Automatic counting winding and cutting machine and braid winding and cutting method

A technology of automatic counting and roll cutting machine, which is applied in the direction of sending objects, thin material processing, transportation and packaging, etc., which can solve the problems of reducing work efficiency, belt knotting, and more labor, so as to improve utilization rate, not easy to cut continuously, The effect of increasing the winding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with accompanying drawing:

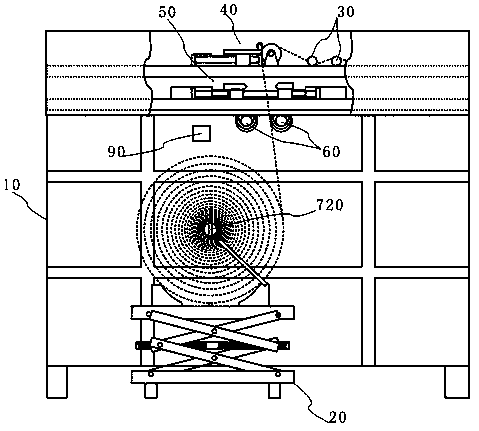

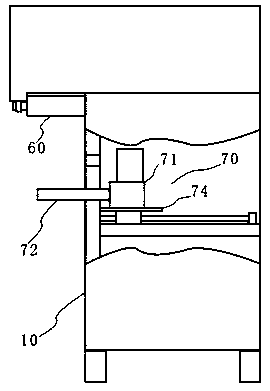

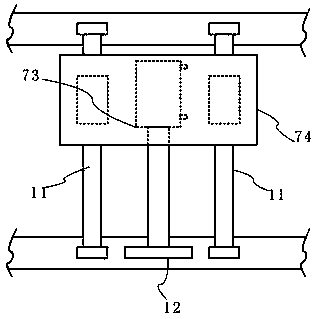

[0041] like Figure 1-10 As shown, the present embodiment provides an automatic counting and coiling machine, including a frame 10, a tray lifting platform 20, a tape guide roller group 30, a winding mechanism 70, a fuse mechanism 50, a limit assembly 60, a traction mechanism 40 and a For the electronic control system that controls the opening and closing of the winding mechanism 70, the fuse mechanism 50 and the traction mechanism 40, the guide roller group 30, the traction mechanism 40, the fuse mechanism 50 and the limit assembly 60 are sequentially arranged on the frame along the running direction of the ribbon 10, the winding mechanism 70 is arranged at the bottom of the frame 10 and the center of its winding station is on either side of the fusing station center of the fusing mechanism 50, and the limit assembly 60 is located at the front of the fusing station. There...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com