Special compact type anti-loose gear

A compact, anti-loosening technology, applied in the direction of belts/chains/gears, components with teeth, portable lifting devices, etc., can solve the problems of high production and use costs, complex assembly, single function, etc., and achieve high assembly efficiency , The use of accuracy is guaranteed, safe and reliable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

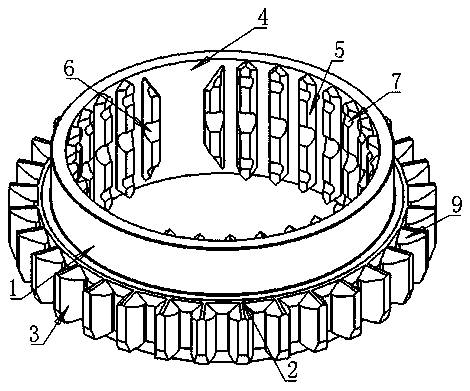

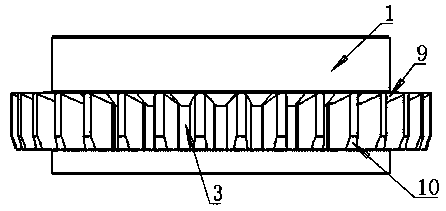

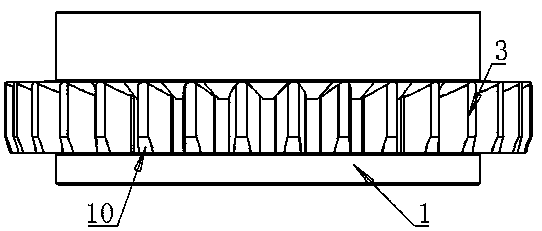

[0018] like Figure 1 to Figure 8 As shown, a special compact anti-loosening gear, which integrates the gear structure and the connecting fastener structure, makes the gear structure not only have the function of engaging the gear, but also has a better function of connecting the fastener. The position of the internal snap-fit assembly teeth is also provided with anti-loosening groove structures of different sizes, which makes it more convenient to assemble, better to connect, more stable during use, and more reliable in safety. The position of the snap-fit assembly teeth of the parts is respectively provided with a convenient assembly structure for easy assembly, which makes the assembly efficiency of the parts in the assembly process higher, the assembly accuracy more reliable, and the use accuracy in the use process is more guaranteed. An assembly positioning groove is also provided at the position of the internal teeth of the assembly assembly, so that the internal pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com