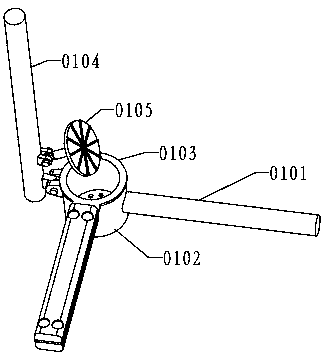

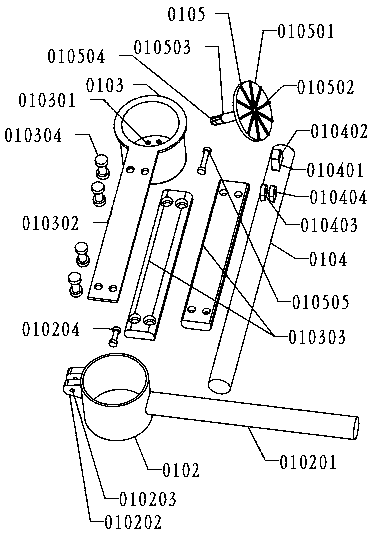

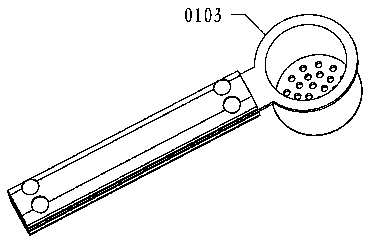

[0010] The invention provides a rotary garlic press, such as Figure 1-21 As shown, the rotary garlic press 0101 includes an upper handle 0104, a base 0102, a barrel 0103, and a pressing plate 0105. Bucket handle 010302, handle gasket 010303, bucket through hole 010301, bucket upper bottom surface 010312, handle gasket 010303 is fixed on the bucket handle 010302 by bolt 010304, the top edge of the bucket through hole 010301 is Fast mouth type, on the upper handle 0104 there are hinged blocks 010403, through holes 010404, hinged blocks 010401, through holes 010402, on the pressure plate 0105 there are ribs 010502, on the bottom surface of the pressure plate 010501, on the pressure plate column 010503, through holes 010504, and the convex ribs 010502 make the pressure plate The bottom surface 010501 of 0105 becomes a relatively passivated and uneven grinding plate structure with the upper bottom surface of the barrel 010312 and the upper edge of the through hole of the barrel 01...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com