Coaxial connector of cable

A coaxial connector and cable technology, which is applied in the direction of connection, two-part connection device, and parts of the connection device, can solve the problems of mutual interference of high-frequency signals, many extension structures, and large standing waves. The effect of increasing connection reliability, simple terminal structure, and reducing thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

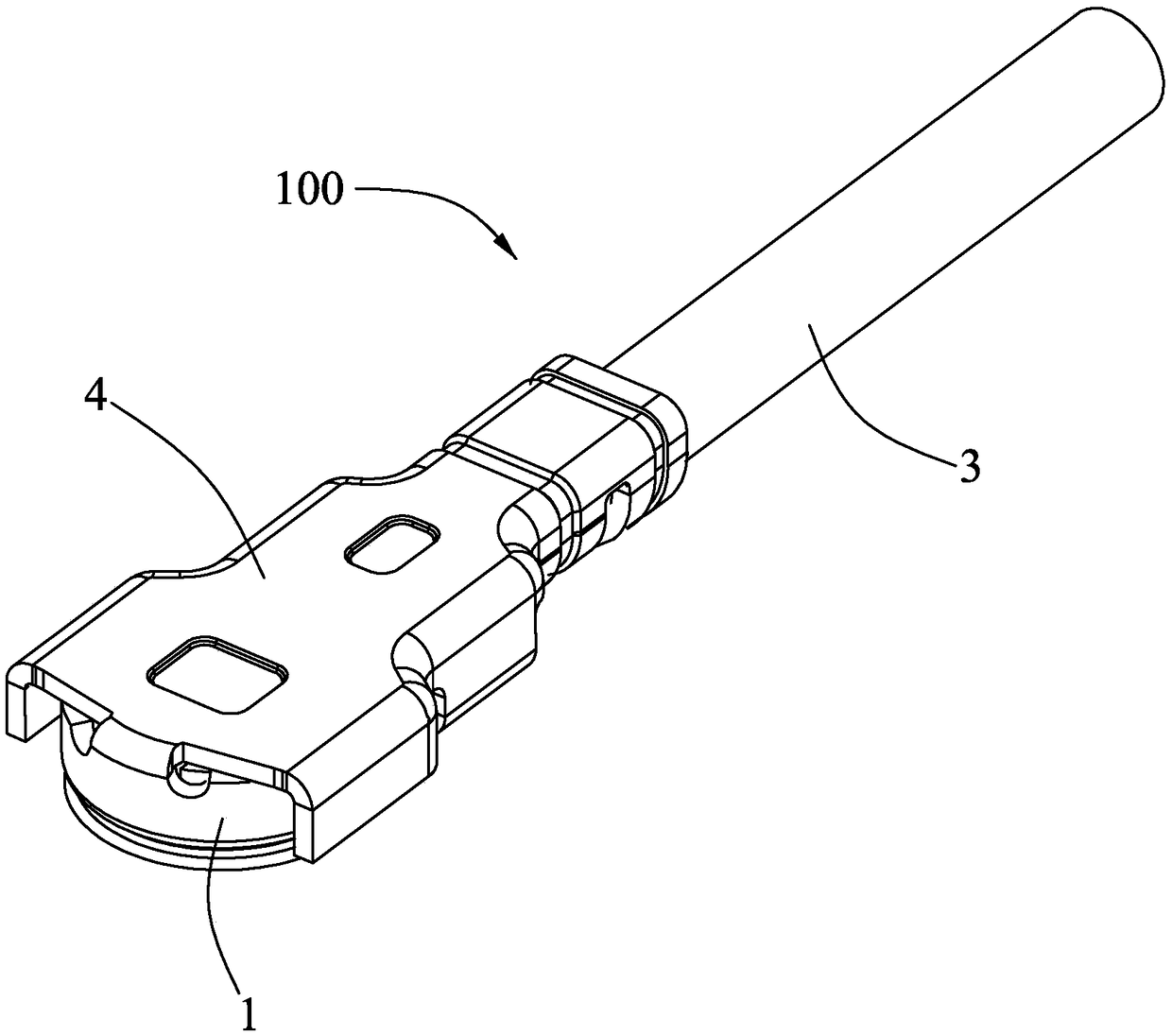

