Forming device and method of complex inner wall and outer wall cylindrical part

A wall tube, complex technology, applied in the direction of molding tools, other household appliances, household appliances, etc., can solve the problems of affecting production efficiency, difficult demoulding, etc., to achieve the effect of convenient demoulding process, less loss of raw materials, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

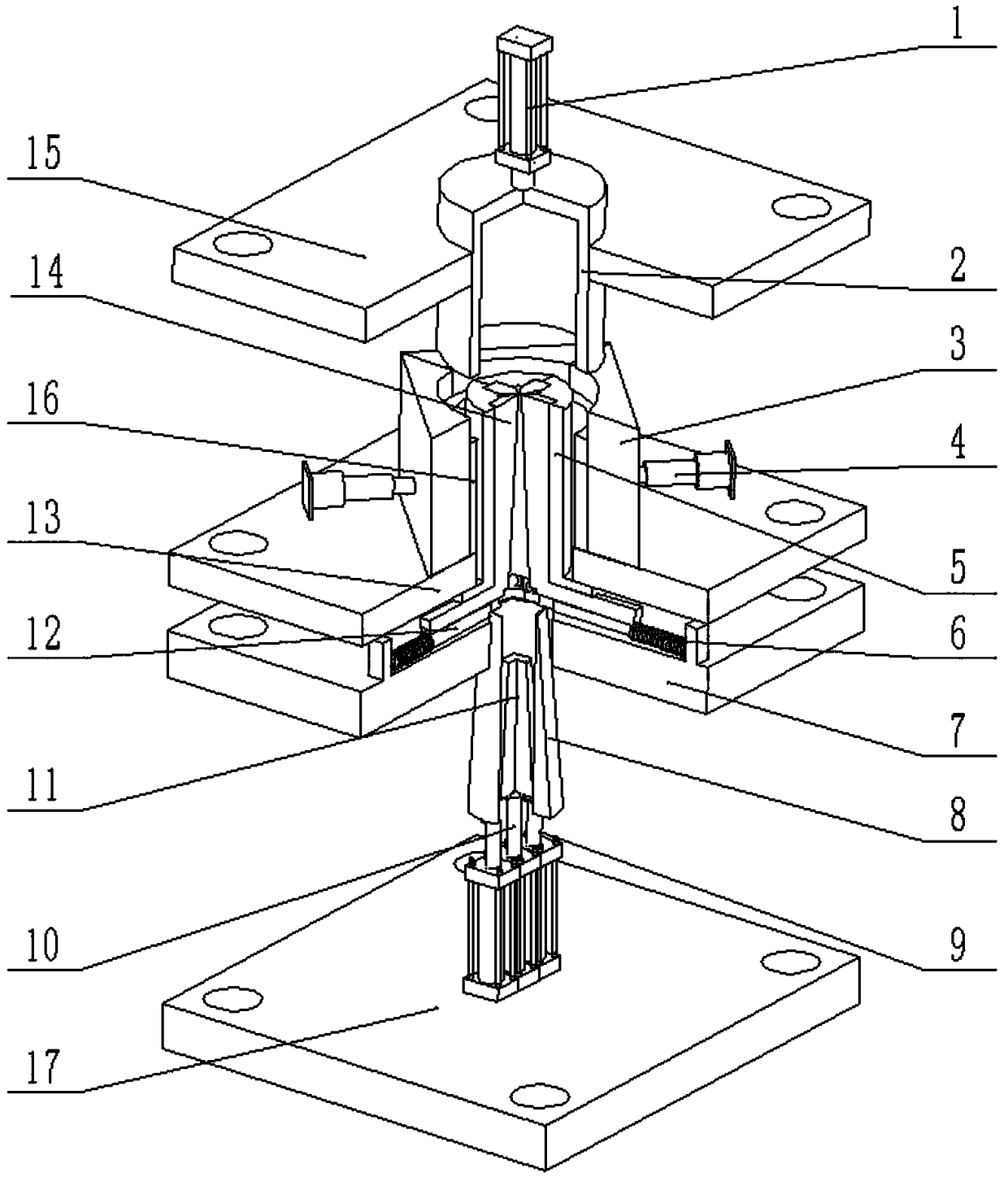

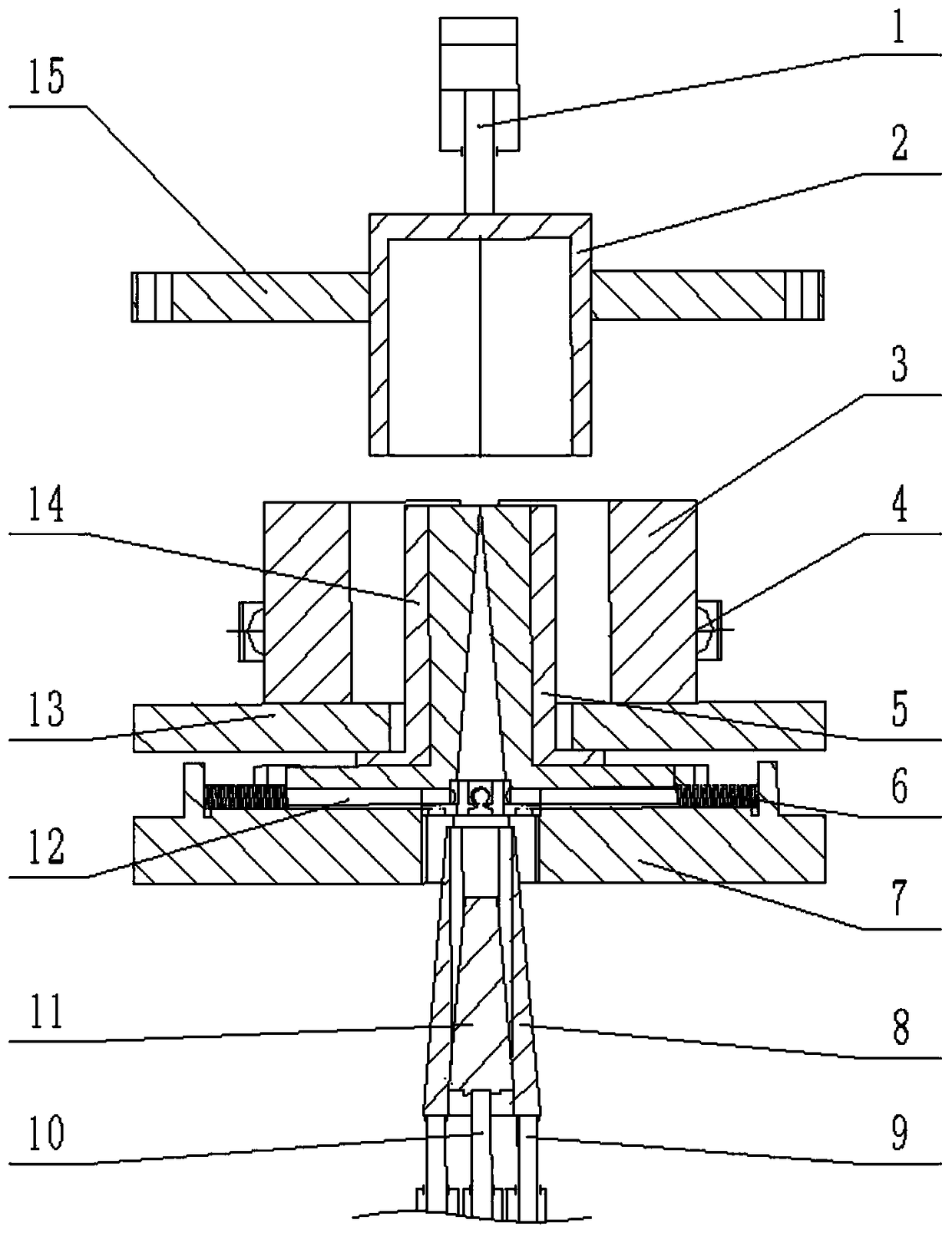

[0035] The formed part is a cylindrical part with spiral ribs on the inner and outer walls, such as Figure 6 shown. select as figure 2 The cylindrical piece shown is used as the forming blank; the shape of the outer wall of the cylindrical piece is formed by a four-petal die with a spiral shape inside, and the shape of the four-petal die is as follows Figure 7 As shown; the shape of the inner wall of the cylindrical part is formed by selecting the inner and outer valve molds with a spiral shape outside, and the shape of the inner and outer valve molds is as follows Figure 8 shown.

[0036] Step 1, the multi-lobe die set on the die fixing plate realizes synchronous mold clamping movement under the control of the die drive cylinder; the inner mandrel moves vertically upwards through the drive of the inner mandrel ejection cylinder until the inner mandrel The ejector cylinder is in contact with the inner cavity surfaces of the four inner valve molds, and by utilizing the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com