Manufacture method of instant pungent and spicy beef

A production method and beef technology, applied in the functions of food ingredients, food ingredients as odor modifiers, food science and other directions, can solve the problems of limited seasoning time, no spicy, tough taste, etc., and achieve long shelf life, rich aroma, The effect of promoting absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

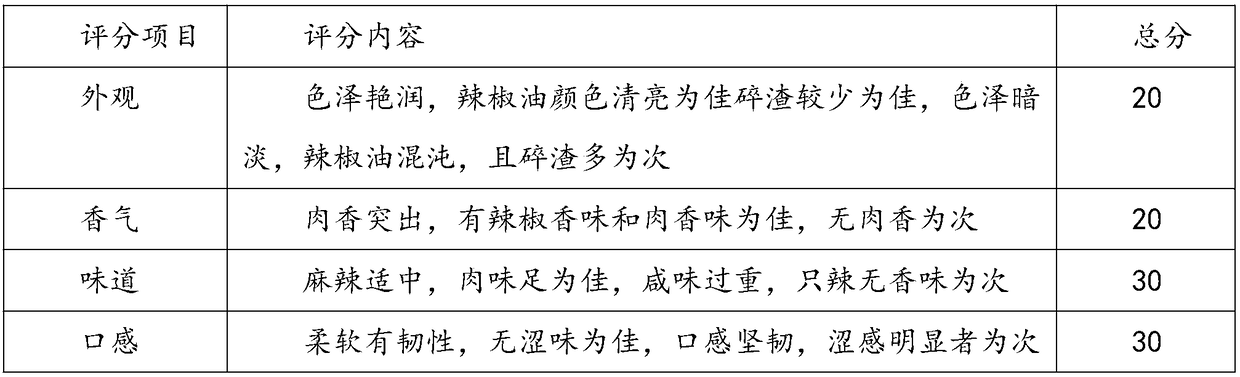

Examples

Embodiment 1

[0045] A preparation method of instant spicy beef is characterized in that it comprises the following steps:

[0046] (1) Select yellow beef from Xuanhan County, remove the fat, sarcolemma, lymph, and muscle fiber texture in the meat, cut the raw meat into pieces, soak in water for 6 hours, rinse the blood and sewage, and drain;

[0047] (2) Take 2 parts of onion, 2 parts of tomato, 2 parts of cooking wine, and 0.5 part of ginger according to the weight components, smash the tomato and onion into a pulp, knead with cooking wine, ginger and beef for 10 minutes, and then marinate. For 5 hours, every 1 hour of pickling, kneading once, a total of 5 times of kneading;

[0048](3) Take 5 parts of three Nye, 2 parts of Tsao Guo, 3 parts of Zanthoxylum bungeanum, 2 parts of clove, 1 part of licorice, 3 parts of star anise, 2 parts of Angelica dahurica, 3 parts of cinnamon, 3 parts of fennel, 4 parts of Piper dial according to the weight components, 5 parts of Xiangguo, 3 parts of Mux...

Embodiment 2

[0056] A preparation method of instant spicy beef is characterized in that it comprises the following steps:

[0057] (1) Select yellow beef from Xuanhan County, remove the fat, sarcolemma, lymph, and muscle fiber texture in the meat, cut the raw meat into pieces, soak in cold water for 6 hours, rinse the blood and sewage, and drain;

[0058] (2) Take 2.5 parts of onion, 2.5 parts of tomato, 3 parts of cooking wine, and 0.8 part of ginger according to the weight components, smash the tomato and onion into a pulp, knead with cooking wine, ginger and beef for 10 minutes, and then marinate. For 6 hours, every 1 hour of marinating, kneading once, a total of 6 kneading times;

[0059] (3) Take 5 parts of three Nye, 2 parts of Cao Guo, 4 parts of Zanthoxylum bungeanum, 2 parts of clove, 2 parts of licorice, 4 parts of star anise, 3 parts of Angelica dahurica, 3 parts of cinnamon, 3 parts of fennel, 4 parts of Piper dial according to the weight components, 5 parts of Xiangguo, 3 par...

Embodiment 3

[0067] (1) Select yellow beef from Xuanhan County, remove the fat, sarcolemma, lymph, and muscle fiber texture in the meat, cut the raw meat into pieces, soak in cold water for 6 hours, rinse the blood and sewage, and drain;

[0068] (2) Take 3 parts of onion, 3 parts of tomato, 4 parts of cooking wine, and 1 part of ginger according to the weight components, smash the tomato and onion into a slurry, knead with cooking wine, ginger and beef for 10 minutes, and then marinate. For 8 hours, every 1 hour of marinating, kneading once, a total of 8 times of kneading;

[0069] (3) Take 5 parts of three Nye, 2 parts of Tsao Guo, 5 parts of Zanthoxylum bungeanum, 2 parts of clove, 3 parts of licorice, 5 parts of star anise, 4 parts of Angelica dahurica, 3 parts of cinnamon, 3 parts of fennel, 4 parts of Piper dial according to the weight components, 5 parts of Xiangguo, 4 parts of Muxiang, 4 parts of Caokou, 4 parts of Tangerine Peel, stir fry in a pot for 3 minutes, smash them, put th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com