Double-resisting one-side release material

A release material, single-sided technology, applied in the direction of coating, film/sheet release liner, adhesive, etc., can solve the problems of harshness, unstable performance, poor weather resistance, etc., to reduce transfer rate and improve coating Elongation and uniformity, and the effect of improving weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

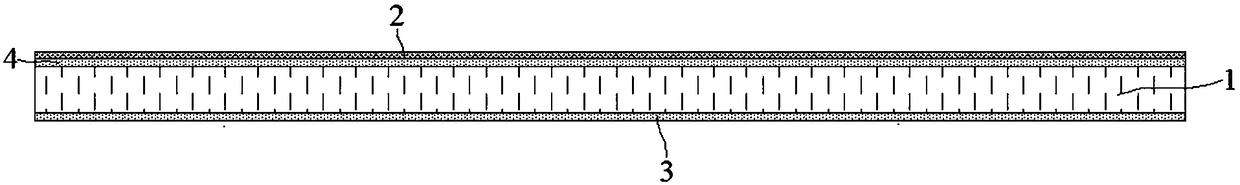

[0025] Embodiment 1: A double anti-single-sided release material, including a base film layer 1, a release agent layer 2 coated on the upper surface of the base film layer 1 and an antistatic coating coated on the lower surface of the base film layer 1 3. The thickness of the release agent layer 2 is 0.3 μm, and the release agent layer 2 is obtained by curing the release agent, and the release agent is obtained from the following components by weight:

[0026] 100 parts of pre-polymerized resin,

[0027] 0.85 parts of methyl hydroquinone,

[0028] 35 parts of 3-propylene oxide,

[0029] 15 parts of dodecyl glycidyl ether,

[0030] 3.2 parts of 1-hydroxycyclohexyl benzophenone.

[0031] Described prepolymerized resin is obtained by following steps:

[0032] Step 1, put 32 parts of cyclohexyl methacrylate, 25 parts of β-carboxyethyl acrylate, and 9 parts of acrylic acid into a mixing tank, and stir at a low speed to form a primary mixture;

[0033] Step 2, mix the primary m...

Embodiment 2

[0039] Embodiment 2: A double anti-single-sided release material, including a base film layer 1, a release agent layer 2 coated on the upper surface of the base film layer 1 and an antistatic coating coated on the lower surface of the base film layer 1 3. The thickness of the release agent layer 2 is 0.1-0.7 μm, and the release agent layer 2 is obtained by curing the release agent, and the release agent is obtained from the following components by weight:

[0040] 100 parts of pre-polymerized resin,

[0041] 0.9 parts of methyl hydroquinone,

[0042] 30 parts of 3-propylene oxide,

[0043] 18 parts of dodecyl glycidyl ether,

[0044] 4.5 parts of 1-hydroxycyclohexyl benzophenone.

[0045] Described prepolymerized resin is obtained by following steps:

[0046] Step 1. Put 45 parts of cyclohexyl methacrylate, 28 parts of β-carboxyethyl acrylate, and 11 parts of acrylic acid into a mixing tank, and stir at a low speed to form a primary mixture;

[0047] Step 2, mix the prima...

Embodiment 3

[0053] Embodiment 3: A double anti-single-sided release material, including a base film layer 1, a release agent layer 2 coated on the upper surface of the base film layer 1 and an antistatic coating coated on the lower surface of the base film layer 1 Layer 3, the thickness of the release agent layer 2 is 0.3 μm, the release agent layer 2 is obtained by curing the release agent, and the release agent is obtained from the following components by weight:

[0054] 100 parts of pre-polymerized resin,

[0055] 1 part methyl hydroquinone,

[0056] 28 parts of 3-propylene oxide,

[0057] 12 parts of dodecyl glycidyl ether,

[0058] 3.5 parts of 1-hydroxycyclohexyl benzophenone.

[0059] Described prepolymerized resin is obtained by following steps:

[0060] Step 1. Put 38 parts of cyclohexyl methacrylate, 22 parts of β-carboxyethyl acrylate, and 10 parts of acrylic acid into a mixing tank, and stir at a low speed to form a primary mixture;

[0061] Step 2, mix the primary mixtu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com