Mechanical agricultural watering equipment

A mechanical and agricultural technology, applied in the field of machinery, can solve the problems that water is easy to get on people, water is not easy to get on people, and water cannot be poured evenly on crops.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

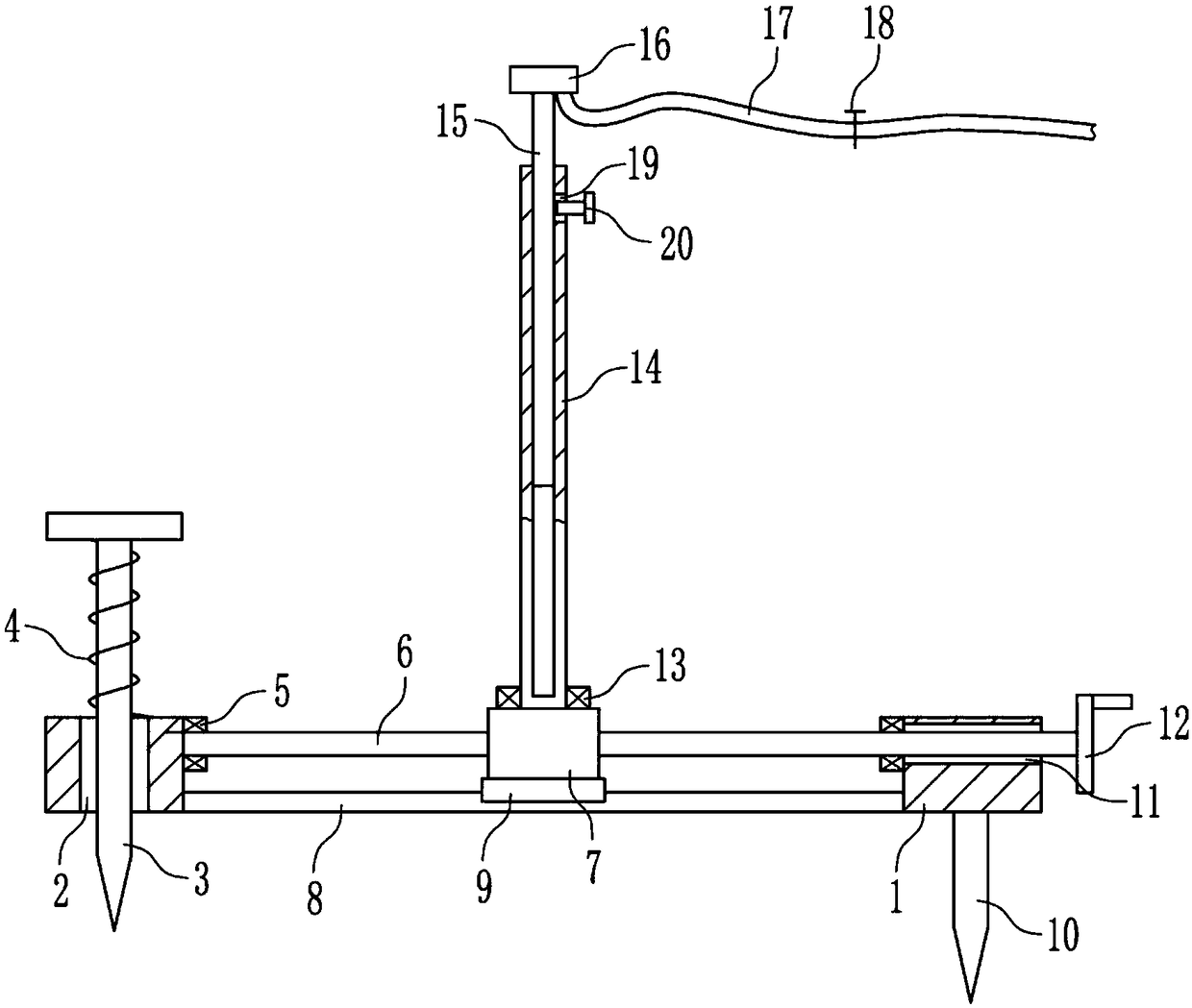

Embodiment 1

[0021] A mechanical agricultural watering equipment, such as Figure 1-3 As shown, it includes a connection block 1, a first insertion rod 3, a spring 4, a first bearing seat 5, a screw rod 6, a nut 7, a slide rail 8, a slider 9, a second insertion rod 10, a rocker 12, a first Two bearing blocks 13, the outer telescopic rod 14, the inner telescopic rod 15, the nozzle 16, the water inlet pipe 17, the valve 18 and the screw rod 20, the middle part of the connecting block 1 on the left side has a through hole 2, and the through hole 2 is provided with a first plug Rod 3, the first insertion rod 3 is covered with a spring 4, the bottom of the spring 4 is connected to the top of the left connection block 1, the top of the spring 4 is connected to the first insertion rod 3, and the upper part of the right connection block 1 has a guide hole 11. The bottom of the connecting block 1 on the right is connected with the second insertion rod 10, and the upper part of the inner side of the...

