Heat dissipation and dust removal device for electromechanical equipment

A technology of electromechanical equipment and dust removal device, which is applied to the construction of electrical equipment components, smoke and dust removal, cleaning methods using tools, etc., can solve problems such as dust prone to failure, affect heat dissipation effect, and ignore dust removal, etc., to protect the environment , Improve the heat dissipation effect and reduce the temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

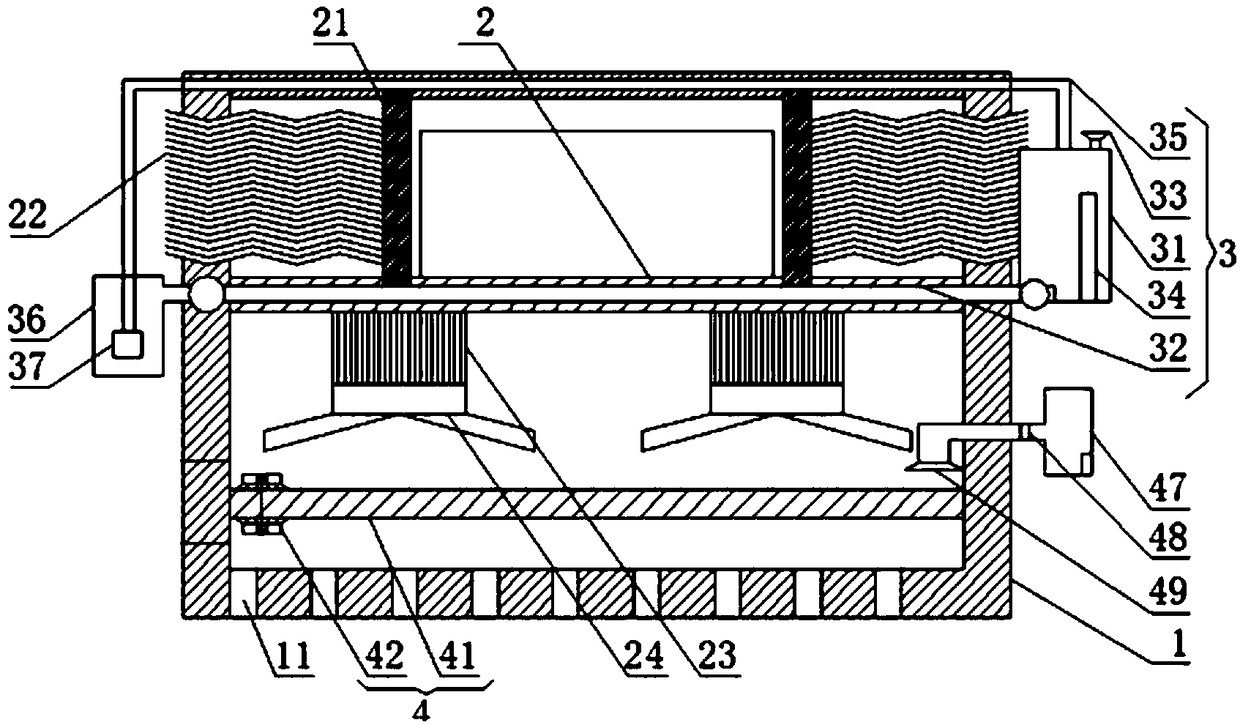

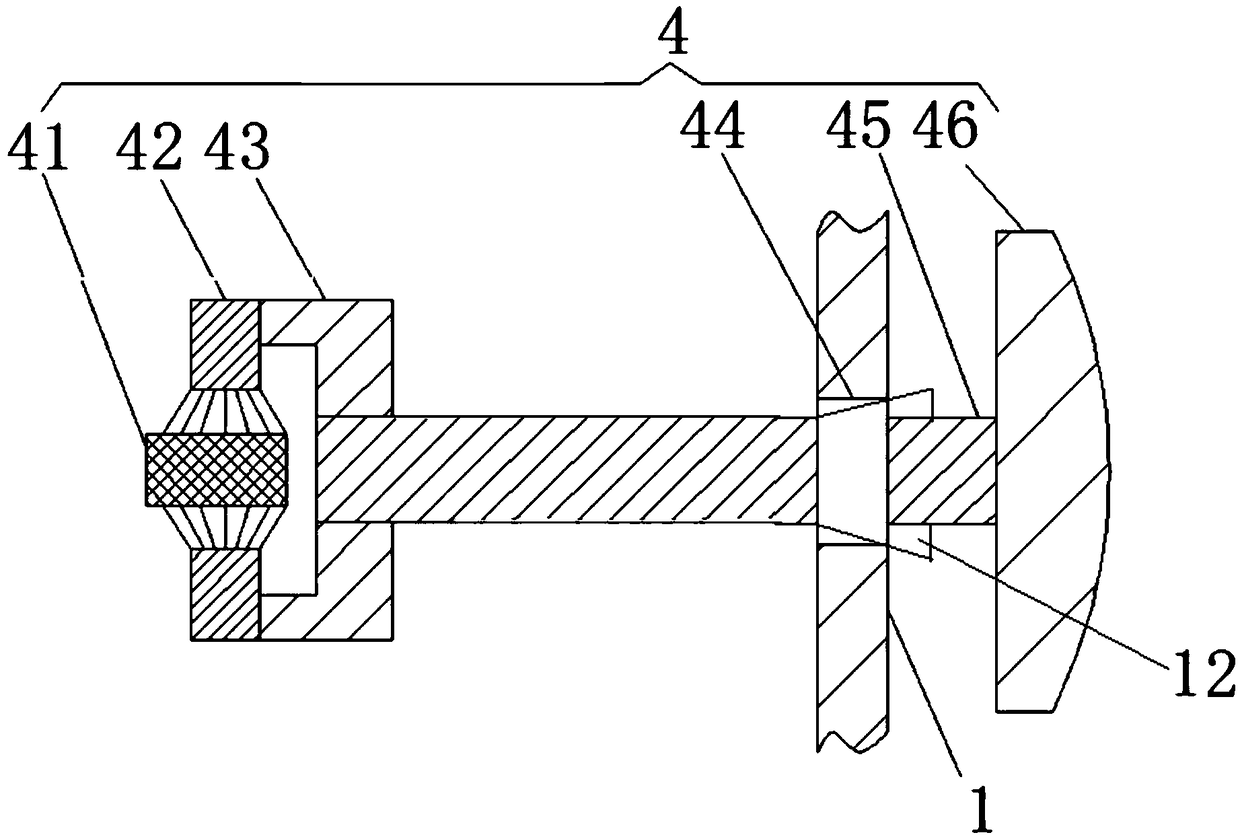

[0028] A heat dissipation and dust removal device for electromechanical equipment, its structure is as follows figure 1 , figure 2 As shown, including the shell 1, the inner wall of the bottom plate of the shell 1 is separately provided with several through holes 11, and the heat can be discharged from the through holes 11. The inner cavity side wall of the shell 1 is fixedly installed with a mounting plate 2, and 2 is a metal heat-conducting material, and the top outer wall of the mounting plate 2 is symmetrically fixed with two side plates 21, and a number of heat-conducting wires 22 are fixedly installed on the side of the two side plates 21 close to the shell 1, and each heat-conducting wire 22 is wavy. In addition, the end of each heat conducting wire 22 away from the side plate 21 extends to the outside through the shell 1, the heat conducting wire 22 can improve the heat dissipation effect of the side plate 21, and the tops of the two side plates 21 are fixedly connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com