A rotating stage and control method for multi-station precision operation

A rotating stage and multi-station technology, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, generators/motors, etc. Affect the movement and positioning accuracy, and the processing accuracy is extremely high, so as to achieve the effect of improving output performance, convenient control, and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

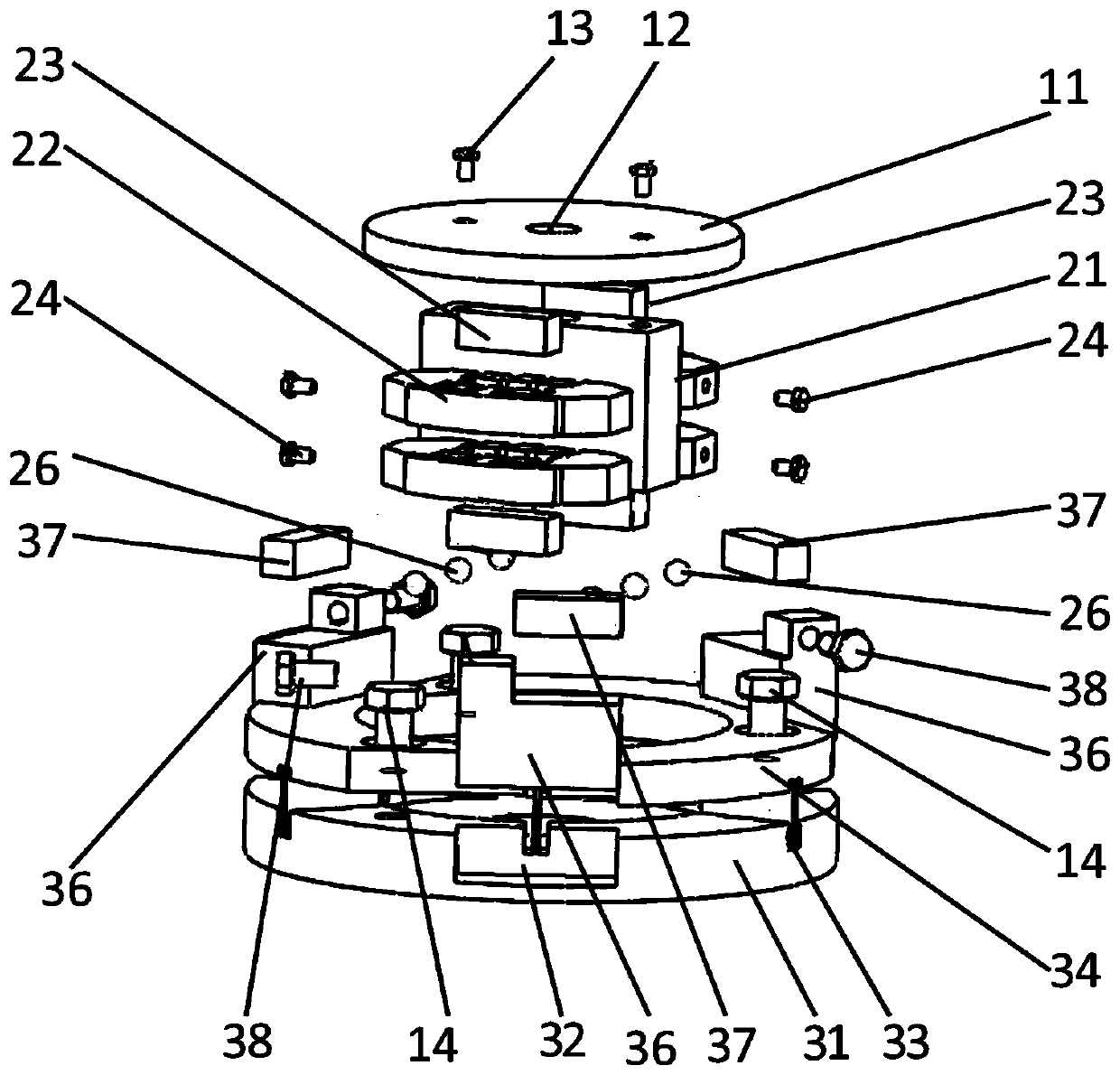

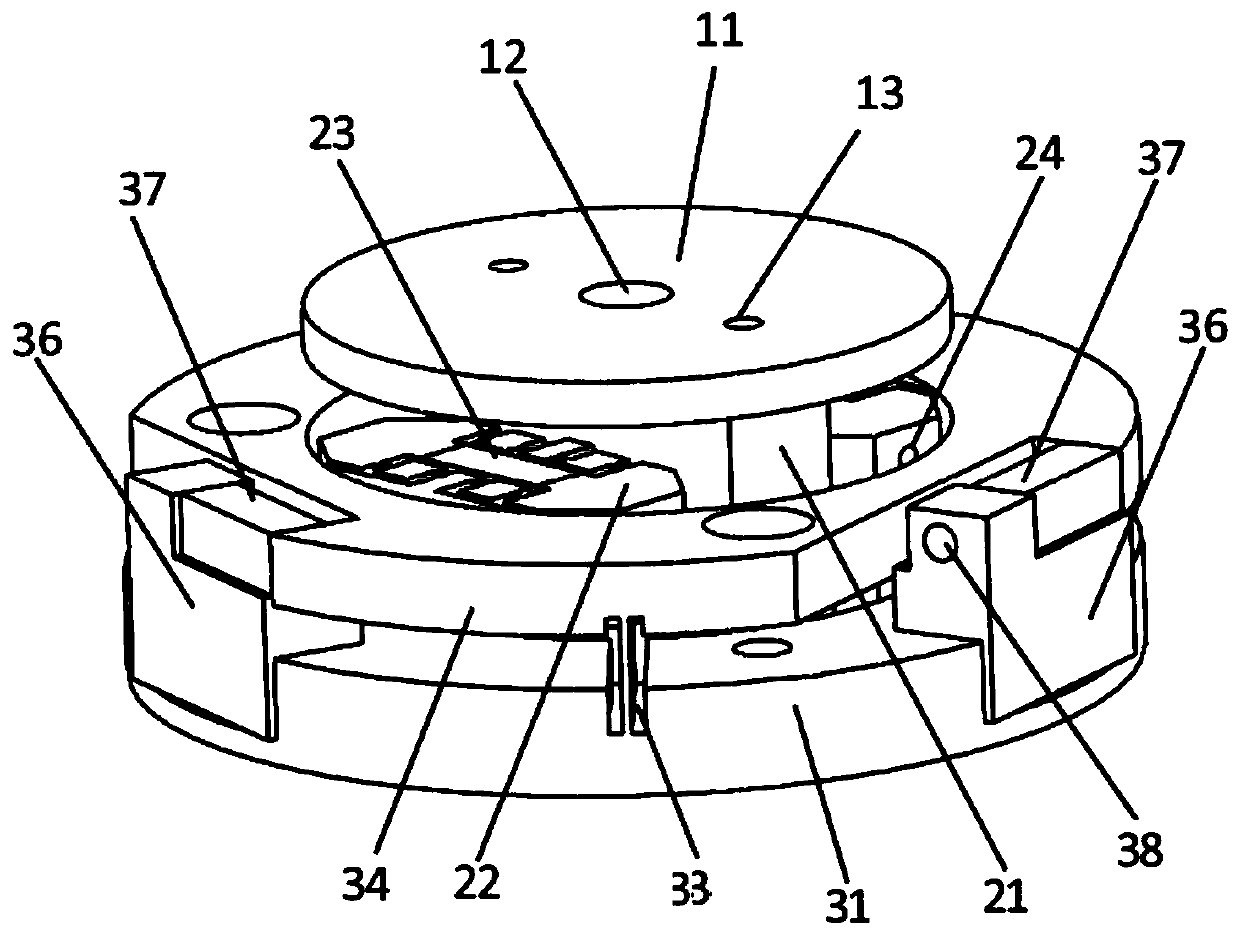

