Method for extracting fault signal feature information of aero-engine rotor system

A technology for aero-engine and system failures, which is applied in the direction of engine testing, machine/structural component testing, measuring devices, etc. Problems such as single means

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

[0072] An implementation case of the method for extracting characteristic information of the fault signal of the aeroengine rotor system, including the following process:

[0073] The first step is to collect the rubbing vibration signal of the aero-engine rotor; through the eddy current displacement sensor, select 1000 sets of rubbing vibration signal data samples of the aero-engine rotor at a speed of 2000r / min, and set the sampling frequency of the signal to 1000Hz;

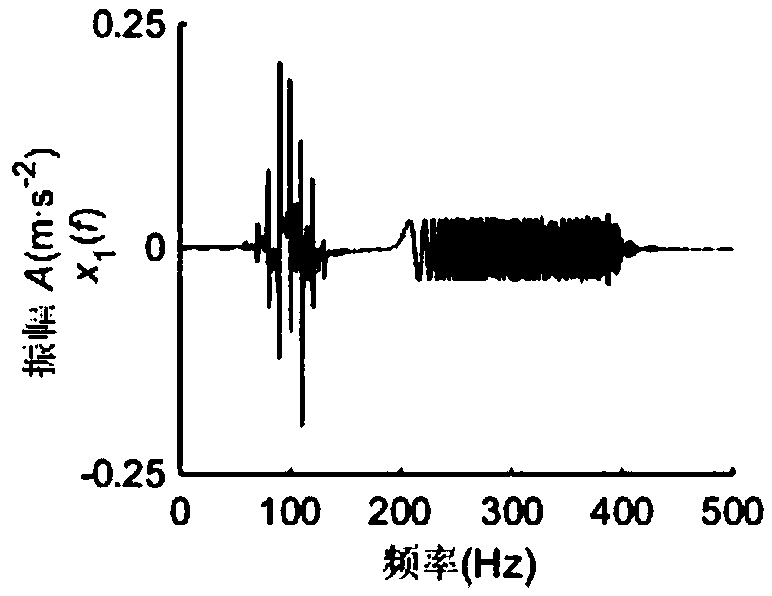

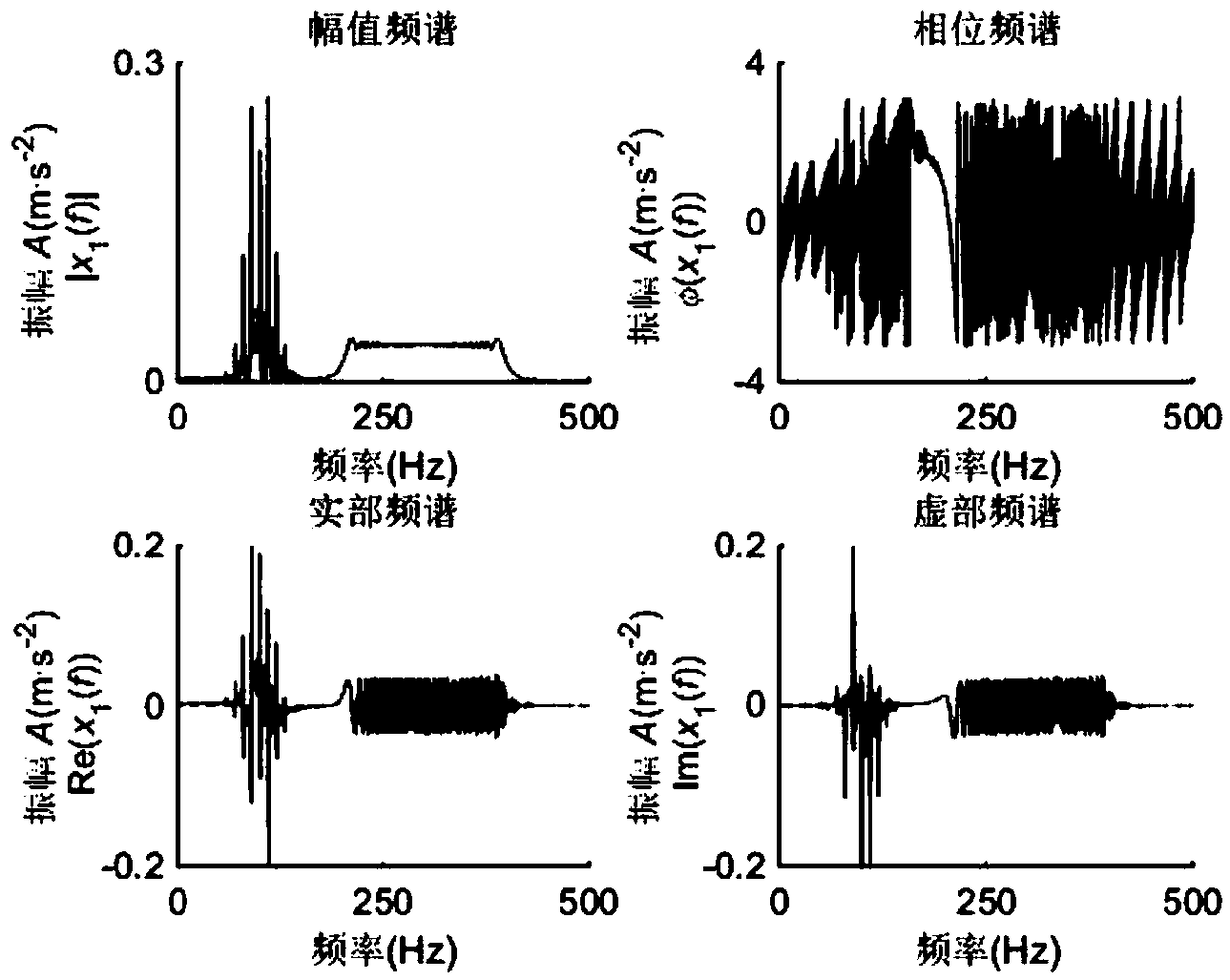

[0074] by formula Construct FM and AM timing simulation signal x 1 (t), simulated signal x 1 (t) contains a non-linear frequency modulation signal x 11 (t) and a frequency-modulated amplitude-modulated signal x with a certain period 12 (t), the sampling frequency of the set signal is 1000Hz;

[0075] signal x 1 The time-domain waveform of (t) is as follows figure 1 shown. Among them, the signal x 1 The waveform diagram of (t) presents complex waveform pulse characteristics without significant periodic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com