A thread trimmer drive mechanism for a sewing machine

A driving mechanism and a technology for a sewing machine, which are applied to a thread cutting mechanism in a sewing machine, a sewing machine element, a control device for a sewing machine, etc., can solve the problems of occupying the interior installation space of a sewing machine table, complicated structure of the sewing machine table, and increased production costs, etc. Achieve the effect of saving installation space, saving thread trimming time and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

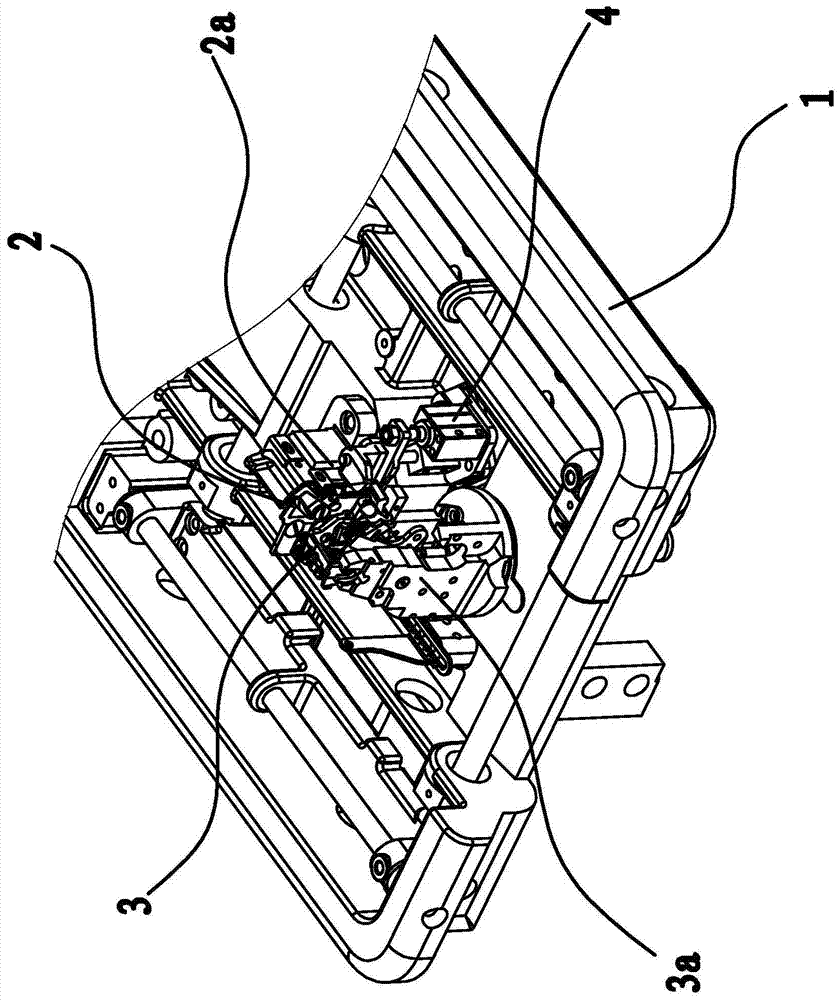

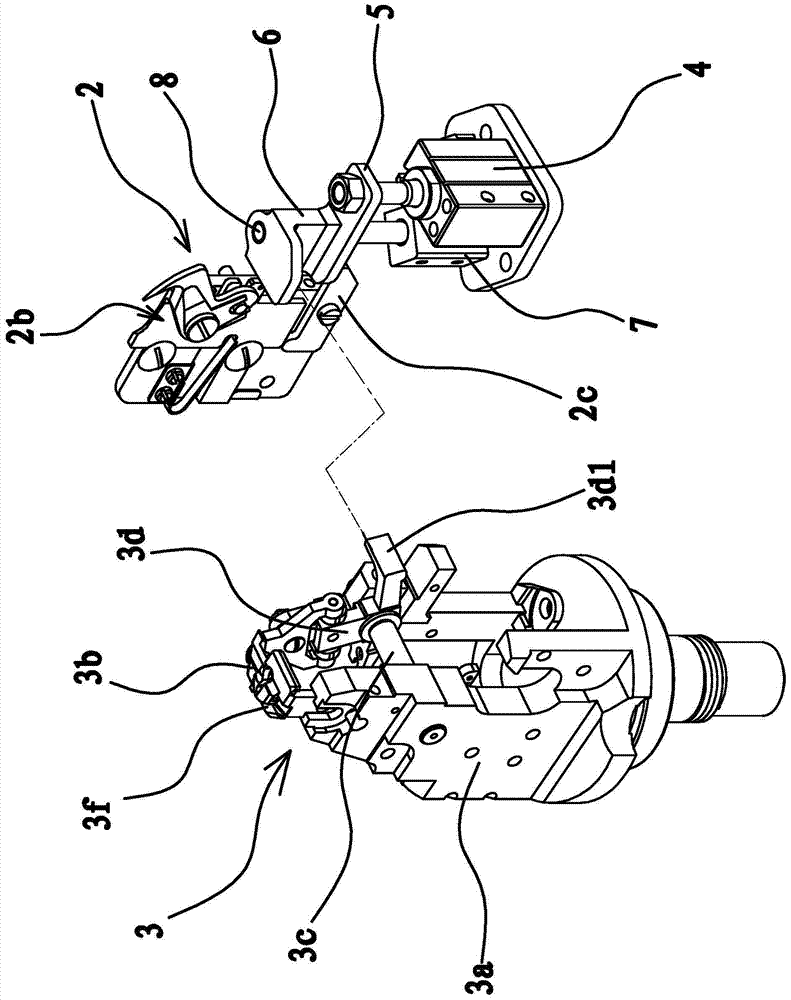

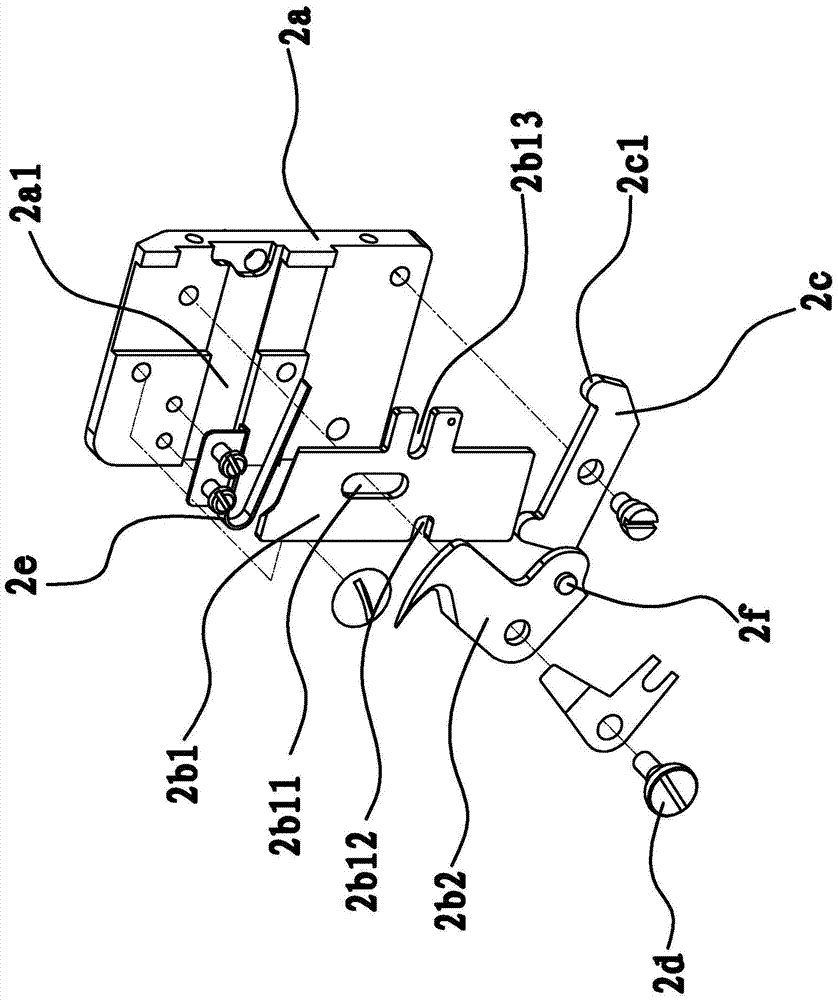

[0038] Such as figure 1 and figure 2 As shown, a thread trimming driving mechanism of a sewing machine includes an upper thread trimming mechanism 3 , a bottom thread trimming mechanism 2 and a driving cylinder 4 arranged in a sewing machine table 1 . The bobbin thread cutting mechanism 2 includes a base 2a fixed in the sewing machine table 1. Bottom thread scissors 2b are vertically arranged on the base 2a. A transmission rod 2c is arranged below the bottom thread scissors 2b. The middle part of the transmission rod 2c is hinged on the base 2a. , the inner end of the transmission rod 2c abuts against the bottom of the bobbin thread scissors 2b. The end of the driving cylinder 4 is horizontally connected with a pressing plate 5, the outer end of the pressing plate 5 is connected with the piston rod of the driving cylinder 4, and the inner end of the pressing plate 5 abuts against the outer end of the transmission rod 2c. In this embodiment, there are protrusions 2c1 on both...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com