Cable bridge

A technology of cable tray and cable hole, which is applied in the field of power supply equipment, can solve problems such as bridge collapse, cable damage, and cable damage, and achieve the effects of reducing construction progress, reducing manpower, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

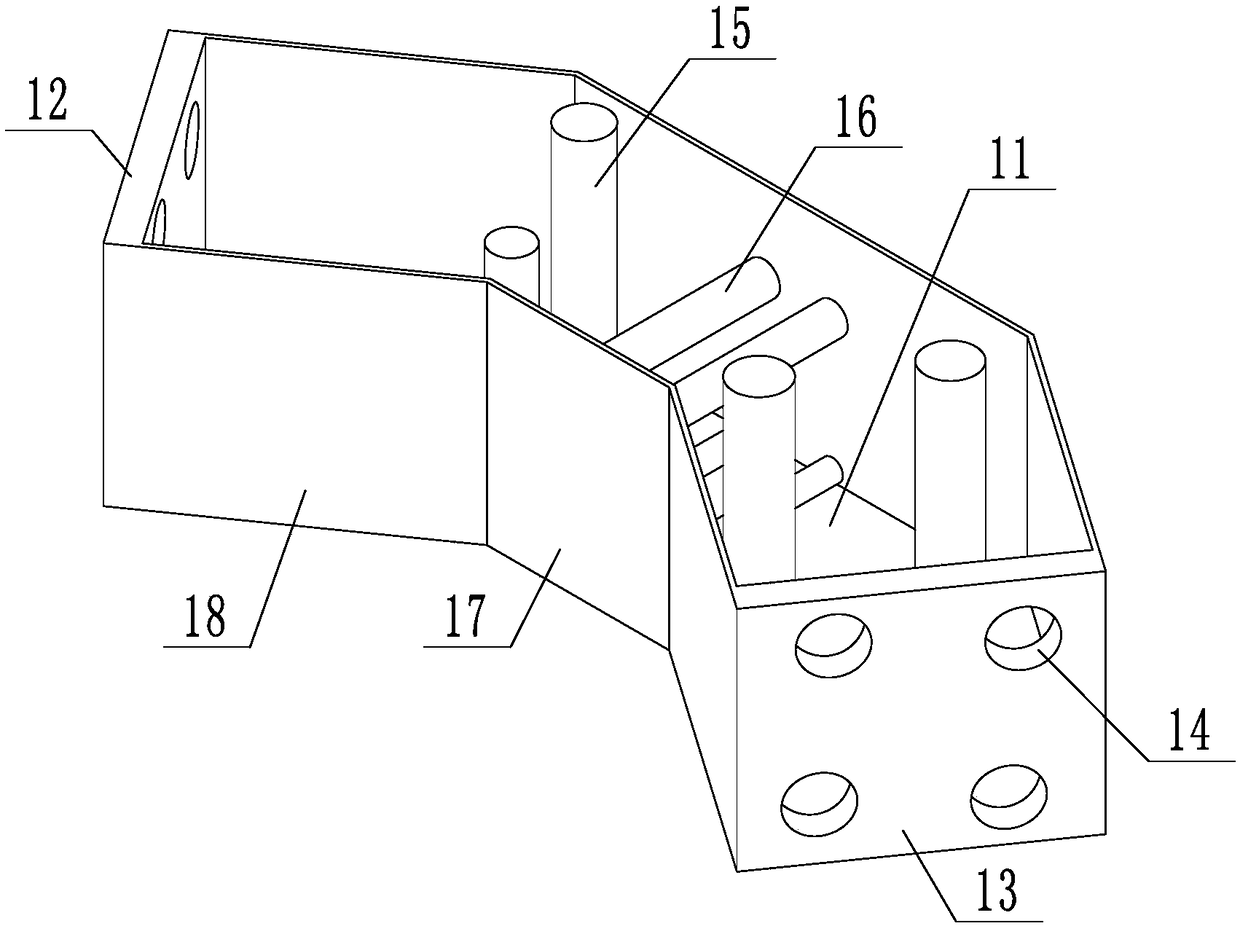

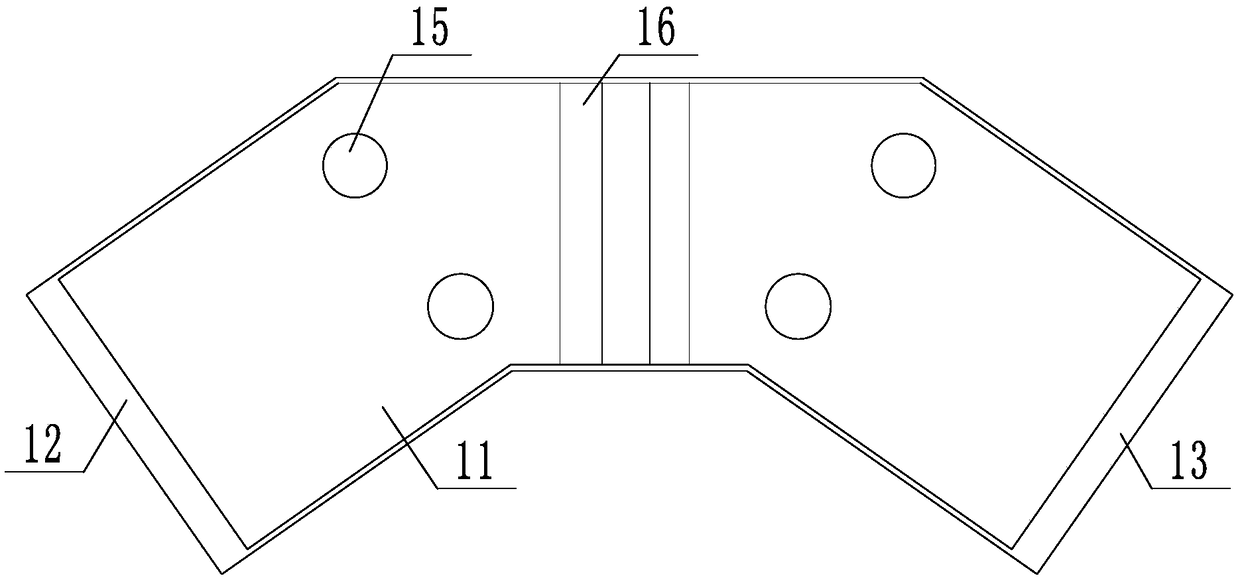

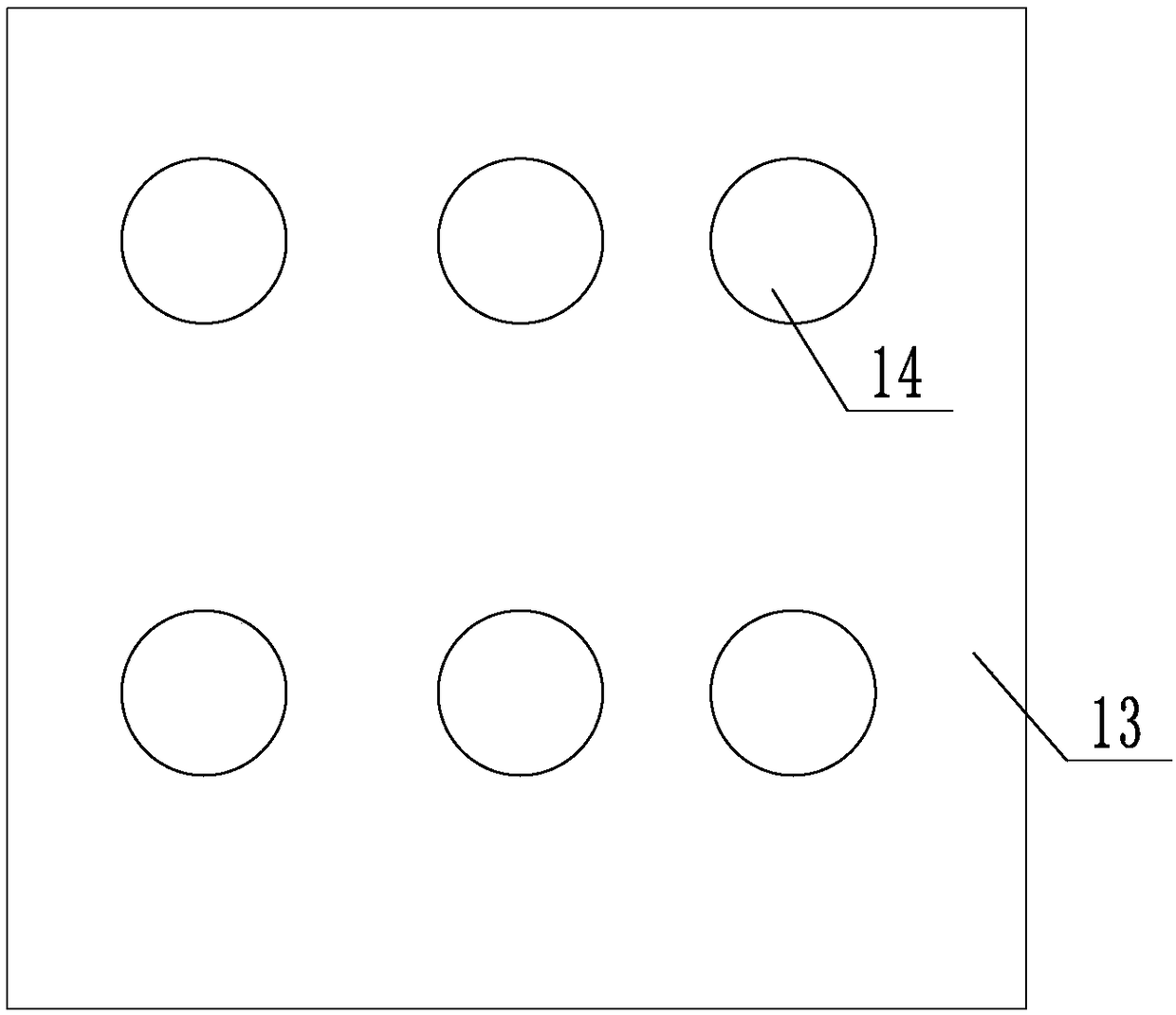

[0029] Such as figure 1 and figure 2 As shown, a cable tray includes a bottom plate 11, and the two ends of the bottom plate 11 are respectively equipped with a first line plate 12 and a second line plate 13, and the first line plate 12 and the second line plate 13 are according to the cable specification and Quantity opens 4-9 cable hole 14, divides two to three layers of layout.

[0030] A plurality of vertical rods 15 are installed on the base plate, and the vertical rods can determine the number of columns of the vertical rods according to the number of rows of the cable holes, for example, if the cable holes are in four rows, then the vertical rods are correspondingly arranged in four rows.

[0031] The vertical rods can be fixed as hangers for fixing the entire bridge frame.

[0032] In the optimal design of the scheme, because the first line plate and the second line plate are under a greater force when pulling the cable, angle irons are installed on both sides of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com