A kind of organic fluorosilicon release type emulsion with good stability and preparation method thereof

A technology with stable performance and organic fluorine, applied in the field of organofluorosilicon release emulsion and its preparation, can solve the problems of unstable anchoring, increased storage cost, increased process and cost, etc. Storage stability, the effect of wide distribution of fluorine groups

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A kind of organofluorine silicone release emulsion with good stability performance, it is composed of: 5 parts of alkenyl polyfluorosiloxane, 1.95 parts of hydrogen-containing polyfluorosiloxane, phenyl hydroxyl network silicone resin 0.05 parts, 3 parts of adhesion aid, 5 parts of surfactant, 85 parts of water.

[0050] The alkenyl polyfluorosiloxane is polytrifluoro-MDT resin with vinyl-terminated network structure, and its viscosity is 100 mPa·s.

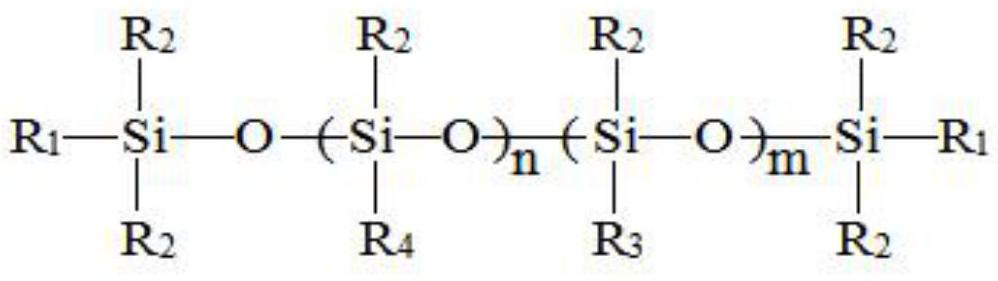

[0051] The structural formula of the hydrogen-containing polyfluorosiloxane is as follows:

[0052]

