Preparation method of anti-bacteria cotton fabric containing AgO/TiO2 composite

A composite antibacterial and antibacterial cotton technology, which is applied in plant fibers, textiles, papermaking, fiber treatment, etc., can solve the problems of weak antibacterial ability, low sterilization speed, and high preparation cost, and achieve strong antibacterial activity, fast sterilization speed, and low price Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

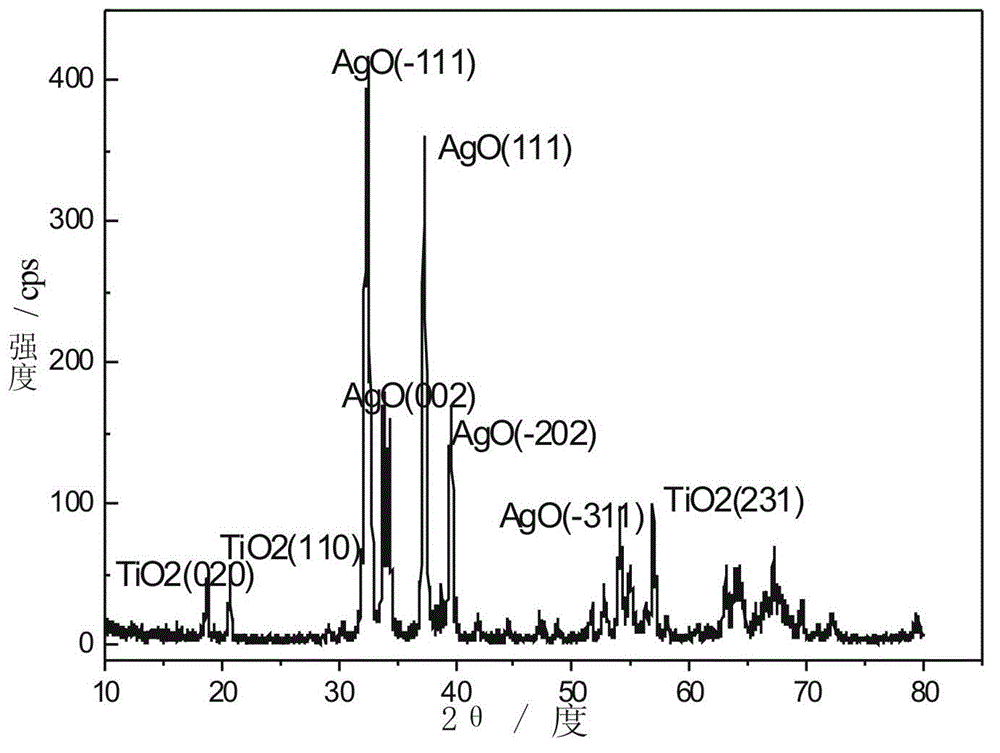

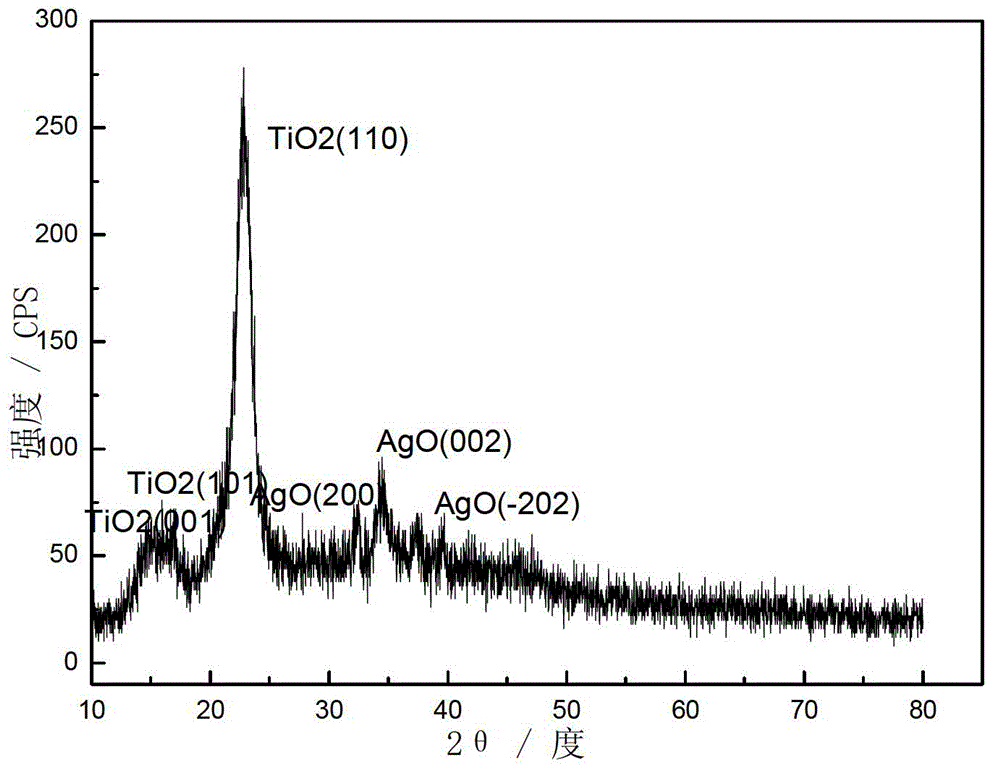

[0026] The invention provides an AgO / TiO-containing 2 The preparation method of composite antibacterial cotton fabric is characterized in that, implements according to the following steps:

