Manufacturing method of spicy shredded beef

A production method and technology of shredded beef, applied in the functions of food ingredients, preservation of meat/fish with chemicals, food ingredients as odor modifiers, etc. Strong aroma and long shelf life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

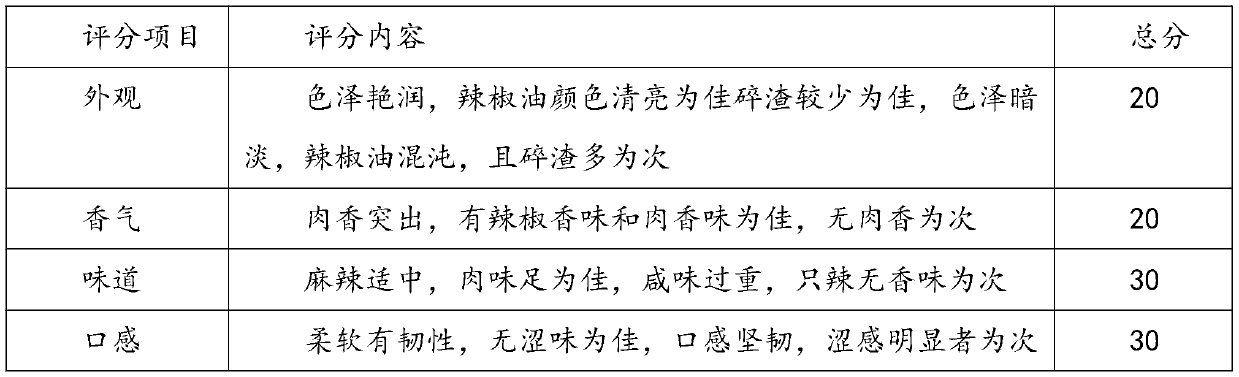

Examples

Embodiment 1

[0040] A preparation method of instant spicy beef is characterized in that it comprises the following steps:

[0041] (1) Beef pretreatment: select beef, remove fat, sarcolemma, lymph, and muscle fiber texture in the meat, cut the beef into pieces, soak in water for 0.5h, rinse blood and sewage, and drain;

[0042] (2) cutting: the beef is cut into 2kg beef pieces along the fiber texture of the meat;

[0043] (3) Cooking: the beef block obtained in step (2) is cooked until obvious obvious fibers appear;

[0044] (4) Cooling: Drain the cooked beef pieces, and then put the meat in the semi-finished product warehouse at a temperature of -18°C for preservation;

[0045] (5) Production of spice packs: Take 5 parts of three Nye, 3 parts of Zanthoxylum bungeanum, 2 parts of clove, 1 part of licorice, 3 parts of star anise, 2 parts of Angelica dahurica, 3 parts of cinnamon, 3 parts of fennel, 4 parts of Piper dial according to the weight components. 3 parts of woody fragrance, 4 par...

Embodiment 2

[0052] (1) Beef pretreatment: select beef, remove fat, sarcolemma, lymph, and muscle fiber texture in the meat, cut the beef into pieces, soak in water for 0.5h, rinse blood and sewage, and drain;

[0053] (2) cutting: the beef is cut into 2kg beef pieces along the fiber texture of the meat;

[0054] (3) Cooking: the beef block obtained in step (2) is cooked until obvious obvious fibers appear;

[0055] (4) Cooling: Drain the cooked beef pieces, and then put the meat in the semi-finished product warehouse at a temperature of -18°C for preservation;

[0056] (5) Production of spice packs: Take 5 parts of Sanye, 4 parts of Zanthoxylum bungeanum, 2 parts of cloves, 2 parts of licorice, 4 parts of star anise, 3 parts of Angelica dahurica, 3 parts of cinnamon, 3 parts of fennel, 4 parts of Piper dial according to the weight components, 4 parts of woody fragrance, 4 parts of tangerine peel, stir-fry in a pot for 4 minutes, break it up, put it in a cloth bag and tie it tightly to make...

Embodiment 3

[0063] (1) Beef pretreatment: select beef, remove fat, sarcolemma, lymph, and muscle fiber texture in the meat, cut the beef into pieces, soak in water for 0.5h, rinse blood and sewage, and drain;

[0064] (2) cutting: the beef is cut into 2kg beef pieces along the fiber texture of the meat;

[0065] (3) Cooking: the beef block obtained in step (2) is cooked until obvious obvious fibers appear;

[0066] (4) Cooling: Drain the cooked beef pieces, and then put the meat in the semi-finished product warehouse at a temperature of -18°C for preservation;

[0067] (5) The production of spice packs: according to the weight components, take 5 parts of three Nye, 5 parts of Chinese prickly ash, 2 parts of clove, 3 parts of licorice, 5 parts of star anise, 4 parts of Angelica dahurica, 3 parts of cinnamon, 3 parts of fennel, 4 parts of Piper dial, 4 parts of woody fragrance, 4 parts of tangerine peel, stir-fry in a pot for 5 minutes, break it up, put it in a cloth bag and tie it tightly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com