Raw material sand drying device for concrete production

A technology for sand drying and concrete, which is applied in drying, dryers, heating devices, etc., can solve the problems of uneven drying of raw sand and low drying efficiency, achieve thorough drying, improve drying quality, Increase the effect of agitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

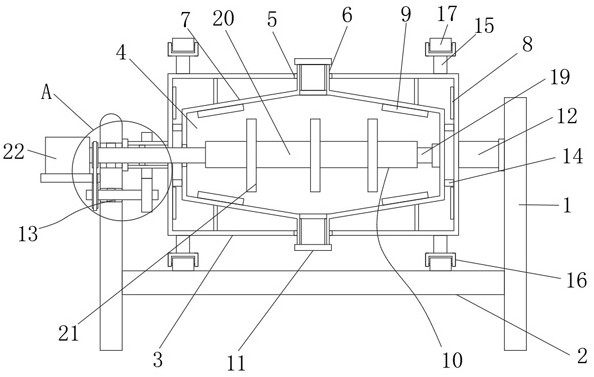

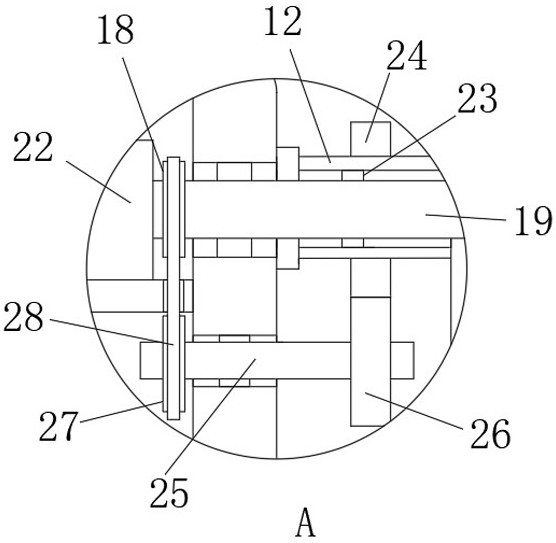

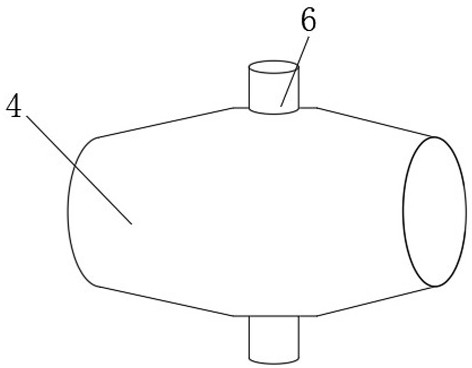

[0022] Embodiment one, by Figure 1 to Figure 3 Given, the present invention includes two support plates 1, the two support plates 1 are connected by a connecting plate 2, an outer cylinder 3 is arranged above the connecting plate 2, an inner cylinder 4 is connected to the inside of the outer cylinder 3, and the outer cylinder 3 Heating plates 8 are symmetrically arranged on both sides of the inner wall of the inner cylinder 4, and heating blocks 9 are symmetrically arranged on both sides of the inner wall of the inner cylinder 4. Through the design of the heating block 9 and the heating plate 8, the inside of the inner cylinder 4 can be heated, and the two sides of the outer cylinder 3 The opening 5 is symmetrically opened in the middle position of the side, and the material tube 6 penetrating through the opening 5 is symmetrically provided on both sides of the inner cylinder 4. The inside of the material tube 6 is provided with a sealing tube 11, and the inside of the inner c...

Embodiment 2

[0023] Embodiment two, on the basis of embodiment one, by figure 1 Given, the pulley assembly includes a support rod 15, a mounting seat 16 and a roller 17, the support rod 15 is equidistantly fixedly mounted on the outer wall of the outer cylinder 3, one end of the support rod 15 is provided with a mounting seat 16, and a roller is installed on the mounting seat 16 17. Improve the support of the outer cylinder 3 and facilitate the flexible rotation of the outer cylinder 3.

Embodiment 3

[0024] Embodiment three, on the basis of embodiment one, by figure 1 Given, the stirring mechanism 10 includes a rotating shaft 19, a stirring drum 20 and a stirring plate 21, one end of the rotating shaft 19 is installed on the inner wall of the inner cylinder 4, and the other end of the rotating shaft 19 runs through the inner cylinder 4, the outer cylinder 3 and the rotating shaft in sequence 12 and extends to the support plate 1, the rotating shaft 19 is covered with a mixing drum 20 located inside the inner cylinder 4, and the outer wall of the mixing drum 20 is equidistantly provided with stirring plates 21, thereby realizing the stirring of the raw sand.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com