[0027] step 1,

[0028] Weigh AgO powder and TiO according to the mass ratio of 3:2 2 Put the powder into the ball mill after mixing, the speed of the ball mill is 2000r / min, rotate clockwise, take it out after ball milling for 4 hours, and obtain ultrafine AgO / TiO 2 Composite antibacterial powder; the particle size distribution of AgO powder is between 0.286μm-9.437μm, the median diameter is 2.88μm, TiO 2 The particle size distribution of the powder is between 0.286 μm and 13.10 μm, and the median diameter is 3.39 μm.

[0029] Step 2,

[0030] Weigh polyvinylpyrrolidone as a surfactant and place it in the reactor, add deionized water to make the surfactant concentration 1.5g / L, then place the mixed liquid in a constant temperature water bath and heat to 35°C, and stir for 10min Make ...

Embodiment 1

[0034] Weigh AgO powder and TiO according to the mass ratio of 3:2 2 Put the powder into the ball mill after mixing, the speed of the ball mill is 2000r / min, rotate clockwise, take it out after ball milling for 4 hours, and obtain ultrafine AgO / TiO 2 Composite antibacterial powder; the particle size distribution of AgO powder is between 0.286μm-9.437μm, the median diameter is 2.88μm, TiO 2 The particle size distribution of the powder is between 0.286 μm and 13.10 μm, and the median diameter is 3.39 μm.

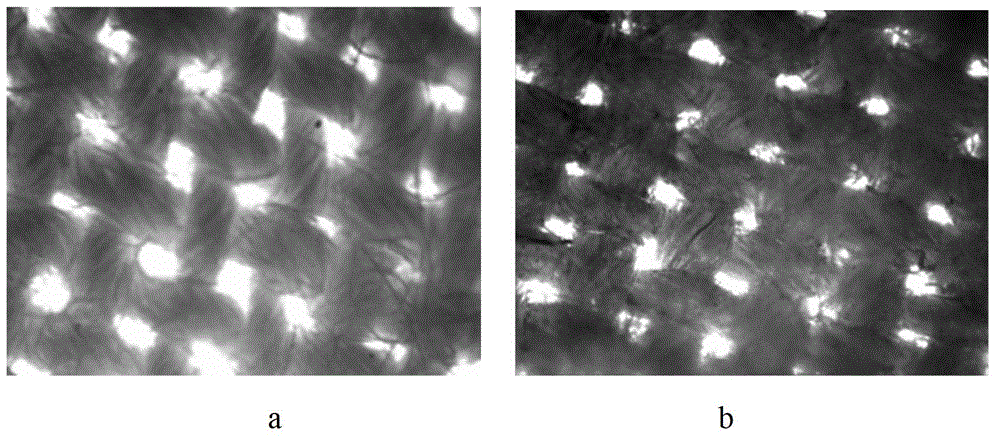

[0035] Weigh polyvinylpyrrolidone as a surfactant and place it in the reactor, add deionized water to make the surfactant concentration 1.5g / L, then place the mixed liquid in a constant temperature water bath and heat to 35°C, and stir for 10min Make it dissolve, then add the ultrafine AgO / TiO prepared in step 1 2 Composite antibacterial powder, making ultrafine AgO / TiO 2The composite antibacterial powder accounted for 2% of the mass fraction of the mixed liquid, and contin...

Embodiment 2

[0037] Weigh AgO powder and TiO according to the mass ratio of 3:2 2 Put the powder into the ball mill after mixing, the speed of the ball mill is 2000r / min, rotate clockwise, take it out after ball milling for 4 hours, and obtain ultrafine AgO / TiO 2 Composite antibacterial powder; the particle size distribution of AgO powder is between 0.286μm-9.437μm, the median diameter is 2.88μm, TiO 2 The particle size distribution of the powder is between 0.286 μm and 13.10 μm, and the median diameter is 3.39 μm. Weigh polyvinylpyrrolidone as a surfactant and place it in the reactor, add deionized water to make the surfactant concentration 1.5g / L, then place the mixed liquid in a constant temperature water bath and heat to 35°C, and stir for 10min Make it dissolve, then add the ultrafine AgO / TiO prepared in step 1 2 Composite antibacterial powder, making ultrafine AgO / TiO 2 The composite antibacterial powder accounted for 2.5% of the mass fraction of the mixed liquid, and continued to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Median diameter | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com