Special simple type lubricating connecting fastener

A simple and fastening technology, applied in the direction of engine lubrication, fixing devices, engine components, etc., can solve the problems of high production and use costs, complex assembly, single function, etc., and achieve the effect of good tightness, stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

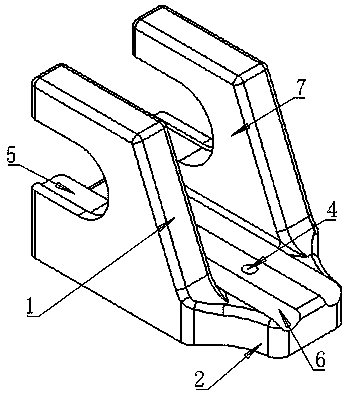

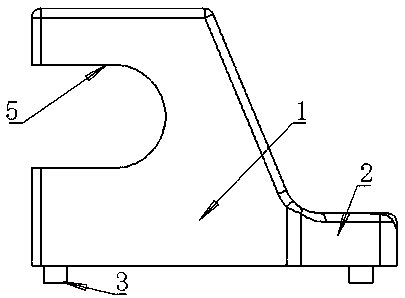

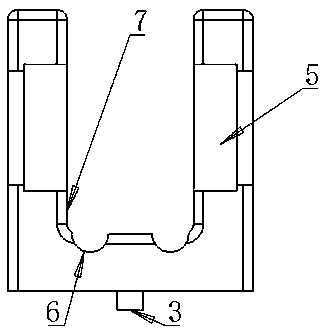

[0017] Such as Figure 1 to Figure 6 As shown, a special simple lubricating connection fixture, which combines the lubricating structure and the connecting fastener, and sets the corresponding sealing groove to make the sealing performance of the lubricating structure better when connecting and assembling. The effect is better when lubricating. In addition, the connecting fasteners are connected and assembled with the mechanical equipment through a snap-fit connection, which is more convenient during assembly, and the connection is tighter, and can be better assembled and connected with the mechanical equipment. Together, after the assembly is completed, it also has a good anti-loosening effect, making it more stable during assembly, so that the safety of mechanical equipment during use is higher, and the overall production and use costs are lower. . It includes a main body fixed connection structure 1 whose main body shape is a right-angled trapezoid. An integrally formed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com