Feed slot cleaning equipment

A technology for cleaning equipment and feed troughs, which is applied in the directions of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below by means of specific embodiments:

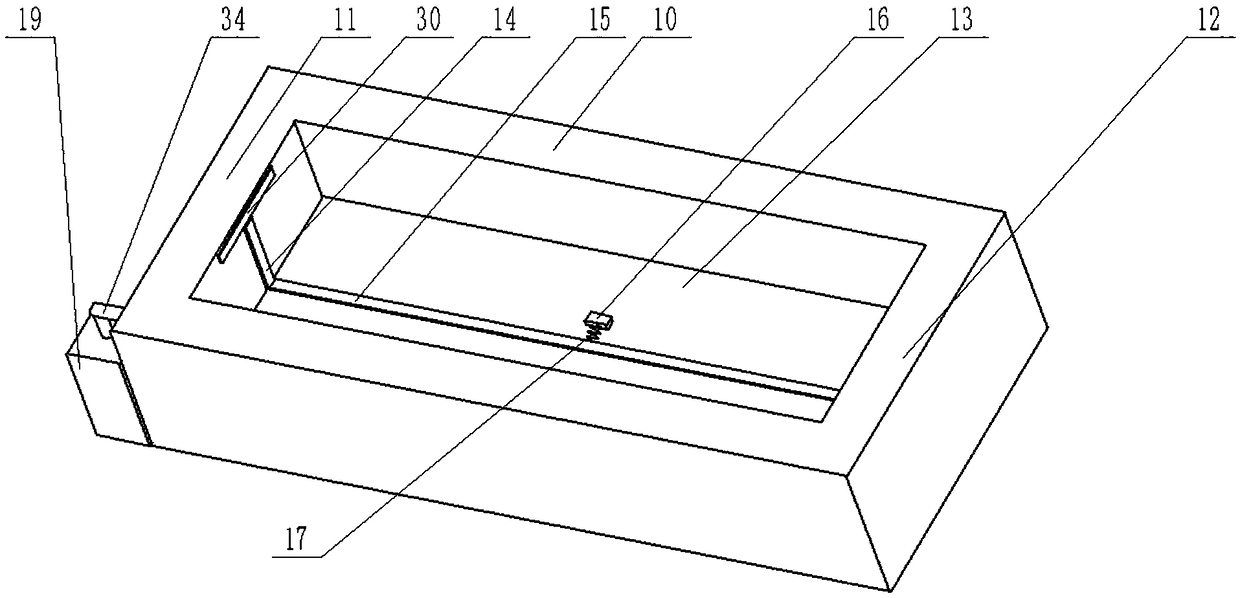

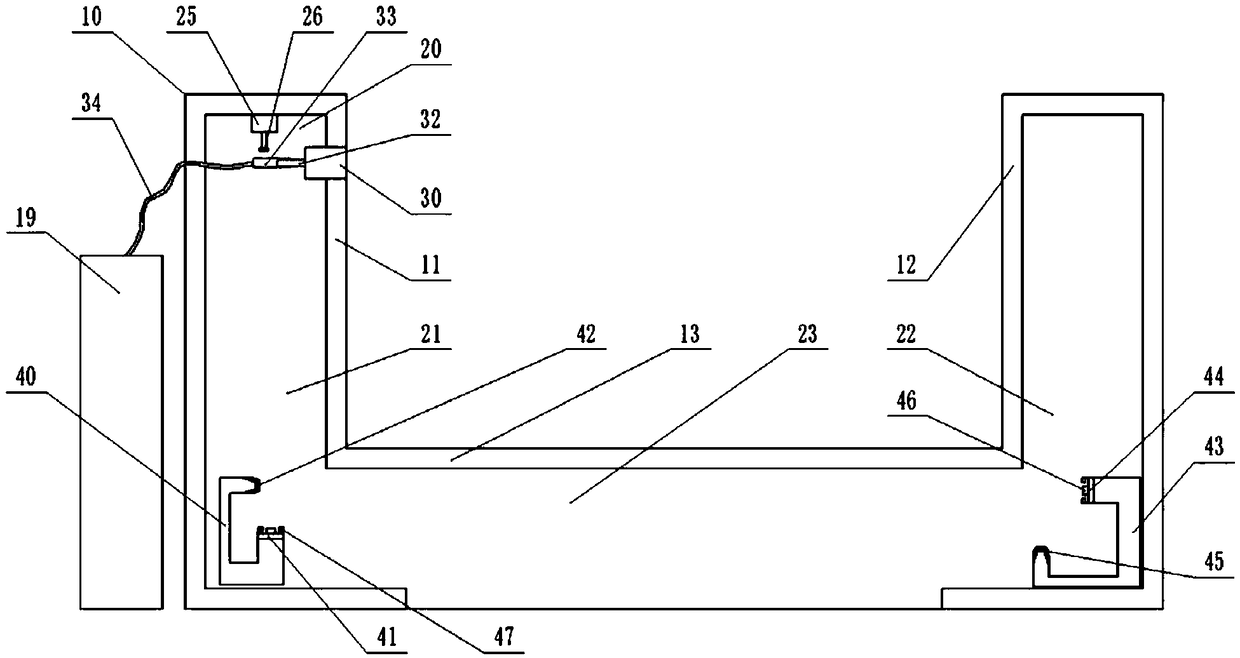

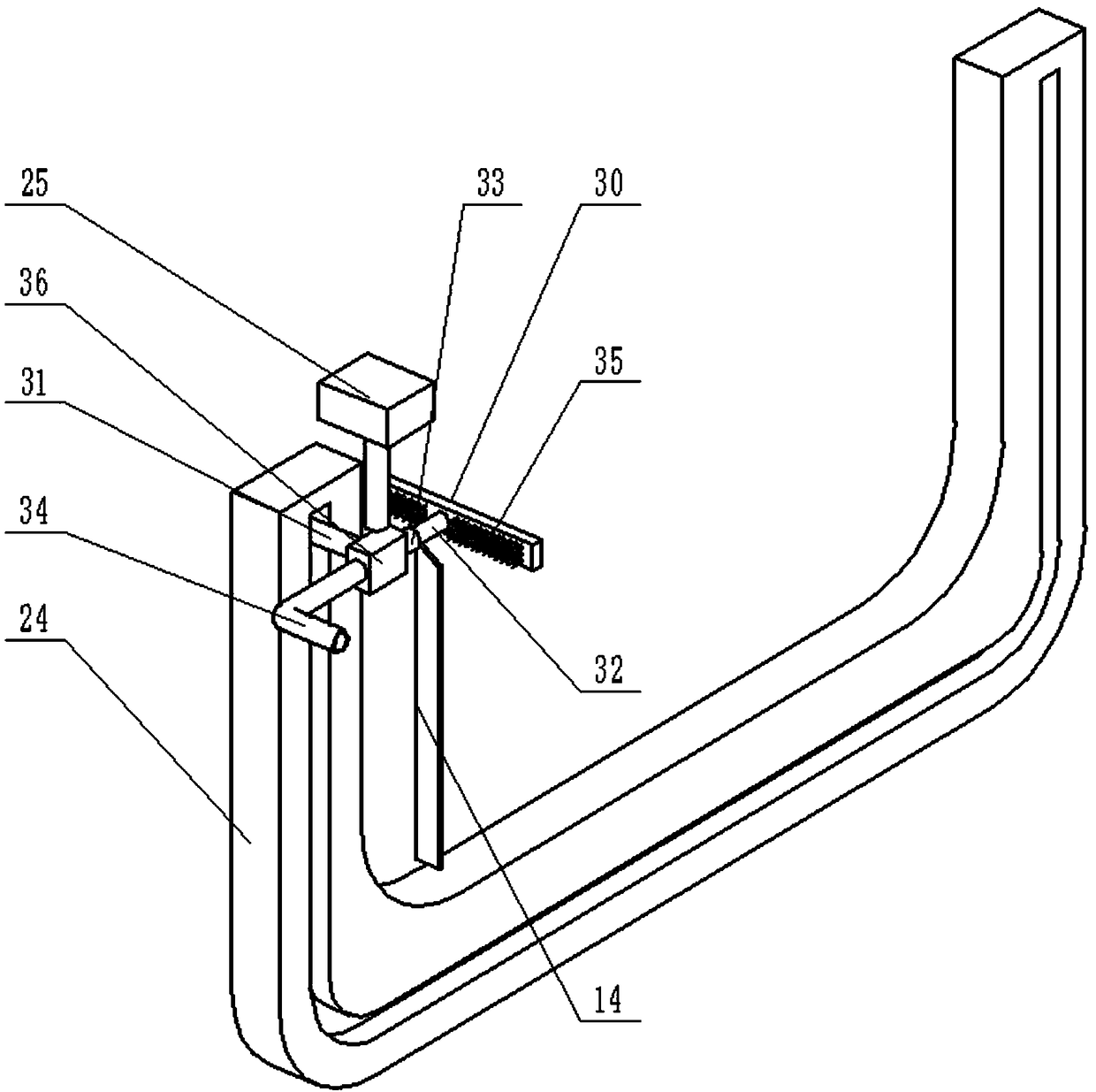

[0021] The reference numerals in the drawings of the description include: feed trough 10, first side plate 11, second side plate 12, bottom plate 13, first baffle plate 14, second baffle plate 15, spring plate 16, spring 17, discharge trough 18. Water storage tank 19, cavity 20, first side wall 21, second side wall 22, bottom wall 23, guide rail 24, cylinder 25, first magnet 26, brush block 30, slider 31, water inlet pipe 32, communication Tube 33, flexible tube 34, bristles 35, square tube 36, first piston tube 40, first piston 41, first telescopic tube 42, second piston tube 43, second piston 44, second telescopic tube 45, second Magnet 46, limit block 47.

[0022] like figure 1 As shown, the feed tank 10 cleaning equipment of the present embodiment includes a feed tank 10 and a water storage tank 19, the water storage tank 19 is provided with a water pump, and the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com