Rotary striking tool

A tool and rotational force technology, applied in the field of rotary hammering tools, can solve problems such as deterioration of torque accuracy and reduction of beating times, and achieve the effects of suppressing deterioration, suppressing abnormal beating, and efficient fastening operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Embodiments of the present invention will be described below in conjunction with the accompanying drawings.

[0052] In this embodiment, as an example of the rotary driving tool of the present invention, a cordless impact driver 1 for fixing screws such as bolts and nuts to be fastened to an object will be described.

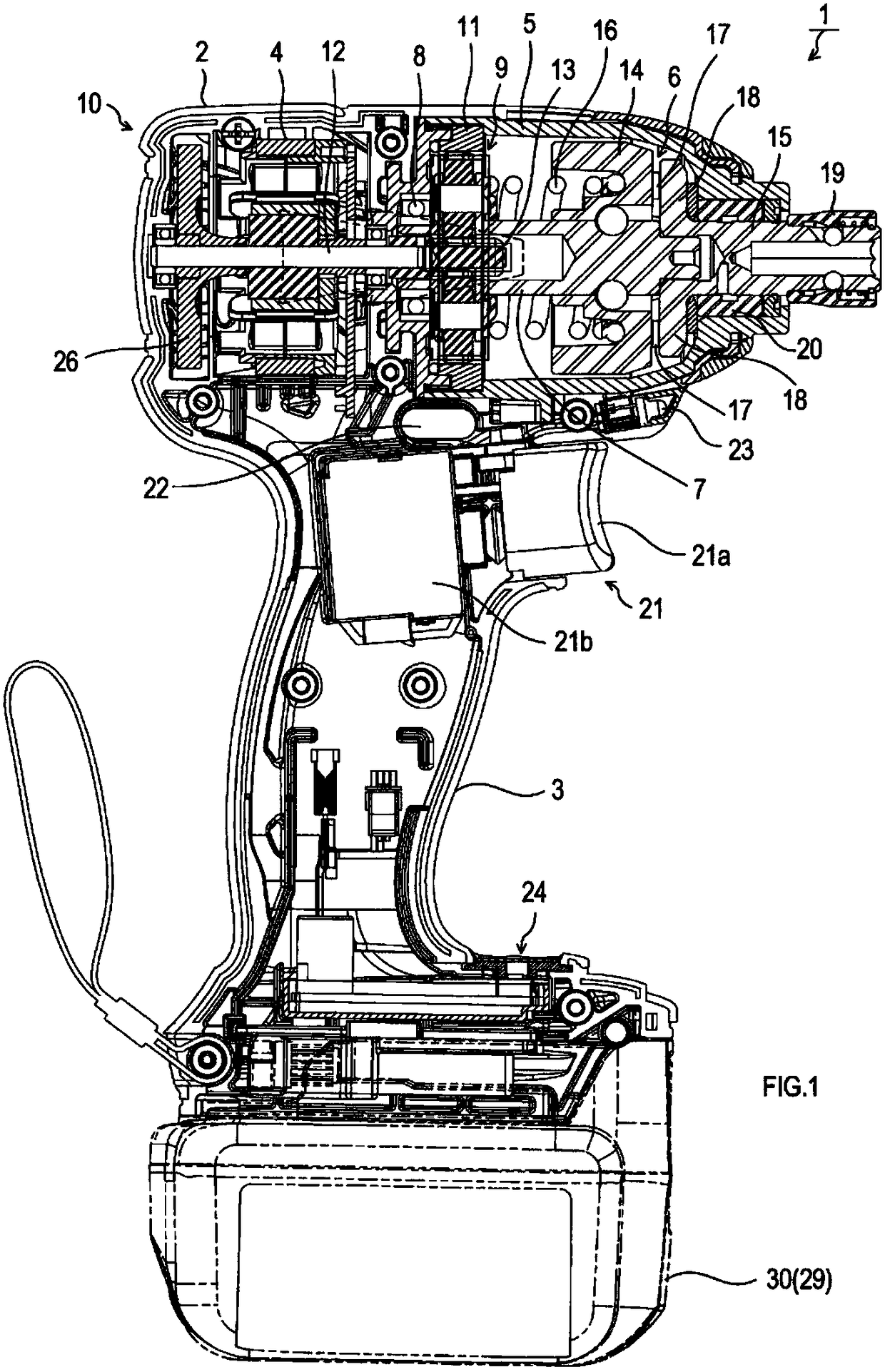

[0053] Such as figure 1 As shown, the cordless impact driver 1 of this embodiment is composed of a tool body 10 and a battery pack 30 that supplies power to the tool body 10 .

[0054] The tool main body 10 is composed of a housing 2 housing a motor 4, a beating mechanism 6, etc. described later, and a lower portion of the housing 2 ( figure 1 The lower side) protrudingly formed handle portion 3 constitutes.

[0055] Inside the housing 2, at its rear ( figure 1 The left side of the motor 4 is housed, and in front of the motor 4 ( figure 1 The right side of the hammer case 5 is assembled with a bell-shaped hammer case 5 , and a striking mechanism 6 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com