Plastering mortar for exterior wall external insulation of phenolic aldehyde foam board, and preparation method thereof

A technology for phenolic foam board and external wall thermal insulation, which is applied in the field of plastering mortar materials, can solve the problems of low alkalinity, cracking and bonding, and not firmness of plastering mortar, and achieves fast coagulation and hardening, offset dry shrinkage, and good coordination. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The concrete preparation method of above-mentioned plastering mortar comprises the steps:

[0032] First, take each component according to the proportioning ratio;

[0033] Second, the sulphoaluminate cement and quartz sand are stirred evenly;

[0034] Third, pour zeolite powder, cellulose ether, rubber powder, bentonite and short fibers into the mixer in turn to stir and mix evenly;

[0035] Fourth, packaging and storage.

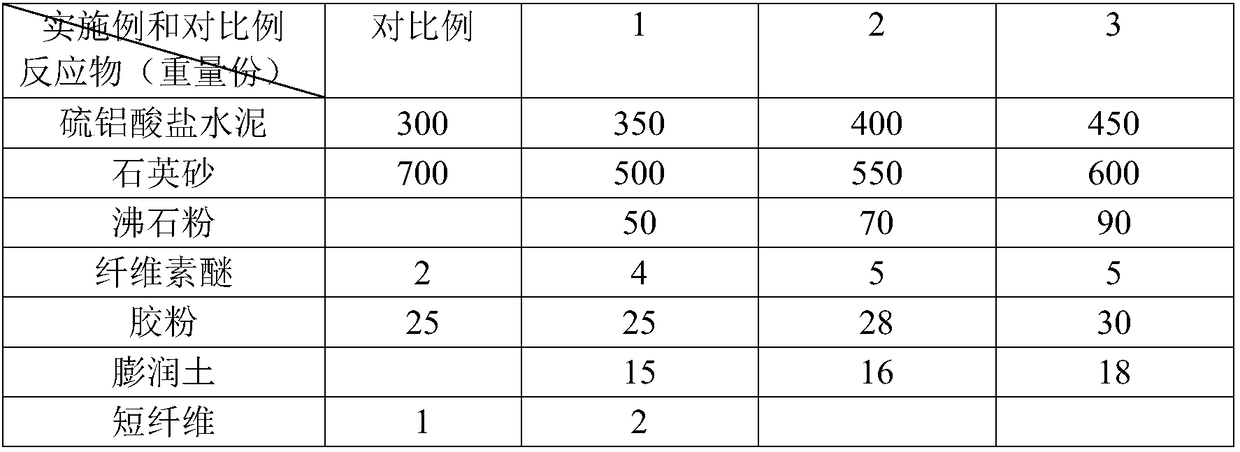

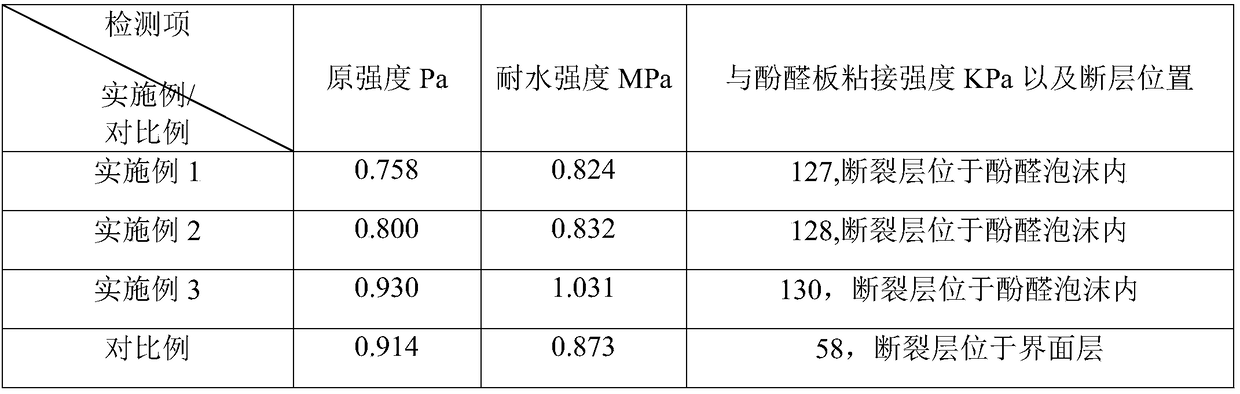

[0036] Examples 1-3 were obtained according to the above-mentioned preparation method, and the selection of specific reactants in the examples is shown in Table 1 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com