Intelligent gear with state perception function

A state-aware, gear technology, applied in the direction of components with teeth, belts/chains/gears, hoisting devices, etc., can solve the problems of small installation space, less original signal components, and large noise interference, so as to reduce the installation space. The influence of the sensor, the perceived signal strength, the effect of overcoming the mechanical environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

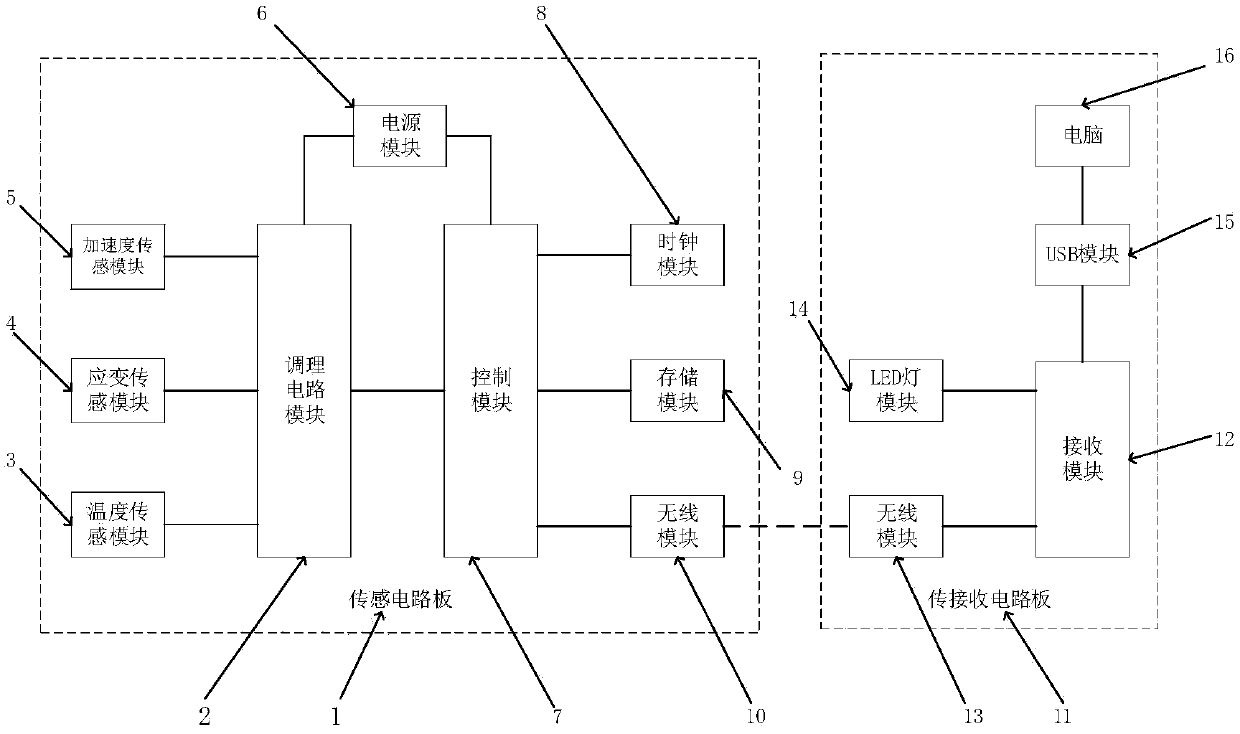

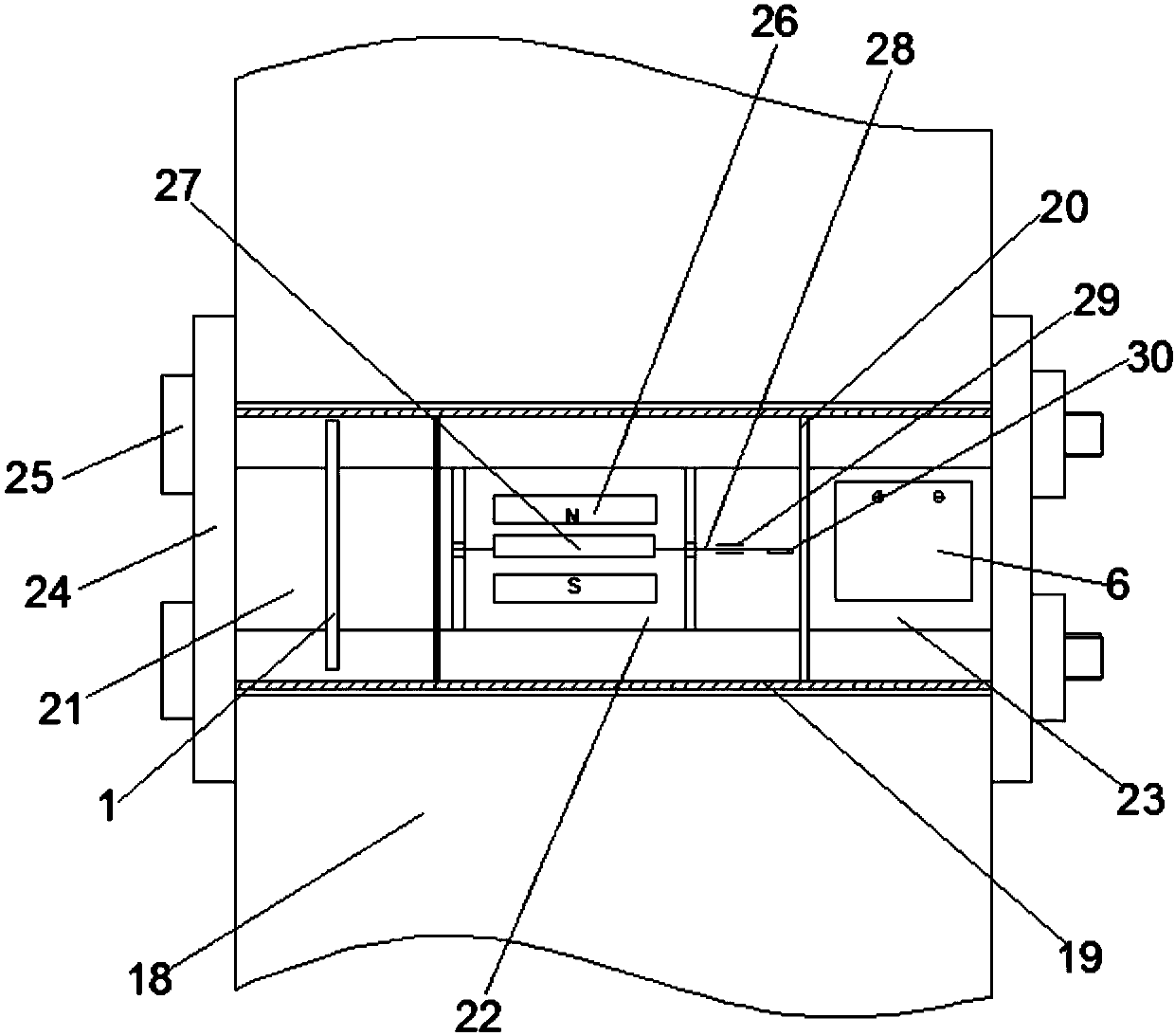

[0026] Such as Figure 1-3 It is a schematic diagram of the structure of the smart gear with state sensing function before starting; the invention discloses a smart gear with state sensing function, including a gear 18 and a pair of counterweight holes arranged on the gear 18, and a counterweight A transmission state monitoring device is provided in the hole, and a corresponding counterweight 17 is provided in the other counterweight hole. The transmission state monitoring device includes a housing 19, a sensor circuit board 1 and a power supply arranged in the housing 19. Unit 6, the sensor circuit board 1 is provided with a conditioning circuit unit 2, a control unit 7, a clock unit 8, a storage unit 9 and a wireless transmitting unit 10, the signal 2 outlet of the conditioning circuit unit is connected to the control unit 7, the The con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com