Preparation method of doped vanadium dioxide nano-powder

A vanadium dioxide nanometer and powder technology, applied in vanadium oxide, nanotechnology and other directions, can solve the problems of unfavorable environmental protection and industrialized production, high toxicity of raw materials, large amount of waste water, etc., achieves good industrial application prospects, and is easy to prepare in large quantities. , the effect of short time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

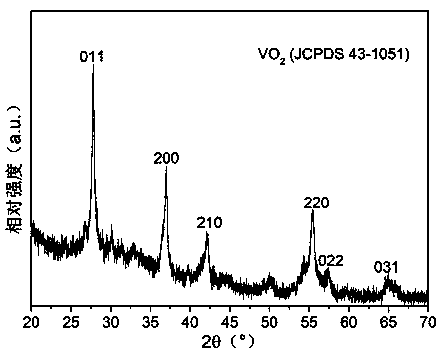

Embodiment 1

[0020] Weigh 5.849 g of ammonium metavanadate and 8.303 g of oxalic acid dihydrate, respectively, and add them to the ball milling tank of the planetary ball mill. After ball milling for 1 hour, take them out, put them in an oven and dry them at 100°C for 2 hours in the air, and then put them into a Calcined at 650°C for 2 hours in a tubular furnace with an atmosphere, and cooled to room temperature to obtain vanadium dioxide nanopowder.

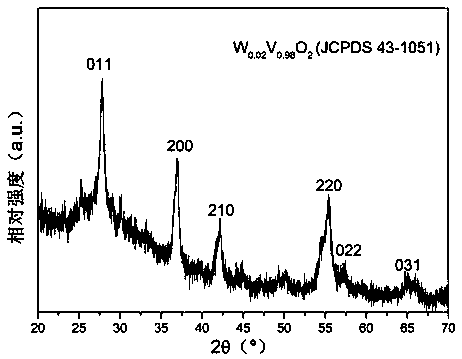

Embodiment 2

[0022] Weigh 5.849 g, ammonium metavanadate, 0.2309 g ammonium paratungstate and 18.909 g oxalic acid dihydrate respectively, add them into the ball milling tank of planetary ball mill, mill for 2 hours, take them out, put them in an oven and dry them in the air at 120°C for 2 hours, then put into a tube furnace with a flowing nitrogen atmosphere and calcined at 600°C for 2 hours, and cooled to room temperature to obtain W 0.02 V 0.98 o 2 Nano powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com