A new type of cast iron electric hob

A technology of cast iron pans and electric hobs, which is applied in the direction of household stoves/stoves, electric heating fuel, lighting and heating equipment, etc., can solve problems such as assembly troubles, achieve the effects of reducing assembly difficulty, simplifying terminal structure, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

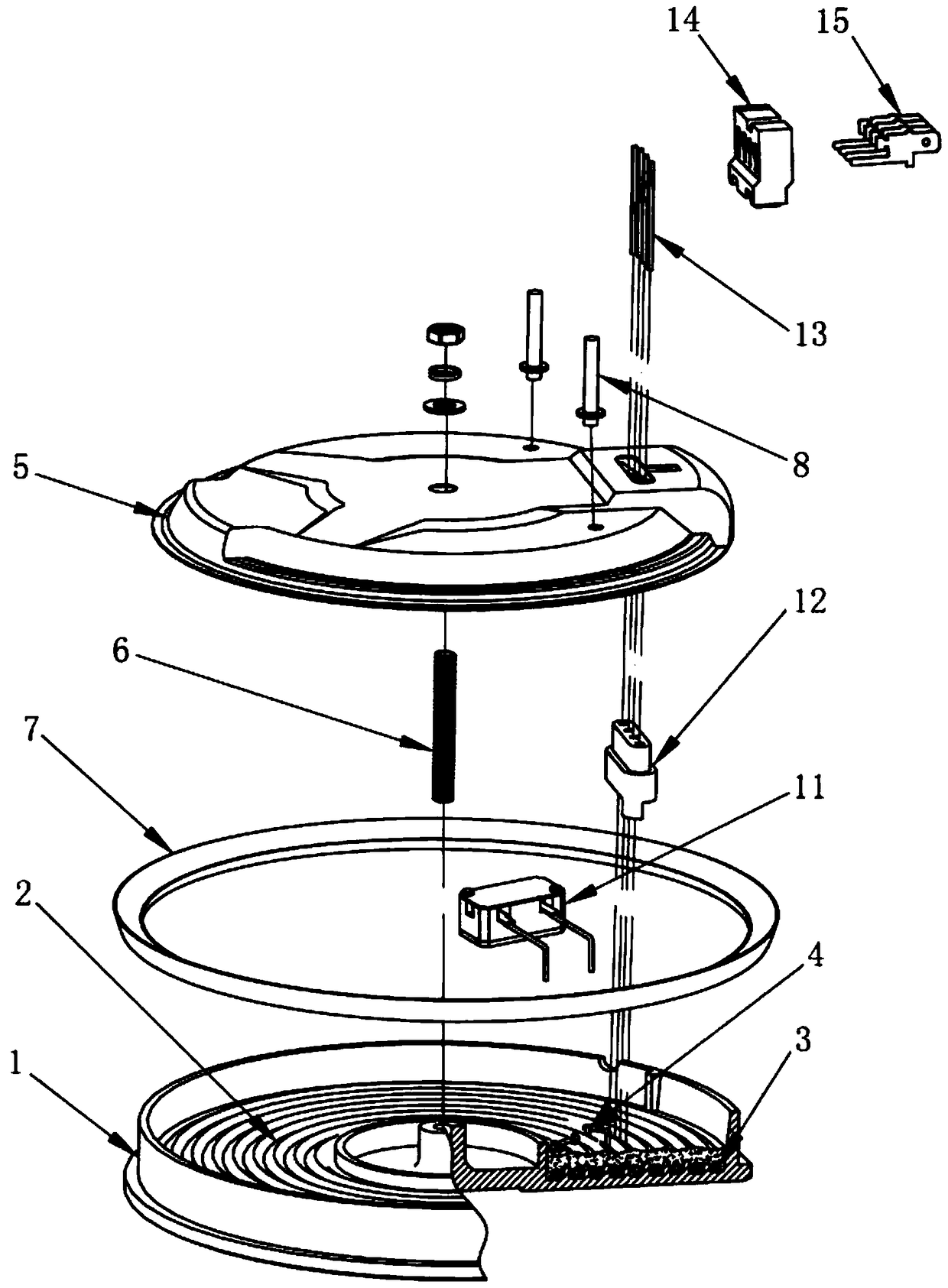

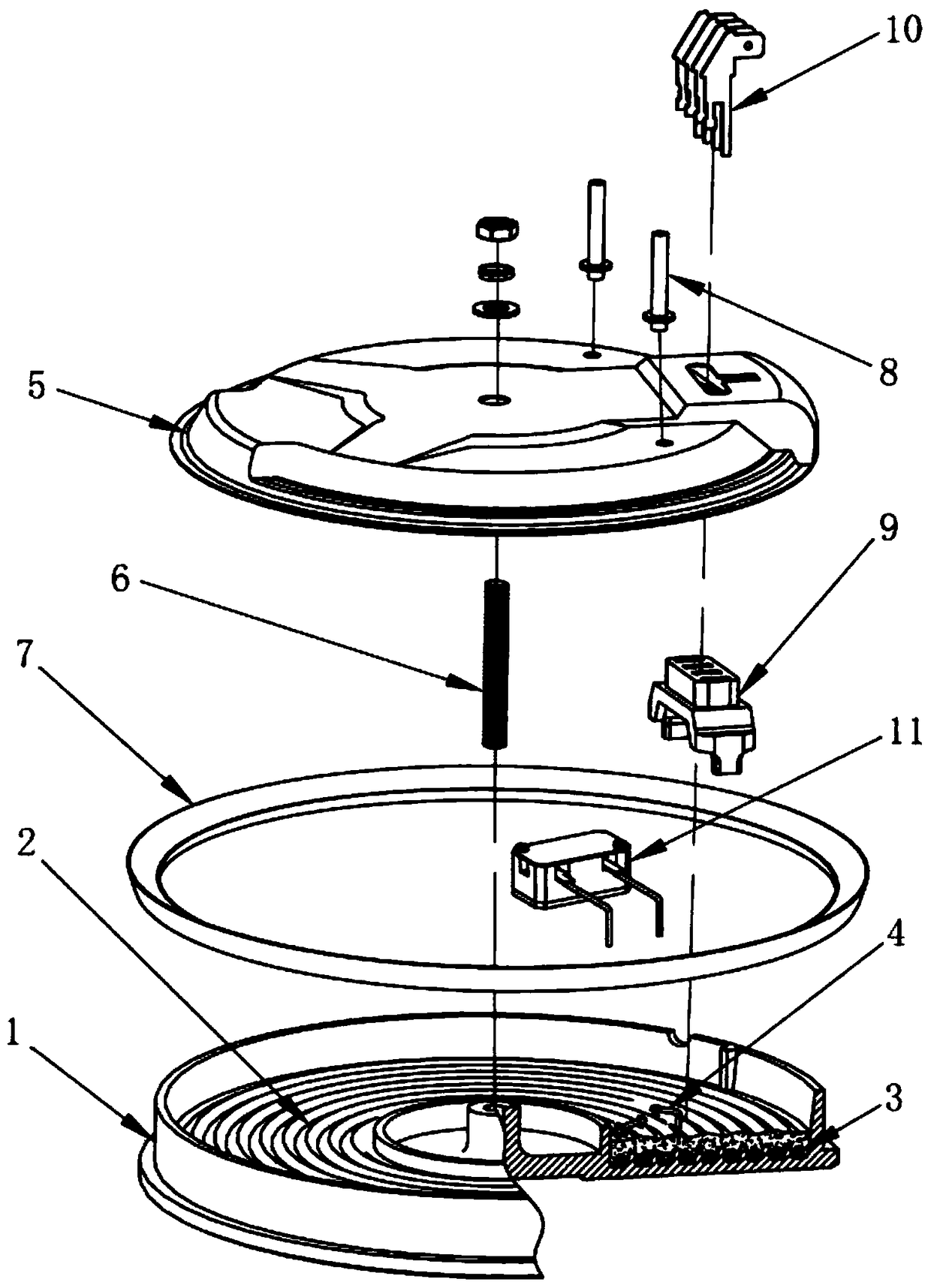

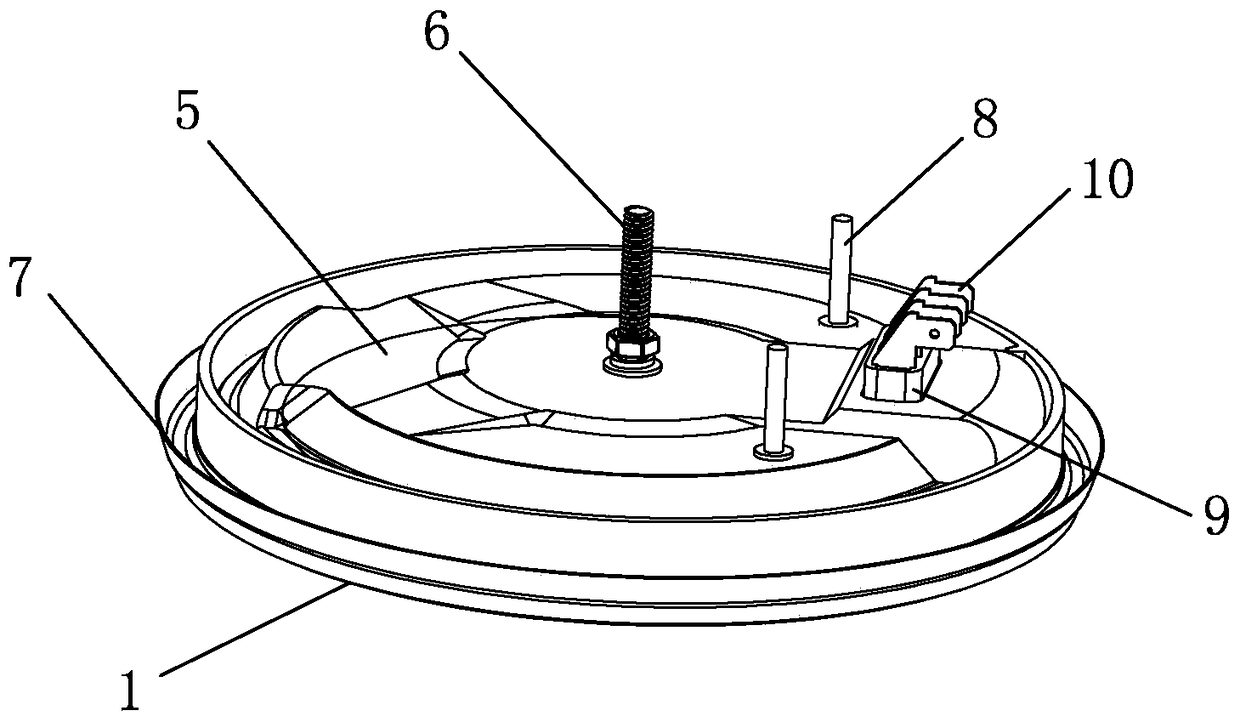

[0020] refer to figure 2 , image 3 , the first embodiment provided by the present invention is a new type of cast iron electric hob, including a shell composed of a cast iron plate surface 1 and a heat shield 5 covering the cast iron plate surface 1, a heating wire 2 is arranged inside the shell, and the heating wire 2 is installed close to the surface of the cast iron plate 1, the heating wire 2 is covered with an insulating layer 3, and the lead wire 4 of the heating wire 2 is arranged on the insulating layer 3. The shell is provided with an embedded ceramic base 9 fixed by welding, the lower port of the embedded ceramic base 9 is connected with the lead wire 4, and the upper port of the embedded ceramic base 9 passes through the heat shield 5 upwards, and embedded The upper port of the type porcelain seat 9 is equipped with a curved horizontal insert 10. Further, a temperature controller 11 is also arranged in the housing.

[0021] The heat shield 5 is installed and po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com