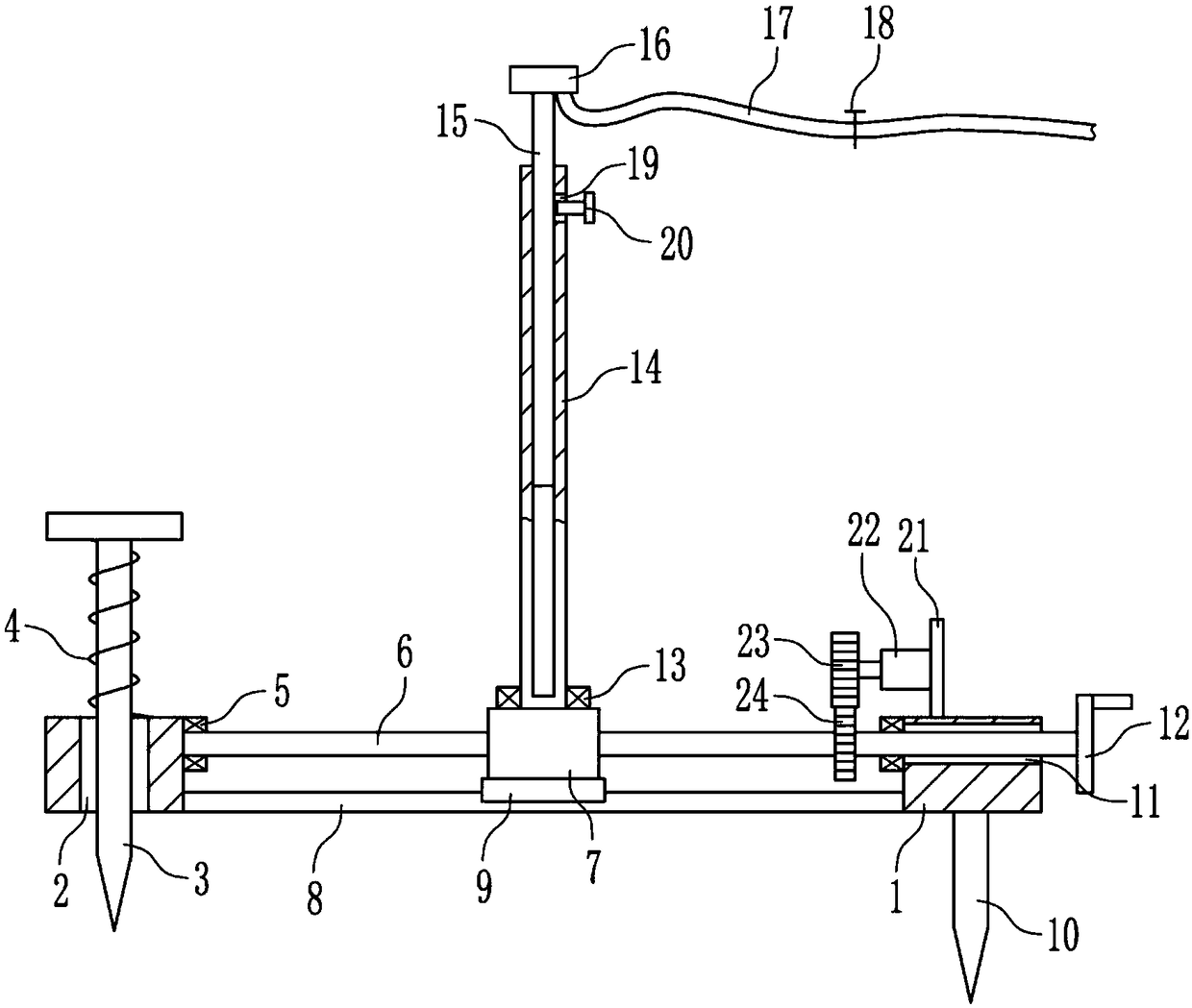

Embodiment 2

[0023] A mechanical agricultural watering equipment, such as Figure 1-3 As shown, it includes a connection block 1, a first insertion rod 3, a spring 4, a first bearing seat 5, a screw rod 6, a nut 7, a slide rail 8, a slider 9, a second insertion rod 10, a rocker 12, a first Two bearing blocks 13, the outer telescopic rod 14, the inner telescopic rod 15, the nozzle 16, the water inlet pipe 17, the valve 18 and the screw rod 20, the middle part of the connecting block 1 on the left side has a through hole 2, and the first plug is arranged in the through hole 2 Rod 3, the first insertion rod 3 is covered with a spring 4, the bottom of the spring 4 is connected to the top of the left connection block 1, the top of the spring 4 is connected to the first insertion rod 3, and the upper part of the right connection block 1 has a guide hole 11. The bottom of the connecting block 1 on the right is connected with the second insertion rod 10, and the upper part of the inner side of the...

