Vacuum plating sterilization film

A technology of vacuum plating and sterilization layer, applied in vacuum evaporation plating, sputtering plating, ion implantation plating, etc., can solve the problems of low efficiency, strong dependence, side effects of organic sterilization materials, etc., and achieve a wide range of sterilization, The sterilization speed is fast and the effect of increasing the sterilization range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

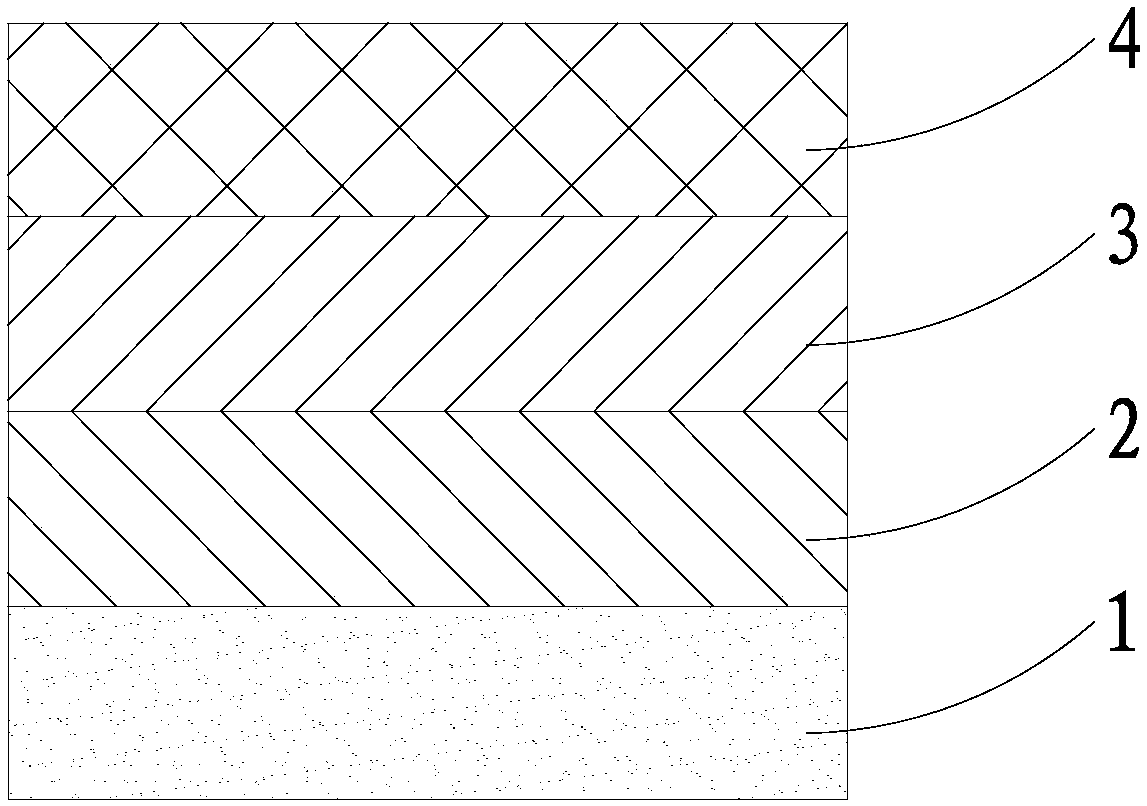

[0026] like figure 1 As shown, the manufacturing method of the vacuum plating bactericidal film includes the following steps: adopting the method of ion plating to deposit Ti on the stainless steel substrate as a spacer layer, the thickness of the spacer layer is 0.1 μm, and then using the method of magnetron sputtering to deposit BiCuSe 3 Deposited on the spacer layer as a bactericidal layer, the thickness of the bactericidal layer is 20nm, and finally, Al is deposited on the bactericidal layer as a protective layer by magnetron sputtering, and the thickness of the protective layer is 0.1 μm.

[0027] Preparation of the spacer layer: the method of ion plating is adopted, and the Ti film is deposited by multi-arc ion plating. After the sample is cleaned by Ar ion sputtering in the coating chamber for 5 minutes, Ti is deposited. The target material is a titanium dioxide target with a purity of 99.99%. The target chamber is vacuum Degree 3.2×10 -1 Pa. The coating process param...

Embodiment 2

[0035] like figure 1 As shown, the manufacturing method of the vacuum plating bactericidal film includes the following steps: adopting the method of ion plating to deposit Ni on the aluminum alloy substrate as a spacer layer, the thickness of the spacer layer is 0.5 μm, and then use the method of magnetron sputtering to deposit BiAgSe 3 Deposited on the spacer layer as a bactericidal layer, the thickness of the bactericidal layer is 200nm, and finally Ni is deposited on the bactericidal layer as a protective layer by magnetron sputtering, and the thickness of the protective layer is 0.5 μm.

[0036] Preparation of bactericidal layer: BiAgSe 3 Prepared by magnetron sputtering, the target material for magnetron sputtering is BiAgSe 3, with a purity of 99.99%. In the experiment, Ar gas was used as the sputtering gas, and an appropriate amount of oxygen was introduced, and the sputtering was carried out after the current and voltage were fully stabilized. During sputtering, the...

Embodiment 3

[0043] Such as figure 1 As shown, the manufacturing method of the vacuum plating bactericidal film includes the following steps: adopt the method of ion plating to deposit Al on the copper substrate as a spacer layer, the thickness of the spacer layer is 1 μm, and then use the method of magnetron sputtering to deposit the BiAgSe 3 Deposit on the spacer layer as a bactericidal layer, the thickness of the bactericidal layer is 500nm, and finally deposit Ti on the bactericidal layer as a protective layer by magnetron sputtering, the thickness of the protective layer is 1 μm.

[0044] Preparation of bactericidal layer: BiAgSe 3 Prepared by magnetron sputtering, the target material for magnetron sputtering is BiAgSe 3 , with a purity of 99.99%. In the experiment, Ar gas was used as the sputtering gas, and an appropriate amount of oxygen was introduced, and the sputtering was carried out after the current and voltage were fully stabilized. During sputtering, the working pressure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com