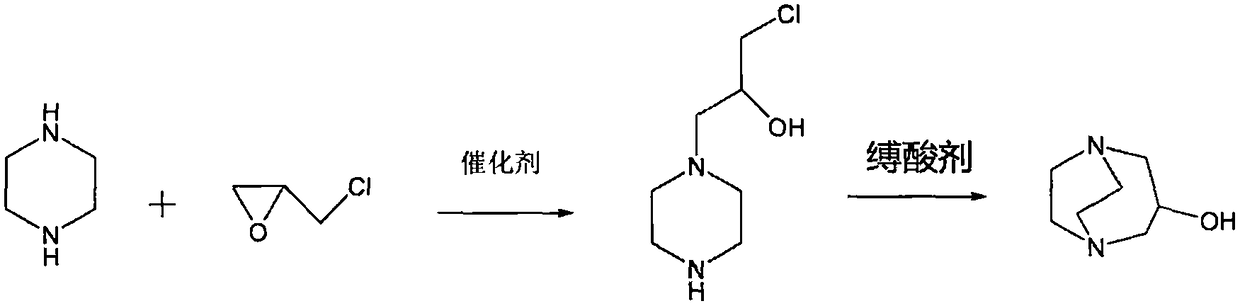

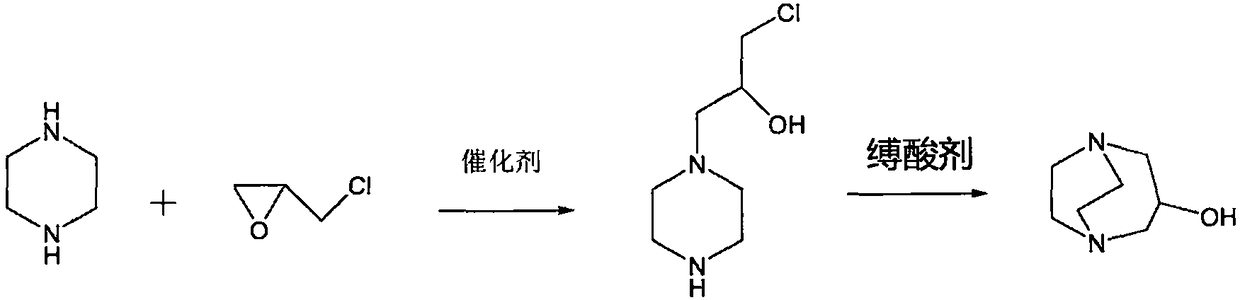

Preparation method of hydroxypropyl diethylenediamine

A technology of hydroxypropyl diethylene diamine and epichlorohydrin, applied in the field of preparation of hydroxypropyl diethylene diamine, can solve the problems of low product yield, complicated process and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example

[0018] The following synthesis examples serve as reference for the preparation method of hydroxypropyldiethylenediamine of the present invention, but the present invention is not limited to the following examples. The chemical reagents used in the following synthesis examples are commercially available analytically pure chemical reagents.

Synthetic example 1

[0020] In the 500 milliliters of four-neck round bottom flasks equipped with stirrer, thermometer and reflux condenser, add respectively the benzyltriethylammonium chloride of 1% of 86 gram piperazine, 200 gram water, reactant weight, be warming up to At 45°C, start to slowly add 95 grams of epichlorohydrin dropwise, and control the temperature below 85°C during the dropwise addition to prevent the temperature from rising sharply. After the dropwise addition, the temperature was raised to reflux, and the reaction was carried out at reflux for 3 hours. After cooling to room temperature, 146 g of 30% sodium hydroxide was added dropwise. After the dropwise addition, the temperature was raised to reflux, and the reaction was carried out at reflux for 8 hours. Then all the water was evaporated, cooled, and then 200 ml of methanol was added, fully stirred, the by-product sodium chloride was filtered out, and the filter cake was washed with methanol. The filtrates were combined, con...

Synthetic example 2

[0022] In the 500 milliliters of four-neck round bottom flasks equipped with stirrer, thermometer and reflux condenser, add respectively the benzyltriethylammonium chloride of 1% of 86 gram piperazine, 200 gram water, reactant weight, be warming up to At 45°C, start to slowly add 95 grams of epichlorohydrin dropwise, and control the temperature below 85°C during the dropwise addition to prevent the temperature from rising sharply. After the dropwise addition, the temperature was raised to reflux, and the reaction was carried out at reflux for 3 hours. After cooling to room temperature, 122 g of triethylamine was added dropwise. After the dropwise addition, the temperature was raised to reflux, and the reaction was carried out at reflux for 6 hours. Then all the water is evaporated, cooled, and then 200 ml of methanol are added, fully stirred, the by-product triethylamine hydrochloride is filtered out, and the filter cake is washed with methanol. The filtrates were combined, c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com