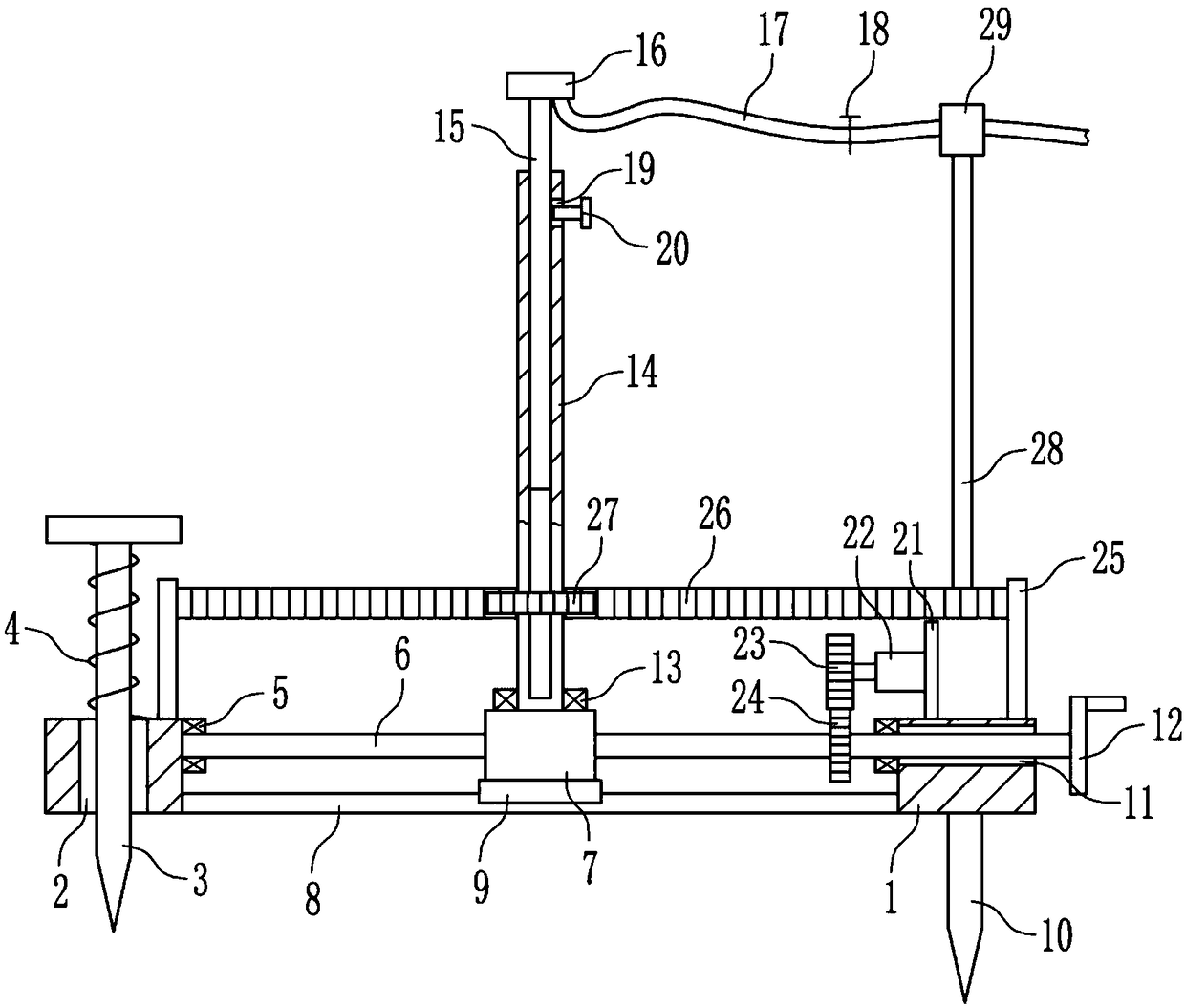

Embodiment 3

[0026] A mechanical agricultural watering equipment, such as Figure 1-3As shown, it includes a connection block 1, a first insertion rod 3, a spring 4, a first bearing seat 5, a screw rod 6, a nut 7, a slide rail 8, a slider 9, a second insertion rod 10, a rocker 12, a first Two bearing blocks 13, the outer telescopic rod 14, the inner telescopic rod 15, the nozzle 16, the water inlet pipe 17, the valve 18 and the screw rod 20, the middle part of the connecting block 1 on the left side has a through hole 2, and the through hole 2 is provided with a first plug Rod 3, the first insertion rod 3 is covered with a spring 4, the bottom of the spring 4 is connected to the top of the left connection block 1, the top of the spring 4 is connected to the first insertion rod 3, and the upper part of the right connection block 1 has a guide hole 11. The bottom of the connecting block 1 on the right is connected with the second insertion rod 10, and the upper part of the inner side of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com