Main reinforcement loading device for roll seam welding machine for steel reinforcement framework

A steel skeleton and roll welding machine technology, which is applied in roller electrode welding, welding equipment, resistance welding equipment, etc., can solve the problems of easy bending of the main reinforcement, time-consuming and labor-intensive lifting, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

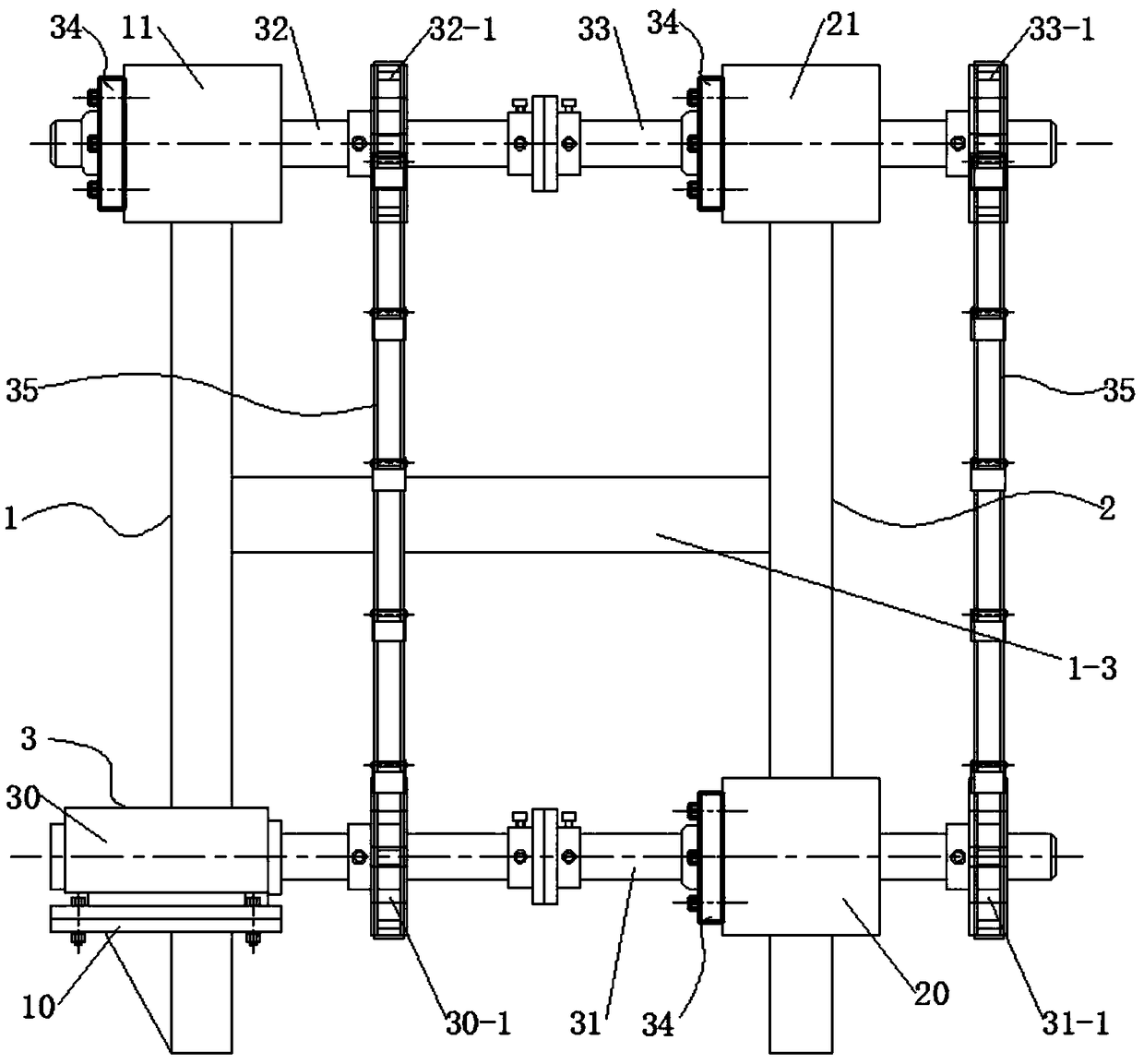

[0025] The main reinforcement feeding device of the steel frame seam welding machine cuts the main reinforcement according to the size, then two workers lift the main reinforcement and place it on the feeding hook 4 on the chain 35, so that the feeding hook 4 supports the main reinforcement, and then Start feeding mechanism 3, motor 30 drives rotating shaft one 31 to rotate, sprocket one 30-1 and sprocket two 31-1 drive sprocket three 32-1 and sprocket four 33-1 with rotating shaft two 32 simultaneously through chain 35 Rotate with the rotating shaft three 33, when the motor 30 drives the chain 35 to move upwards, the main rib is transported obliquely and raised, and then when the feeding hook 4 is transported to the upper end with the main rib, because the chain pin of the feeding hook 4 and the chain 35 Hinged, so feeding hook 4 crosses sprocket wheel three 32-1 and sprocket wheel four 33-1 of upper end with main muscle, when feeding hook 4 crosses sprocket wheel three 32-1 a...

