Modified carbon fiber reinforcement asphalt pavement antiskid material and method for preparing same

A fiber-reinforced, asphalt pavement technology, applied in the field of asphalt pavement of highway engineering, can solve the problems of the decay of anti-skid performance of asphalt pavement and poor durability of the surface layer, so as to improve heat resistance, enhance adhesion, improve high temperature stability and The effect of comprehensive mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

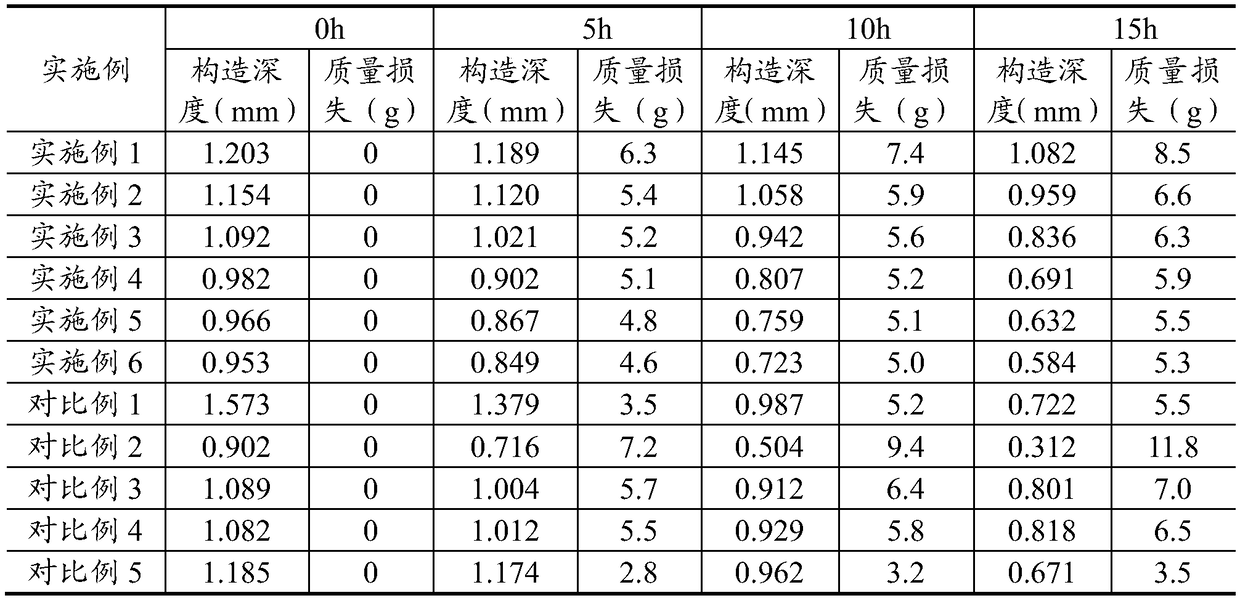

Examples

Embodiment 1

[0037] A modified carbon fiber reinforced asphalt pavement antiskid material, including the following raw materials: 42.6g of surface modified carbon fiber, 2130.7g of SBS modified asphalt epoxy binder, 213.1g of ultrafine organic montmorillonite, and 14914.8g of non-skid aggregate , anti-slip aggregate 27698.9g; among them, SBS modified asphalt epoxy binder contains 80% of SBS modified asphalt, 12% of bisphenol A epoxy resin and 8% of aliphatic polyamine; the material of non-slip aggregate It is limestone, containing 15% of 4.75-9.50mm aggregate, 22% of 2.36-4.75mm aggregate, 22% of 1.18-2.36mm aggregate, 21% of 0.60-1.18mm aggregate and 20% of 0-0.60mm aggregate; The sliding aggregate contains basalt and sintered bauxite with a mass ratio of 1:1, the basalt contains 50% of 4.75-9.50mm aggregate and 50% of 2.36-4.75mm aggregate, and the sintered bauxite contains 50% of 4.75-9.50mm aggregate % and 2.36 ~ 4.75mm aggregate 50%.

[0038] The preparation method of the above-menti...

Embodiment 2

[0045] A modified carbon fiber reinforced asphalt pavement anti-skid material, including the following raw materials: surface modified carbon fiber 42.1g, SBS modified asphalt epoxy binder 2189.0g, ultrafine organic montmorillonite 252.6g, non-skid aggregate 15996.3g , Anti-skid aggregate 26520.1g; Among them, SBS modified asphalt epoxy binder contains 80% of SBS modified asphalt, 12% of bisphenol A epoxy resin and 8% of aliphatic polyamine; the material of non-skid aggregate It is limestone, containing 13% of 4.75-9.50mm aggregate, 20% of 2.36-4.75mm aggregate, 21% of 1.18-2.36mm aggregate, 24% of 0.60-1.18mm aggregate and 22% of 0-0.60mm aggregate; The sliding aggregate contains basalt and sintered bauxite with a mass ratio of 1:1, the basalt contains 50% of 4.75-9.50mm aggregate and 50% of 2.36-4.75mm aggregate, and the sintered bauxite contains 50% of 4.75-9.50mm aggregate % and 2.36 ~ 4.75mm aggregate 50%.

[0046] The preparation method of the above-mentioned modified c...

Embodiment 3

[0053] A modified carbon fiber reinforced asphalt pavement anti-slip material, including the following raw materials: surface modified carbon fiber 84.5g, SBS modified asphalt epoxy binder 2323.9g, ultrafine organic montmorillonite 338.0g, non-slip aggregate 16901.4g , Anti-skid aggregate 25352.1g; Among them, SBS modified asphalt epoxy binder contains 80% of SBS modified asphalt, 12% of bisphenol A epoxy resin and 8% of aliphatic polyamine; the material of non-skid aggregate It is limestone, containing 14% of 4.75-9.50mm aggregate, 21% of 2.36-4.75mm aggregate, 20% of 1.18-2.36mm aggregate, 22% of 0.60-1.18mm aggregate and 23% of 0-0.60mm aggregate; The sliding aggregate contains basalt and sintered bauxite with a mass ratio of 1:1, the basalt contains 50% of 4.75-9.50mm aggregate and 50% of 2.36-4.75mm aggregate, and the sintered bauxite contains 50% of 4.75-9.50mm aggregate % and 2.36 ~ 4.75mm aggregate 50%.

[0054] The preparation method of the above-mentioned modified c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com