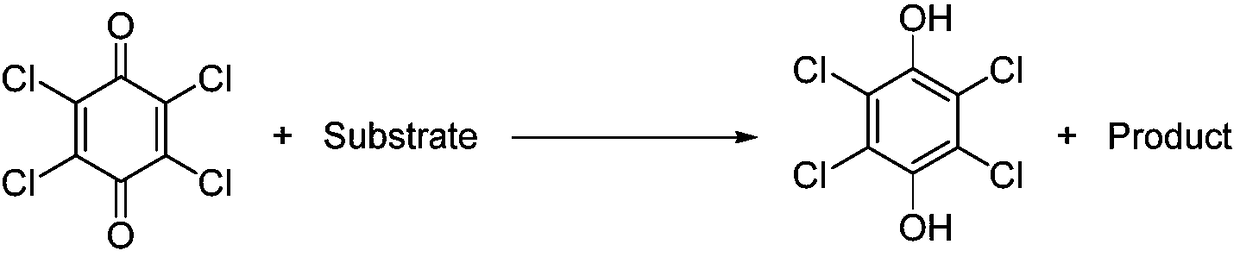

Method for regenerating chloranil by oxidation of hydrogen peroxide

A technology of hydrogen peroxide and chlorobenzoquinone, which is applied in the field of compound preparation, can solve the problems of difficult recycling of solvents, waste of resources, and high equipment requirements, and achieve the effects of improving chemical synthesis methods, reducing waste of resources, and protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

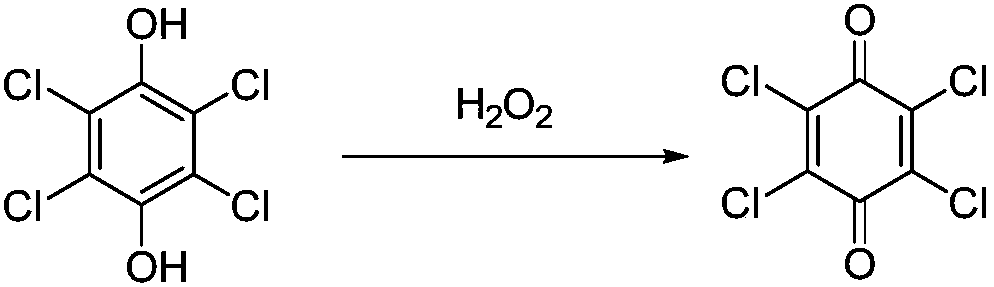

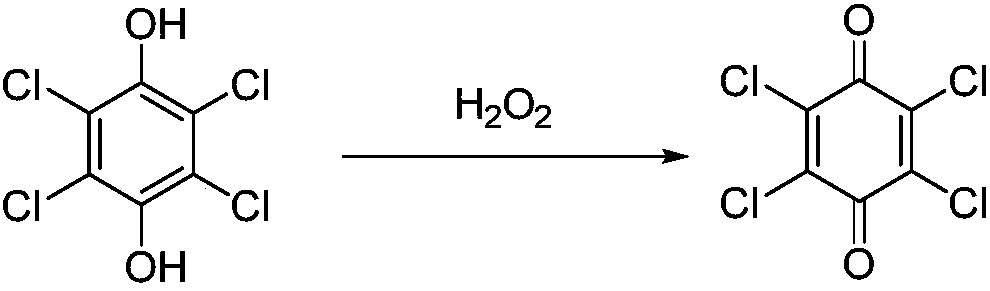

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: A kind of method of hydrogen peroxide oxidation regeneration chloranil

[0022] Add 6ml methyl alcohol in test tube, the tetrachlorohydroquinone of 496mg (2.0mmol), the hydrogen peroxide (hydrogen peroxide mass fraction is 30%, containing 2.0mmol hydrogen peroxide) of 227mg, stir reaction at room temperature for 5 days, stop reaction, only A very small amount of solid product chloranil was observed, and the product was obtained by filtration with a yield of 10%.

Embodiment 2

[0023] Embodiment 2: A kind of method of hydrogen peroxide oxidation regeneration chloranil

[0024] In test tube, add 6ml methanol, 496mg (2.0mmol) of tetrachlorohydroquinone, 454mg of hydrogen peroxide (hydrogen peroxide mass fraction is 30%, containing 4.0mmol hydrogen peroxide), stirred and reacted at room temperature for 5 days, stopped the reaction, and The reaction solution was filtered to obtain the product with a yield of 27%.

Embodiment 3

[0025] Embodiment 3: A kind of method of hydrogen peroxide oxidation regeneration chloranil

[0026] In test tube, add 6ml methanol, 496mg (2.0mmol) of tetrachlorohydroquinone, 908mg of hydrogen peroxide (the mass fraction of hydrogen peroxide is 30%, containing 8.0mmol hydrogen peroxide), stirred and reacted at room temperature for 5 days, stopped the reaction, and The reaction solution was filtered to obtain the product with a yield of 39%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com