Ammonia working medium liquid distributor

A liquid distributor and working medium technology, applied in refrigeration and liquefaction, mechanical equipment, fluid circulation arrangement, etc., to achieve good gas-liquid mixing uniformity, improve continuity, and reduce the effect of liquid storage volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

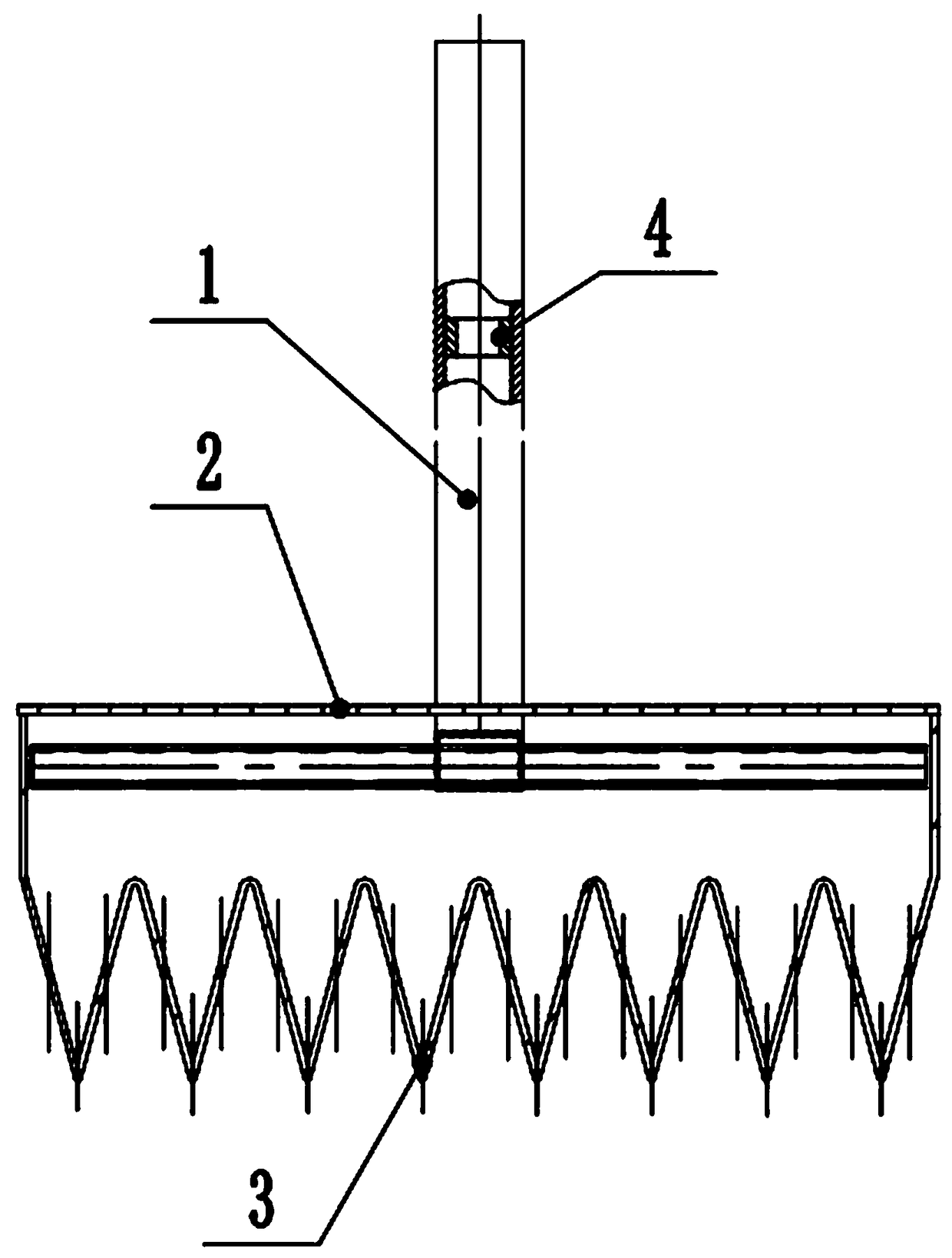

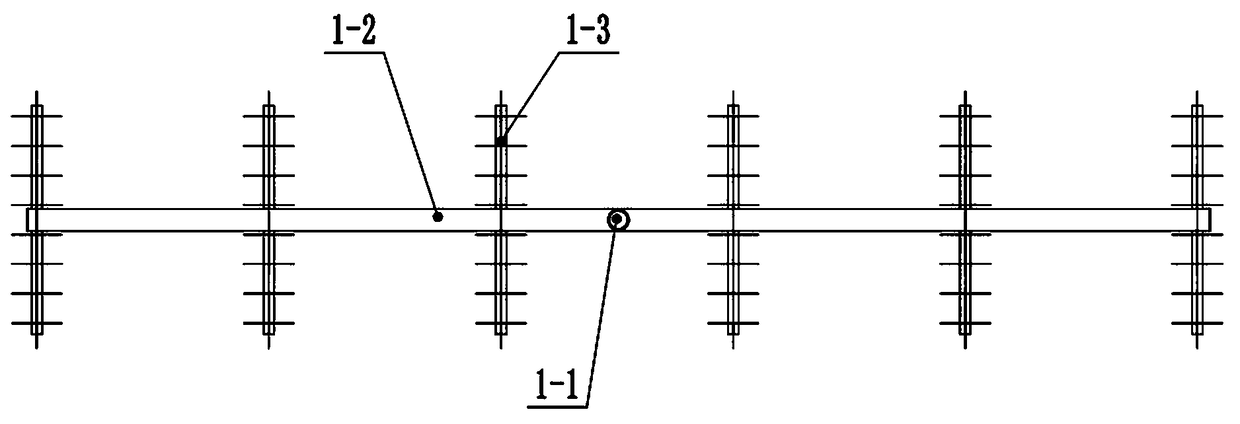

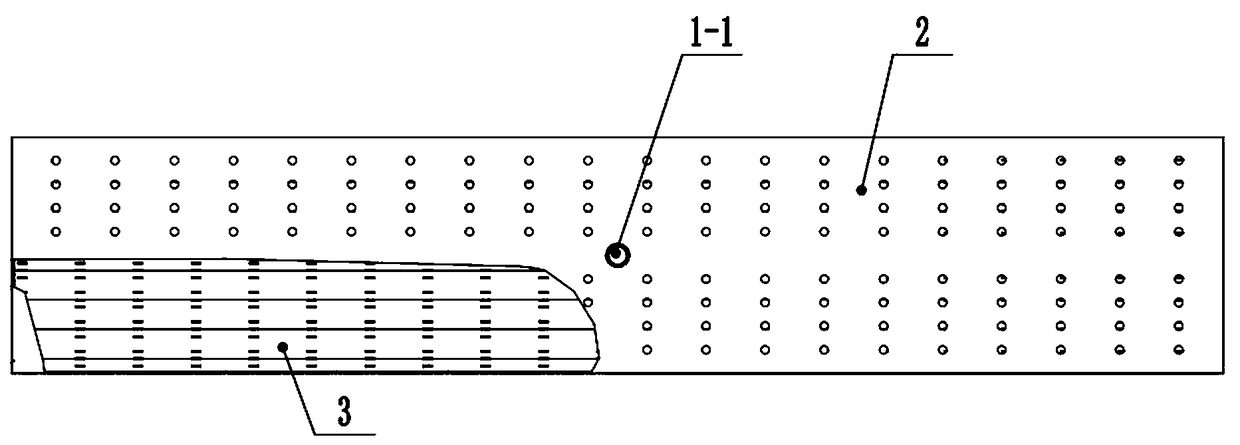

[0025] Such as Figures 1 to 3 , an ammonia liquid distributor, comprising a liquid pipe 1 and a box-shaped body, the body is arranged horizontally, the top plate is a gas equalizing plate 2, and the bottom plate is a liquid separating plate 3;

[0026] The liquid-dispensing pipe 1 includes a standpipe 1-1, a manifold 1-2 and several branch pipes 1-3, the manifold 1-2 and the branch pipes 1-3 are arranged in the inner cavity of the body, and each branch pipe 1-3 is respectively It communicates with the header 1-2; preferably, the header 1-2 is arranged in the main body in a front-to-back direction, and each branch pipe 1-3 is arranged in a left-right direction, respectively arranged on the left and right sides of the header 1-2.

[0027] There is an upper liquid separation hole on the branch pipe 1-3; there is a certain vertical distance between the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com