Warp-knitting elastic zigzag-design thermal fabric and production method thereof

A production method and technology of herringbone pattern, applied in warp knitting, textiles, papermaking, knitting and other directions, can solve problems such as difficulty in adapting to the dimensional stability requirements of clothing, achieve obvious herringbone pattern effect, improve elastic recovery, and process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] In the production method of the above-mentioned warp-knitted elastic herringbone pattern thermal fabric, the single-comb structure and threading mode of the complete machine and weaving are:

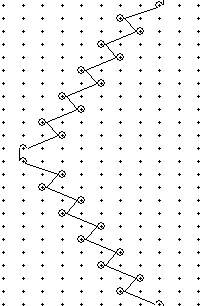

[0056] Such as figure 1 Shown, GB1 comb: 0- 1 / 2- 3 / 2- 1 / 3- 4 / 3- 2 / 4- 5 / 4- 3 / 5- 6 / 5- 4 / 6-7 / 6- 5 / 7- 8 / 8- 7 / 6- 5 / 6- 7 / 5- 4 / 5- 6 / 4- 3 / 4- 5 / 3- 2 / 3- 4 / 2- 1 / 2-3 / 1- 0 / / ,1A1B;

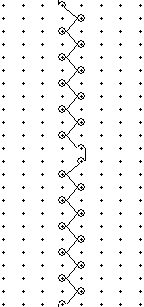

[0057] Such as figure 2 Shown, GB2 comb: 2- 1 / 1- 0 / 1- 2 / 1- 0 / 1- 2 / 1- 0 / 1- 2 / 1- 0 / 1- 2 / 1-0 / 1- 2 / 1- 0 / 0- 1 / 2 / 1- 0 / 1- 2 / 1- 0 / 1- 2 / 1- 0 / 1- 2 / 1- 0 / 1- 2 / 1- 0 / 1- 2 / / , 2C;

Embodiment 2

[0059] In the production method of the above-mentioned warp-knitted elastic herringbone pattern thermal fabric, the single-comb structure and threading mode of the complete machine and weaving are:

[0060] GB1 comb: 0- 1 / 2- 3 / 2- 1 / 3- 4 / 3- 2 / 4- 5 / 4- 3 / 5- 6 / 5- 4 / 6- 7 / 6- 5 / 7- 8 / 7-6 / 8- 9 / 9-8 / 7-6 / 7-8 / 6- 5 / 6- 7 / 5- 4 / 5- 6 / 4- 3 / 4- 5 / 3- 2 / 3 - 4 / 2-1 / 2- 3 / 1- 0 / / , 1A1B;

[0061] GB2 comb: 2- 1 / 1- 0 / 1- 2 / 1- 0 / 1- 2 / 1- 0 / 1- 2 / 1- 0 / 1- 2 / 1- 0 / 1- 2 / 1- 0 / 1-2 / 1-0 / 0-1 / 1-2 / 1- 0 / 1- 2 / 1- 0 / 1- 2 / 1- 0 / 1- 2 / 1- 0 / 1- 2 / 1 - 0 / 1-2 / 1-0 / 1-2 / / , 2C;

Embodiment 3

[0063] In the production method of the above-mentioned warp-knitted elastic herringbone pattern thermal fabric, the single-comb structure and threading mode of the complete machine and weaving are:

[0064] GB1 comb: 0- 1 / 2- 3 / 2- 1 / 3- 4 / 3- 2 / 4- 5 / 4- 3 / 5- 6 / 5- 4 / 6- 7 / 7-6 / 5- 4 / 5- 6 / 4- 3 / 4- 5 / 3- 2 / 3- 4 / 2- 1 / 2- 3 / 1- 0 / / , 1A1B;

[0065] GB2 comb: 2- 1 / 1- 0 / 1- 2 / 1- 0 / 1- 2 / 1- 0 / 1- 2 / 1- 0 / 1- 2 / 1- 0 / 0-1 / 1- 2 / 1-0 / 1-2 / 1- 0 / 1- 2 / 1- 0 / 1- 2 / 1- 0 / 1- 2 / / , 2C.

[0066] The weight per square meter of the finished warp-knitted elastic herringbone thermal fabric is 339-353g / m2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com