Copper wire shearing device

A copper wire and wire trimming technology, which is applied in the field of copper wire trimming devices, can solve the problems of increased labor costs and low processing efficiency, and achieve the effects of convenient post-welding, small length error, and reduced space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described now in conjunction with accompanying drawing.

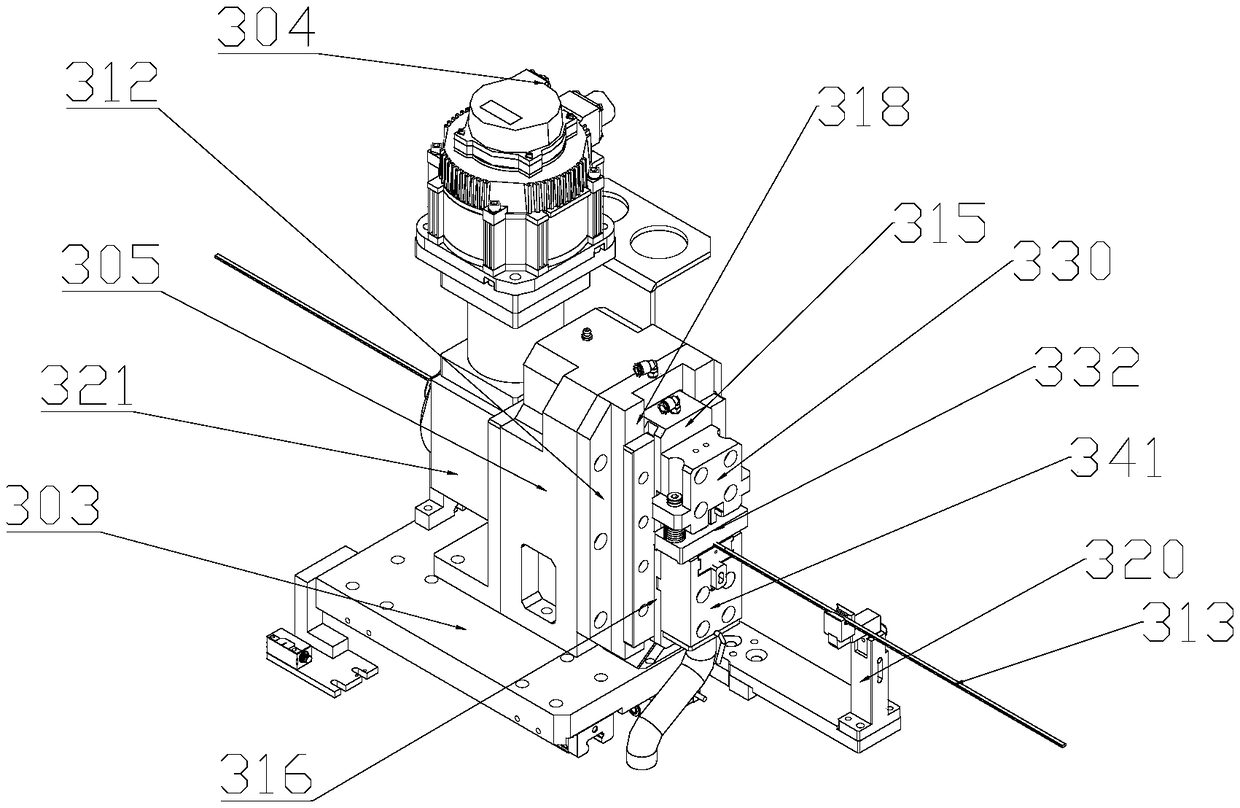

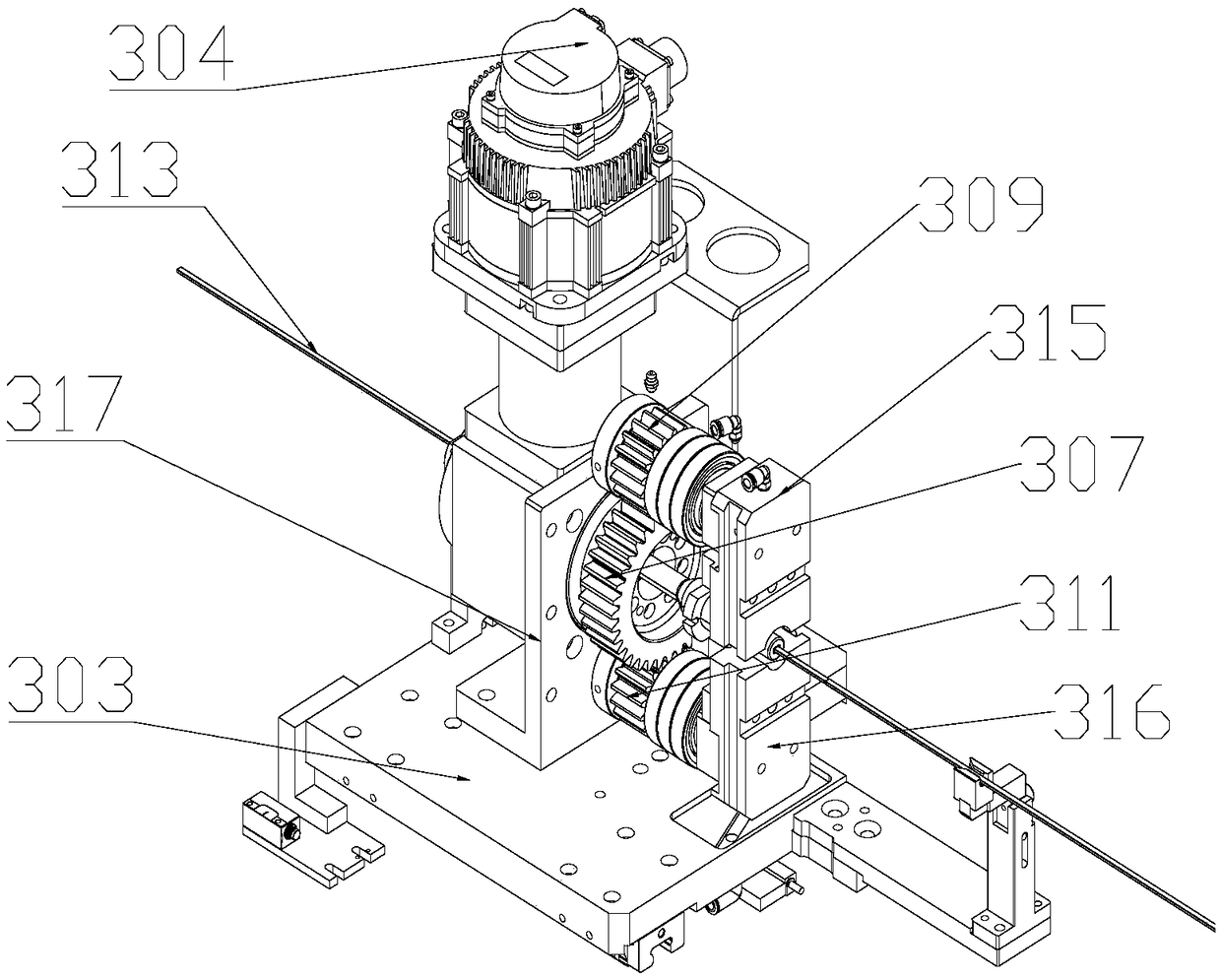

