High-salinity comprehensive wastewater treatment system for chemical industry parks

A comprehensive wastewater and treatment system technology, applied in the direction of oxidized water/sewage treatment, multi-stage water treatment, water/sewage treatment, etc., can solve the problems of front-end electrodialysis membrane pollution, evaporation efficiency decline, etc., to facilitate subsequent biochemical treatment, The effect of reducing COD concentration in wastewater

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

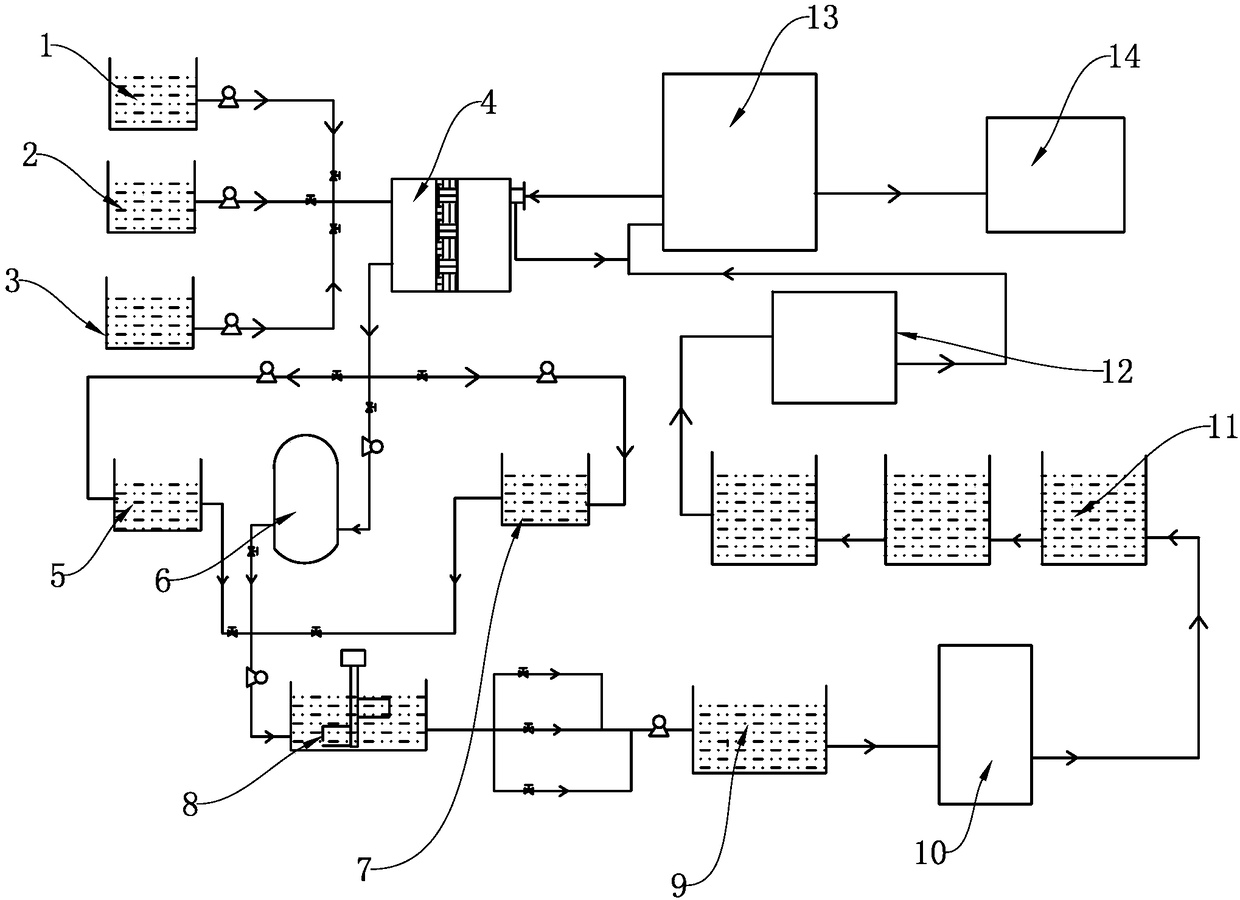

[0024] A high-salt comprehensive wastewater treatment system in a chemical industry park, such as figure 1 As shown, it includes classification storage unit, forward osmosis treatment unit (forward osmosis treatment device), pretreatment unit, coagulation sedimentation unit (coagulation sedimentation tank), adjustment tank unit (regulation tank), medium temperature anaerobic unit (medium temperature ABR reaction device), an aerobic reaction unit, and a desalination unit; the classified storage units are three disconnected acidic organic wastewater storage pools 1, alkaline organic wastewater storage pool 2, and biochemical organic wastewater storage pool 3, and the pretreatment unit includes micro The electrolytic reaction pool 5, the ozone oxidation tower 6, the SBR pool 7, the desalination unit includes an ultrafiltration device, a reverse osmosis device and an evaporation device; the wastewater outlet of the acidic organic wastewater storage tank 1 is connected to the forwar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com