Maintenance method and device of diesel SCR aftertreatment system

A technology of SCR system and diesel engine, which is applied in the electronic control of exhaust treatment device, diagnostic device of exhaust treatment device, exhaust treatment, etc., and can solve the problems that it is difficult to reach the emission target.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

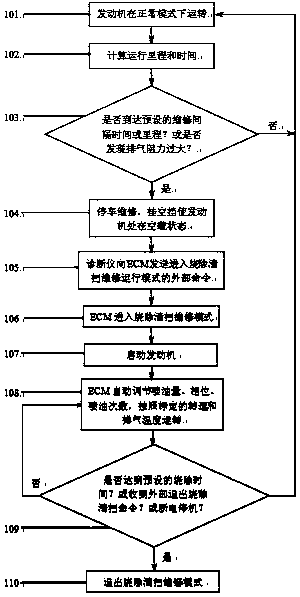

[0035] exist figure 1 The flow of the invention shown figure 1 In the above, it is assumed that the original ECM of the engine has the function of switching the operating mode through an external command, that is, switching between the normal mode and the burning, cleaning and maintenance mode. External commands can be generated by the diagnostic tool.

[0036] Under normal circumstances, the engine runs in normal mode (step 101). In step 102, the cumulative running mileage and time since the last burning and cleaning maintenance are calculated. According to the vehicle calibration results, there is a preset next maintenance mileage or time interval. In step 103, it is necessary to judge whether the mileage or time calculated in step 102 has reached the preset interval (for example, 20,000 kilometers or 6 months of use), and it is also judged whether the power of the engine is reduced due to excessive exhaust resistance when the engine is running , if the judgment result of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com