Multifunctional automatic hairbrush

A multi-functional, automatic technology, applied in brushes, brushes, household appliances, etc., to achieve the effect of improving automation, eliminating waste, and saving time for ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

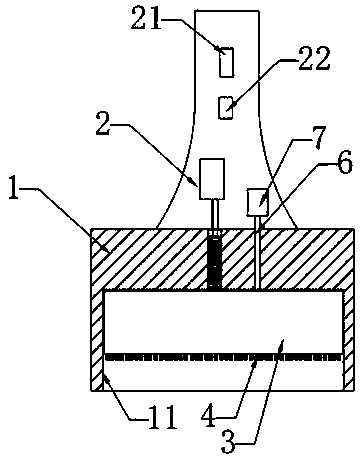

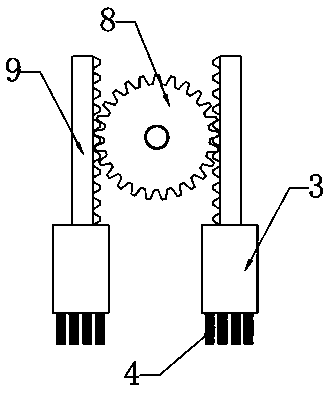

[0023] Such as figure 1 , image 3 As shown, the transmission mechanism includes a servo motor, a gear 8 fixedly connected to the output shaft of the servo motor, and a rack 9 meshing with the gear 8 is respectively arranged on the left and right sides of the gear 8, and the rack 9 is located at the brush Inside the body 1, the racks 9 are arranged vertically and parallel to the central axis in the thickness direction of the brush body 1. Each rack 9 corresponds to a slider 3, and the slider 3 is fixedly installed on the lower end of the rack 9. When the servo motor starts, it drives the gear 8 fixedly connected with it to rotate, and after the gear 8 rotates, it drives the racks 9 meshing with it on both sides to slide upwards and downwards respectively, thereby realizing the opposite movement of two adjacent sliders 3 . At the same time, when the rack 9 slides a certain distance, the servo motor controls its output shaft to reverse, so that the gear 8 will reverse according...

Embodiment 2

[0027] Above-mentioned transmission mechanism can adopt existing crank-link mechanism to replace. Specifically, the transmission mechanism includes a motor, a crank and a connecting rod. One end of the connecting rod is connected to the crank, and the other end is fixedly connected to the slider 3. The crank is connected to the motor, and the motor drives the crank to rotate. After the crank rotates, Drive the connecting rod to move, thereby driving the slider 3 to reciprocate up and down.

[0028] In addition, in order to facilitate the control of the operation of the slider 3 and the nozzle assembly, the brush handle 2 is provided with a vibration switch 21 for controlling the opening and closing of the servo motor that drives the slider 3 to slide, and a vibration switch 21 for controlling the opening and closing of the motor for the nozzle assembly to absorb paint. Injection switch 22.

Embodiment 3

[0030] Specifically, each slider 3 corresponds to a transmission mechanism, and the transmission mechanism includes an air compressor, and a plurality of airflow passages connected with the exhaust port of the air compressor are arranged in the brush body, and each airflow passage corresponds to a slider 3. A return spring corresponding to the airflow channel is fixedly installed on each slider 3 . When in use, the high-pressure gas generated by the air compressor makes the spring-mounted slider 3 move under pressure, and when it reaches a certain position, the gas pressure is released, and the slider 3 rebounds under the action of the spring to realize the up and down movement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com