Antibacterial stainless steel for handrails or handles

A kind of antibacterial stainless steel, stainless steel technology, applied in the field of stainless steel materials, can solve the problem of low antibacterial efficiency, achieve the effect of increasing antibacterial effect, good antibacterial performance, and improving antibacterial efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

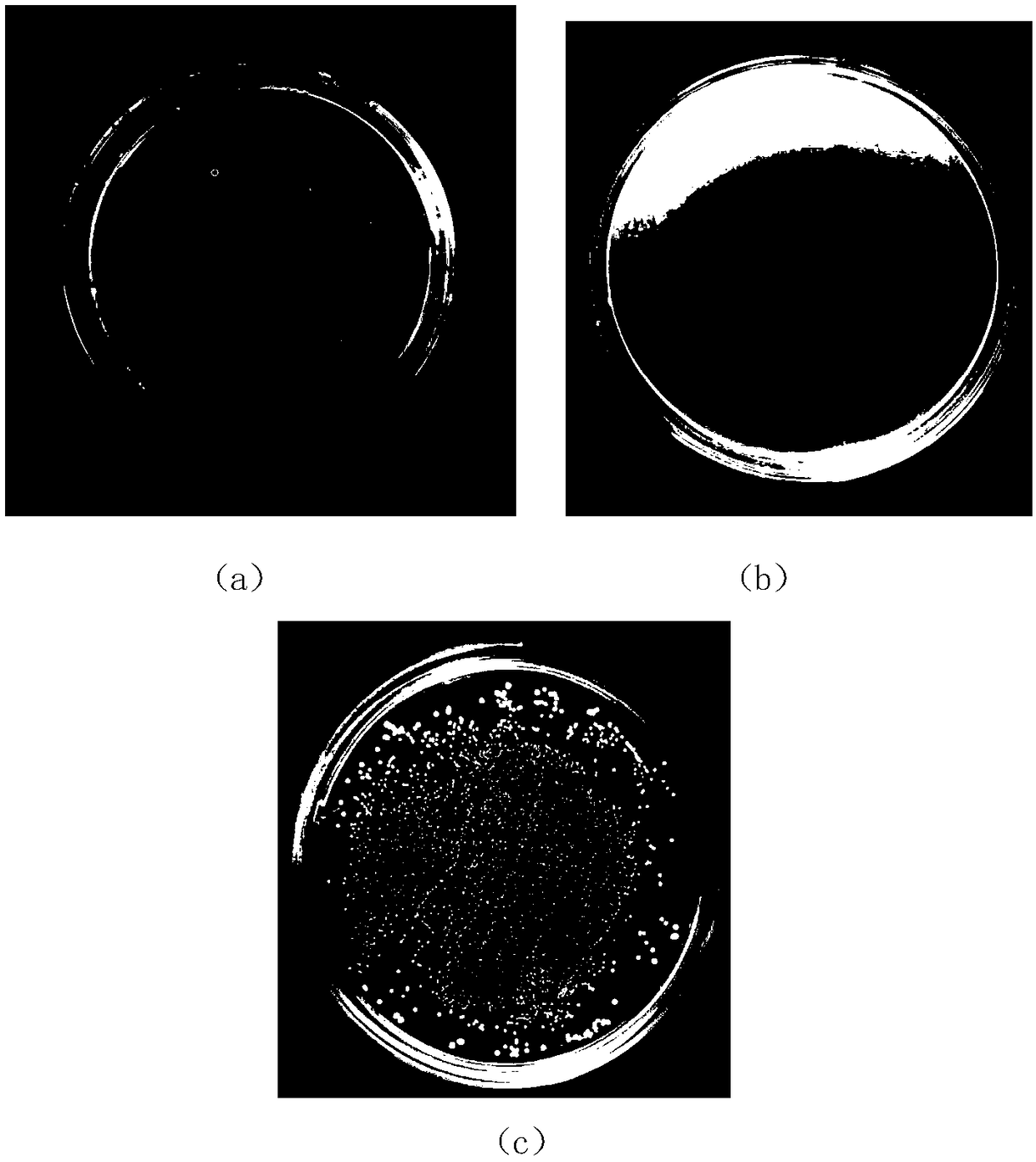

Image

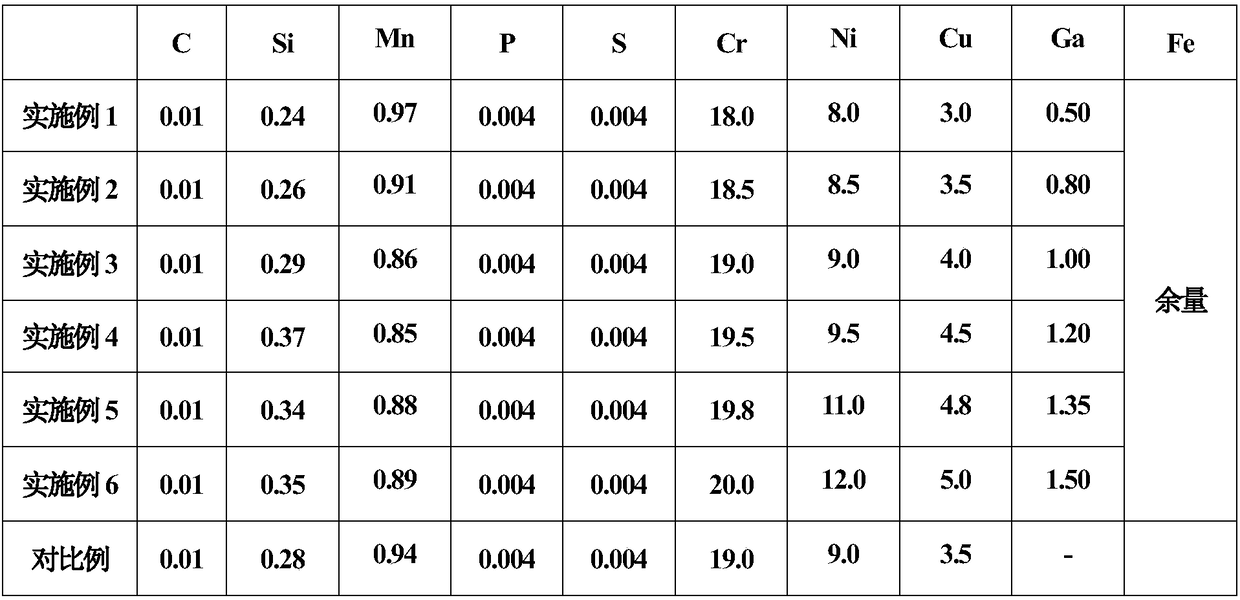

Examples

Embodiment 1

[0027] In this embodiment, the heat treatment process of the antibacterial stainless steel is: heat preservation at 1025° C. for 1 hour, and water cooling to room temperature. According to the above-mentioned antibacterial detection method, the antibacterial performance of typical bacteria is detected, and the result is:

[0028] (1) Antibacterial rate against Eschericher Coli: ≥95.4%;

[0029] (2) Antibacterial rate against Staphyococcus aureus: ≥94.7%.

[0030] The new stainless steel shows excellent antimicrobial properties.

Embodiment 2

[0032] In this embodiment, the heat treatment process of the antibacterial stainless steel is: heat preservation at 1030° C. for 2 hours, and water cooling to room temperature. According to the above-mentioned antibacterial detection method, the antibacterial performance of typical bacteria is detected, and the result is:

[0033] (1) Antibacterial rate against Eschericher Coli: ≥95.8%;

[0034] (2) Antibacterial rate against Staphyococcus aureus: ≥95.6%.

[0035] The new stainless steel shows excellent antimicrobial properties.

Embodiment 3

[0037] In this embodiment, the heat treatment process of the antibacterial stainless steel is: heat preservation at 1030° C. for 3 hours, and then air cooling to room temperature. According to the above-mentioned antibacterial detection method, the antibacterial performance of typical bacteria is detected, and the result is:

[0038] (1) Antibacterial rate against Eschericher Coli: ≥97.4%;

[0039] (2) Antibacterial rate against Staphyococcus aureus: ≥97.2%.

[0040] The new stainless steel shows excellent antimicrobial properties.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com