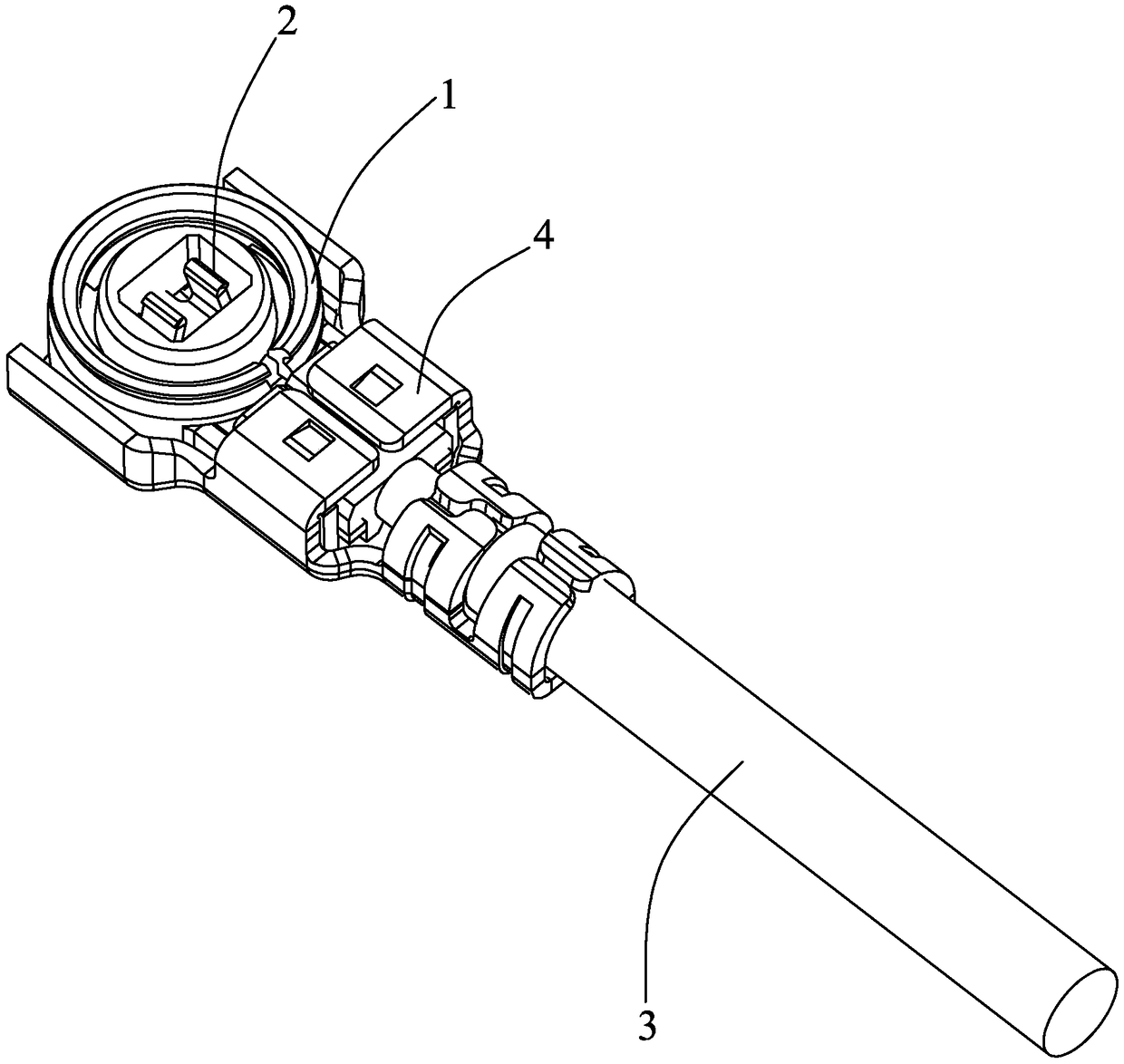

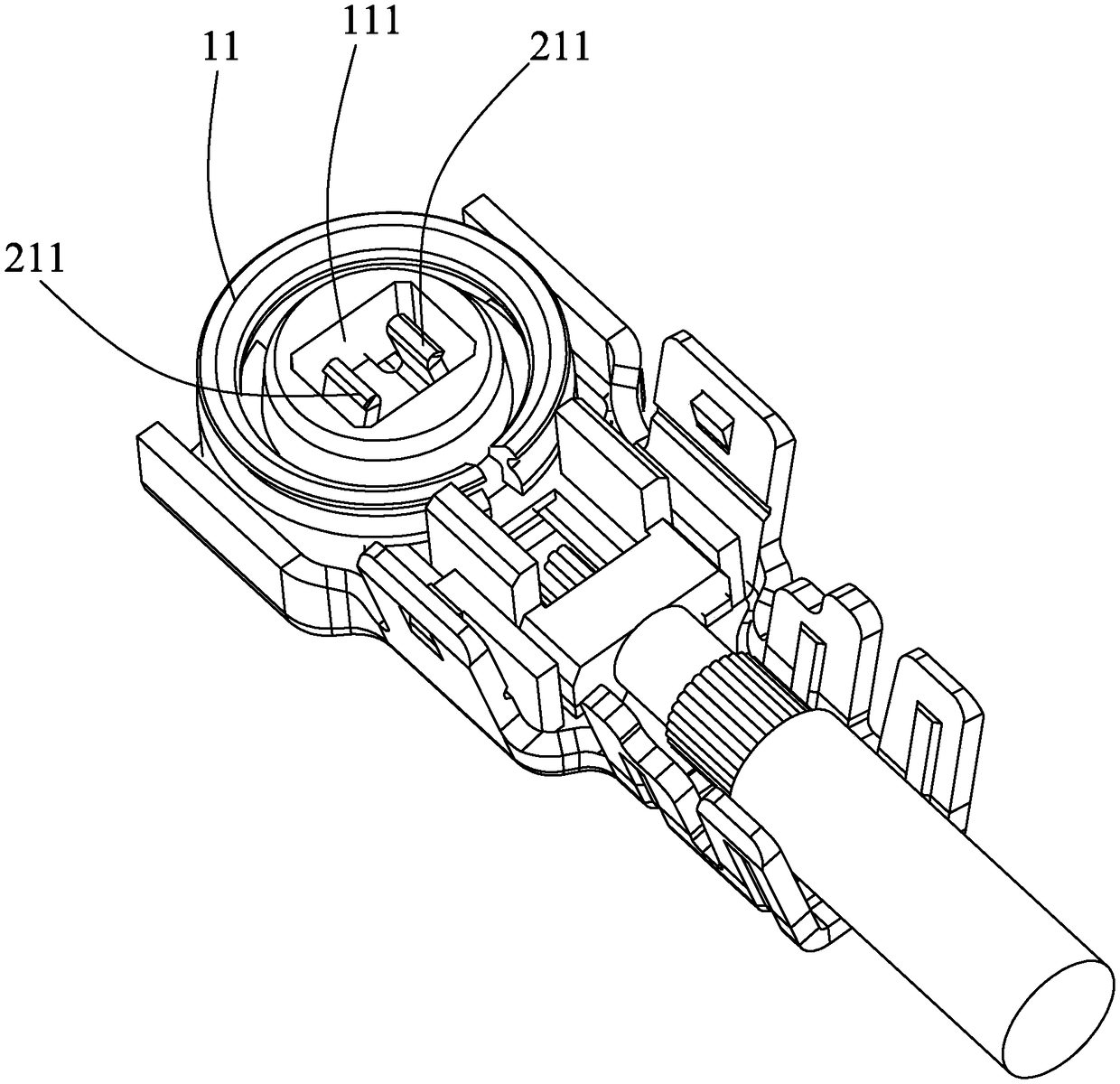

[0035] Such as Figure 1 to Figure 11 As shown, a cable coaxial connector 100 includes: an insulating body 1 , a conductive terminal 2 fixed to the insulating body 1 , a cable 3 connected to the conductive terminal 2 , and a metal shell 4 covering the insulating body 1 .

[0036] The insulating body 1 includes a cylindrical portion 11 , a rotatable cover 12 extending upward from a front end of the cylindrical portion 11 , and an extension portion 13 extending backward from a rear end of the cylindrical portion 11 . The cylindrical part 11 is provided with a slot 111 for inserting a mating connector, and the extension part 13 is provided with a receiving groove 131 for receiving the cable 3 . The slot 111 is located on the lower side of the insulating body 1 , the receiving groove 131 is located on the upper side of the insulating body 1 , and the insul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com