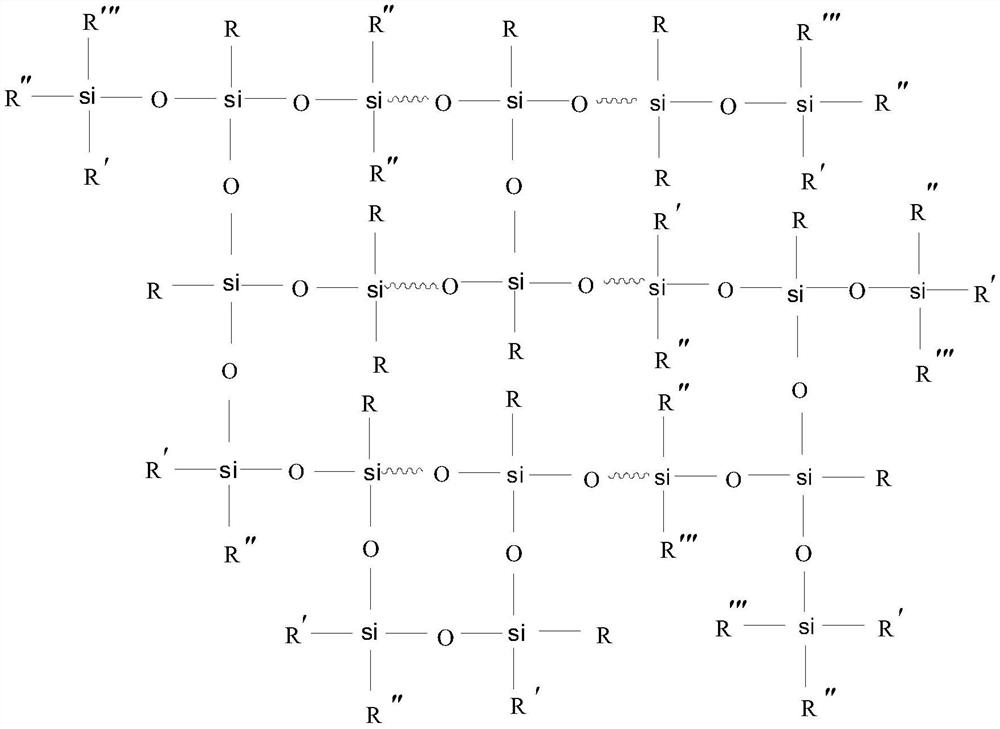

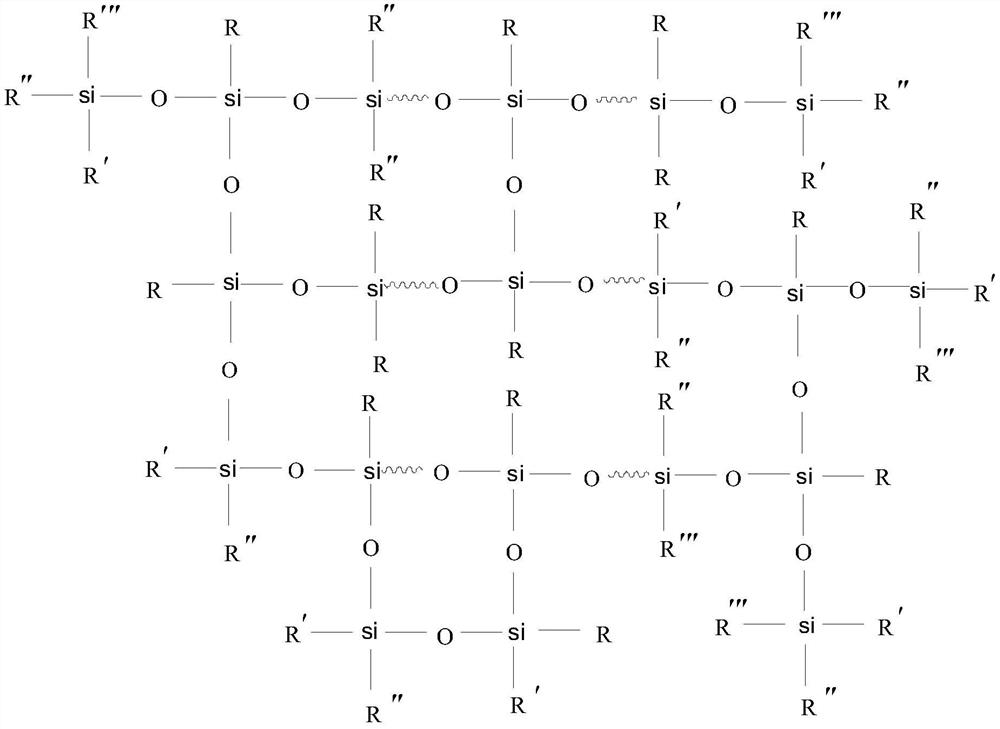

[0053] The structural formula of the phenyl hydroxy reticular silicone resin is as follows:

[0054]

[0055] Wherein, R, R", R"' are the same or different straight-chain or branched aryl groups of 6-20 carbon atoms or aralkyl groups of 7-20 carbon atoms; R' is a hydroxyl group.

[0056] The preparation method of the phenylhydroxy reticular silicone resin is as follows: respectively add 140 g of distilled water and...

Embodiment 2

[0065] An organic fluorosilicon release emulsion with good stability, which consists of: 15 parts of alkenyl polyfluorosiloxane, 0.5 part of hydrogen-containing polyfluorosiloxane, phenyl hydroxy network silicone resin 1 part, 3.5 parts of adhesion aid, 10 parts of surfactant, 70 parts of water.

[0066] The alkenyl polyfluorosiloxane is polytrifluoro MDQ resin with vinyl-terminated network structure, and its viscosity is 700 mPa·s.

[0067] The structural formula of the hydrogen-containing polyfluorosiloxane is as follows:

[0068]

[0069] The structural formula of the phenyl hydroxy reticular silicone resin is as follows:

[0070]

[0071] Wherein, R, R", R"' are the same or different straight-chain or branched aryl groups of 6-20 carbon atoms or aralkyl groups of 7-20 carbon atoms; R' is a hydroxyl group.

[0072] The preparation method of the phenyl hydroxy reticular silicone resin is as follows: respectively add 200 g of distilled water and 1.2 g of hydrochloric ...

Embodiment 3

[0081] An organic fluorosilicon release emulsion with good stability, which consists of 25 parts by weight of alkenyl polyfluorosiloxane, 7.9 parts of hydrogen-containing polyfluorosiloxane, phenyl hydroxy network silicone resin 1 part, 0.1 part of adhesion aid, 1 part of surfactant, 65 parts of water.

[0082] The alkenyl polyfluorosiloxane is polyheptafluoride MTQ resin with a vinyl-terminated network structure, and its viscosity is 500 mPa·s.

[0083] The hydrogen-containing polyfluorosiloxane structural formula is as follows:

[0084]

[0085] The structural formula of the phenyl hydroxy reticular silicone resin is as follows:

[0086]

[0087] Wherein, R, R", R"' are the same or different straight-chain or branched aryl groups of 6-20 carbon atoms or aralkyl groups of 7-20 carbon atoms; R' is a hydroxyl group.

[0088] The preparation method of the phenyl hydroxy reticular silicone resin is as follows: respectively add 200 g of distilled water and 1.2 g of hydroch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com