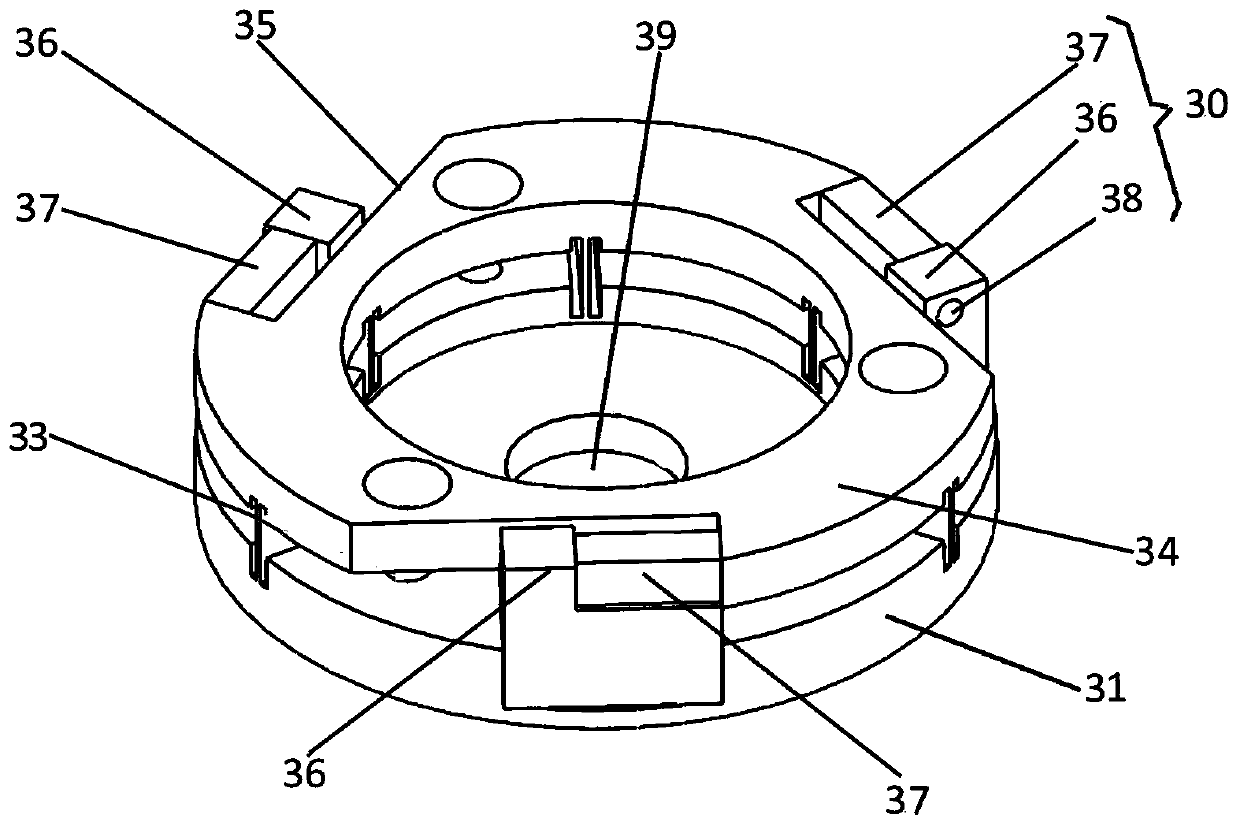

[0038] Refer to attached Figures 1 to 9 The rotary stage and control method for multi-station precision operation of the present invention are described in detail.

[0039]The rotary stage and control method for multi-station precision operation of the present invention belong to the field of precision operation, can be applied to the rotation positioning of multi-station precision operation, and can be used for precision optics, precision machining, micromanipulation, micro-clamping, Micromechanical performance testing and other fields. The rotating stage includes: a fixing mechanism, a moving mechanism and a loading plane 11 . The moving mechanism is assembled in the fixing mechanism through a clearance fit, and the fixing mechanism is provided with a plurality of piezoelectric stack drive units 30, and the plurality of piezoelectric stack driving units 30 generate axial displacement after being energized to drive the moving mechanism For rotation, the loading plane 11 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com