Embodiment 2

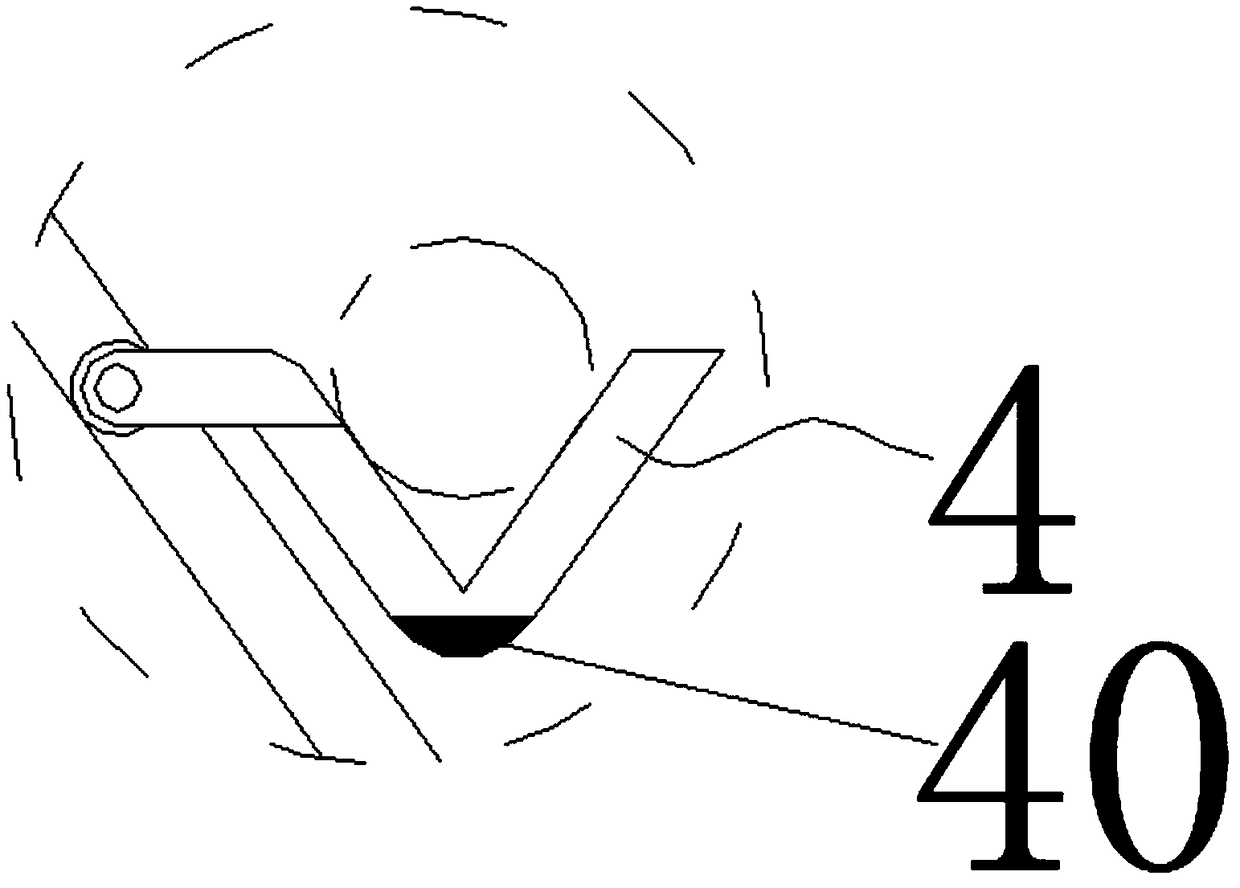

[0027] On the basis of Example 1, the feeding hook 4 is a "V"-shaped structure, which ensures that the hooking of the feeding hook 4 to the main rib is stable; the lower end of the feeding hook 4 is provided with a counterweight 40 to ensure that the upper When the material hook 4 is transported to the obliquely upward section of the upper side, make the "V" shape of the material hook 4 upward, which facilitates the workers to put the main ribs on hold; , and the included angle between the sliding material bar 1-2 and the horizontal plane is 30°-45°, which facilitates the sliding of the main reinforcement to the distribution tray on the guide rail of the steel bar skeleton roll welding machine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com