Method of cutting thin slices and suppressing scratches

A thin slice and cutting technology, applied in coating, metal processing, etc., can solve the problem of increased water absorption of thin slices, and achieve the effect of suppressing scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

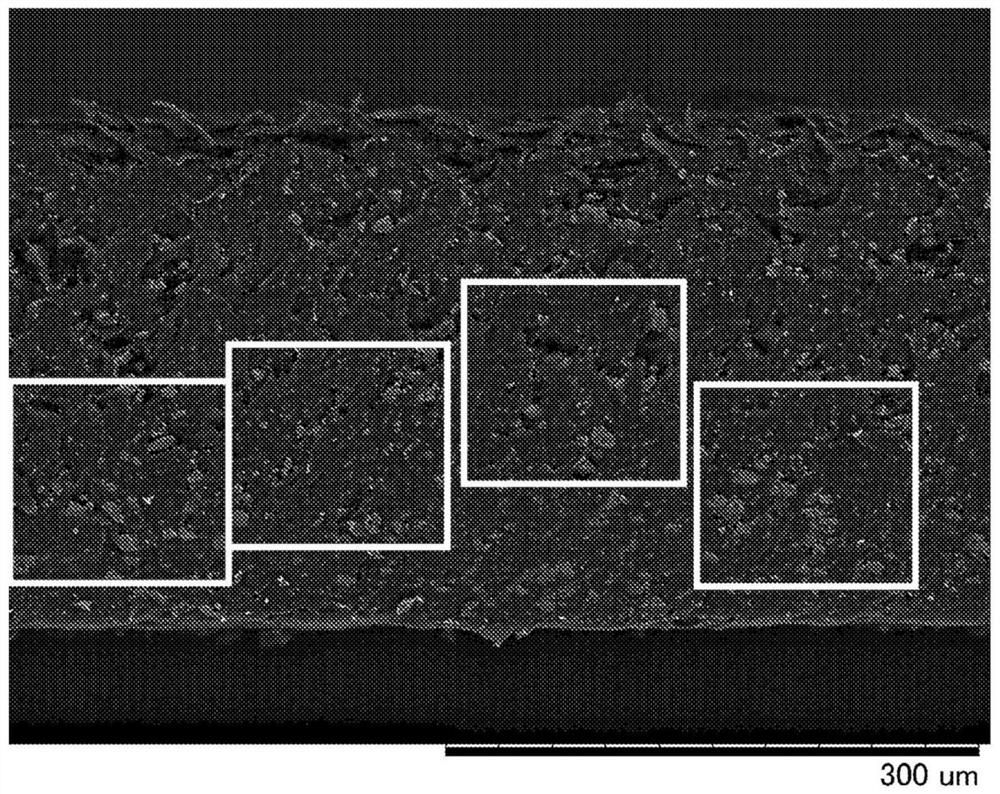

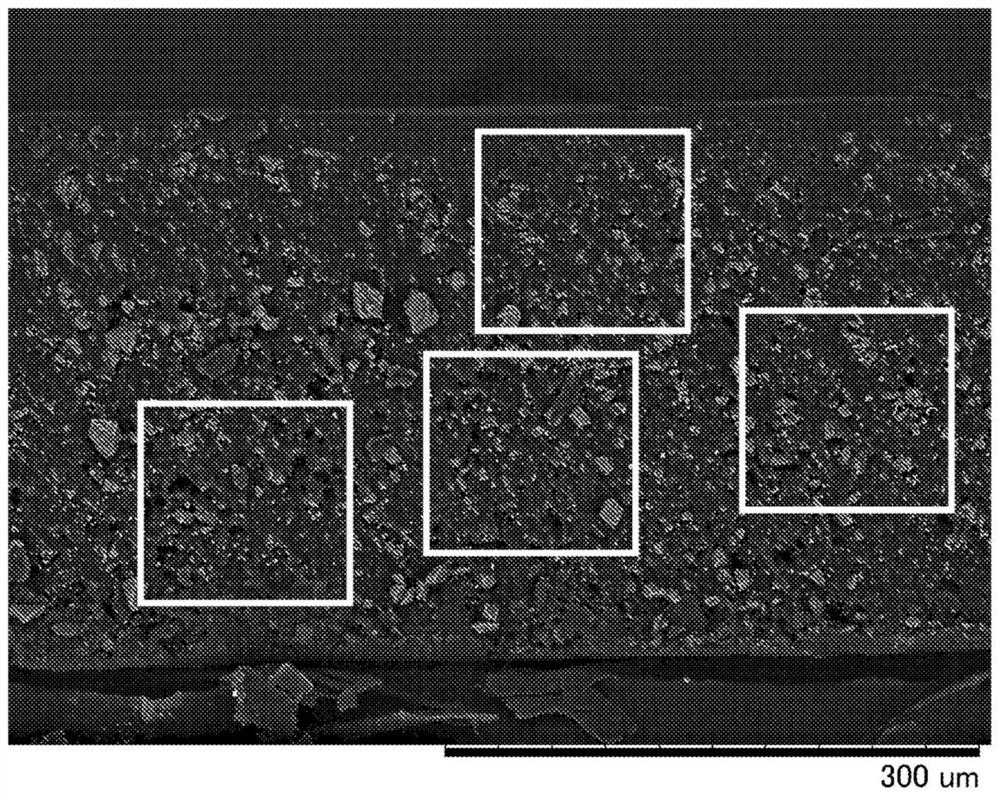

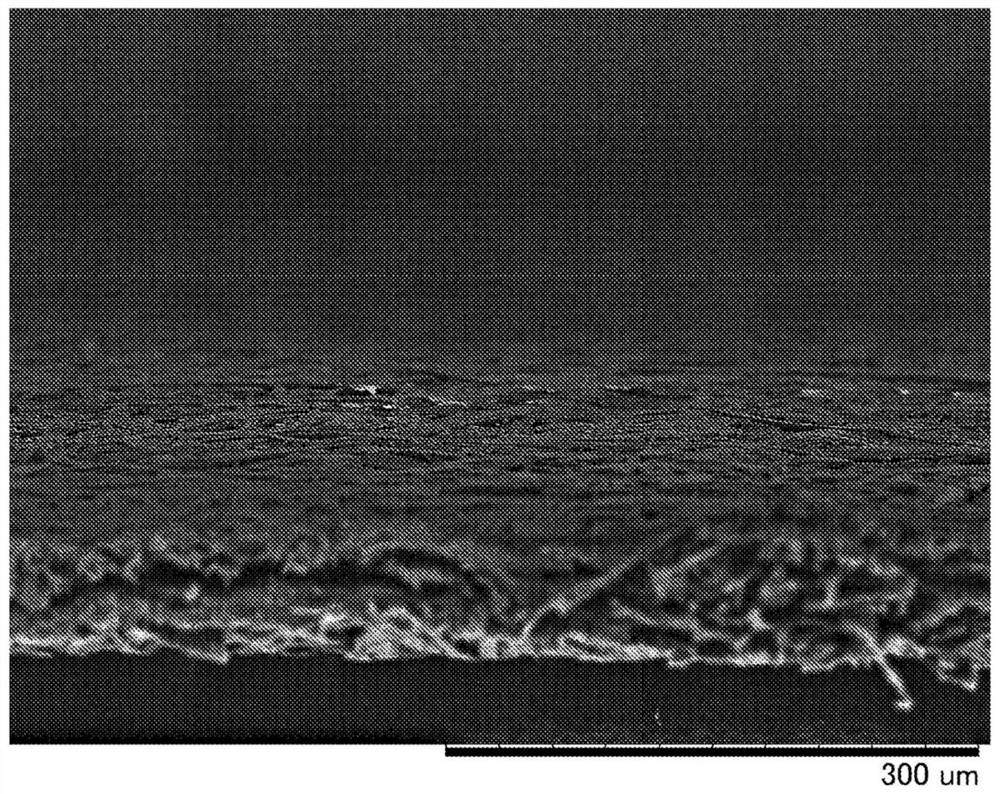

Image

Examples

Embodiment 1

[0074] Utilize a biaxial kneading extruder to make the polypropylene resin containing 40% by mass (density 0.91 [g / cm 3 ]), heavy calcium carbonate (average particle diameter 5 μ m) 60 mass % main component, and the resin composition (the content of calcium carbonate in the resin composition is 0.5 mass % antistatic agent added with respect to main component 59.7% by mass, polypropylene resin 39.8% by mass) and then stretched 1.5 times with a longitudinal stretcher to produce a sheet, which was then cut with a desktop cutter.

Embodiment 2

[0076] The polyurethane resin was coated on the front and back of the sheet produced in Example 1 with a micro gravure coater, and cut with a table cutter.

Embodiment 3

[0078] The acrylic resin was coated on the front and back of the sheet produced in Example 1 with a micro gravure coater, and cut with a table cutter.

[0079] [Evaluation 1]

[0080] The physical properties (density, basis weight, thickness, breaking point strength, breaking point elongation, tear strength, gloss, whiteness, opacity, water absorption) of the cut sheets produced by Examples 1 to 3 ) for evaluation. The results are shown in Table 1. Density conforms to JIS K7112, basis weight conforms to JIS P8124, thickness conforms to JIS K7130, breaking point strength and breaking point elongation conforms to JIS K7162, tear strength conforms to JIS K7128-3, glossiness conforms to JISP8142, and whiteness conforms to According to JIS P8148, opacity is a value measured according to JIS P8149. The water absorption rate is a value calculated by immersing in pure water for 24 hours according to JIS K7209, taking it out from the water, wiping off the water lightly with a cloth,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com