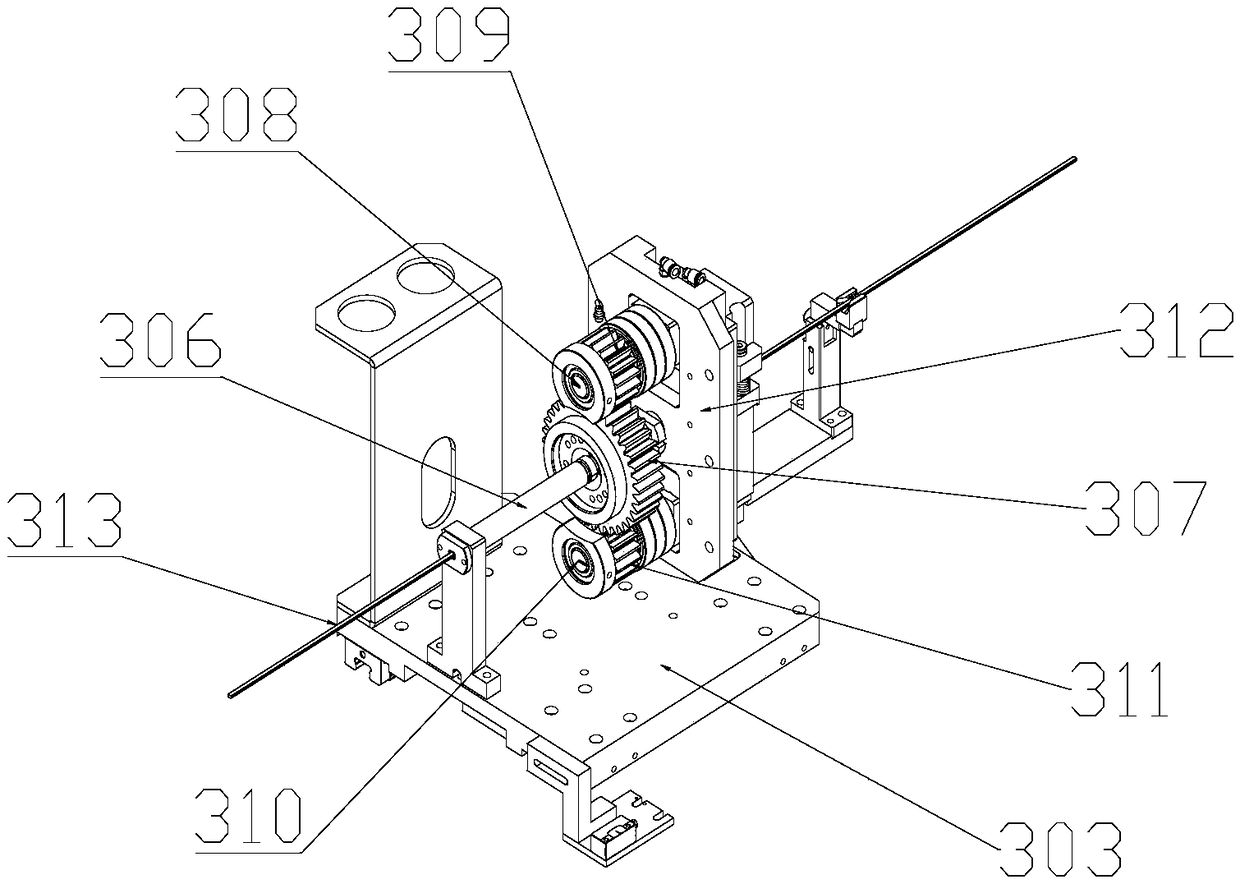

[0023] Such as Figure 1-5 As shown, the copper wire trimming device includes a power mechanism and a scissors mechanism. The power mechanism includes a wire trimming base 303, a power motor 304, and a gear box 305. The gear box 305 is fixed on the wire trimming base 303, and the gear The box 305 is provided with a hollow shaft 306, a middle gear 307 installed on the hollow shaft 306, an upper rotating shaft 308, an upper gear 309 installed on the upper rotating shaft 308, a lower rotating shaft 310, a lower gear 311 installed on the lower rotating shaft 310, the gear Case 305 includes front side plate 317 and rear side plate 312, and the two ends of hollow shaft 306, upper rotating shaft 308 and lower rotating shaft 310 are rotatably installed on the front side plate and rear side plate 312 respectively by bearing, the hollow shaft 306 The two ends respectively expose the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com