Sorting system, sorting platform and sorting unit thereof

A sorting system and platform technology, applied in sorting and other directions, can solve the problems of waste of design, production and construction costs, increase the height and thickness of the main beam of the steel platform, and reduce the efficiency of sorting and handling, and achieve the overall operation. The effect of improved efficiency, improved handling efficiency, improved handling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Embodiment 1 - the sorting unit of the parcel sorting platform

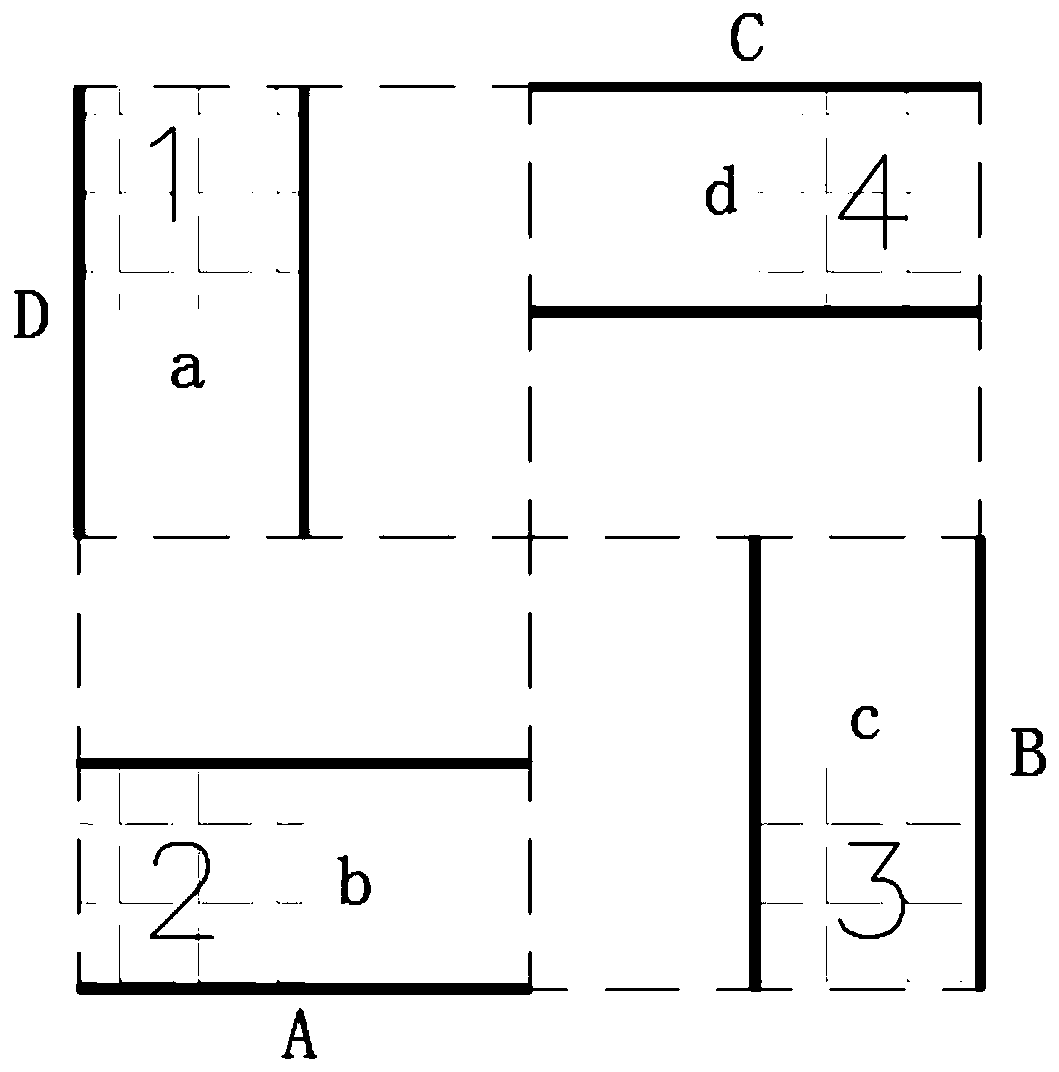

[0052] image 3 It is a schematic diagram showing the layout relationship of the partitions, slides, and cargo containers of the sorting platform according to the embodiment of the present invention, image 3 For top view. Among them, the part filled with "well" grid indicates the partition, the thick solid line indicates the chute, and the dotted line indicates the container. In this embodiment, 4 compartments are used as a compartment group, and 4 chutes and 4 cargo containers are correspondingly arranged below the 4 compartments.

[0053] refer to image 3 , the partition 1, the partition 2, the partition 3 and the partition 4 are a group of partitions, and the 4 partitions are arranged at intervals. The 4 partitions define a square outline (the dotted line area in the figure), and the 4 partitions are respectively located on the 4 corners of the square.

[0054] Below each compartment, there is ...

Embodiment 2

[0058] Example 2 - the sorting unit of the parcel sorting platform

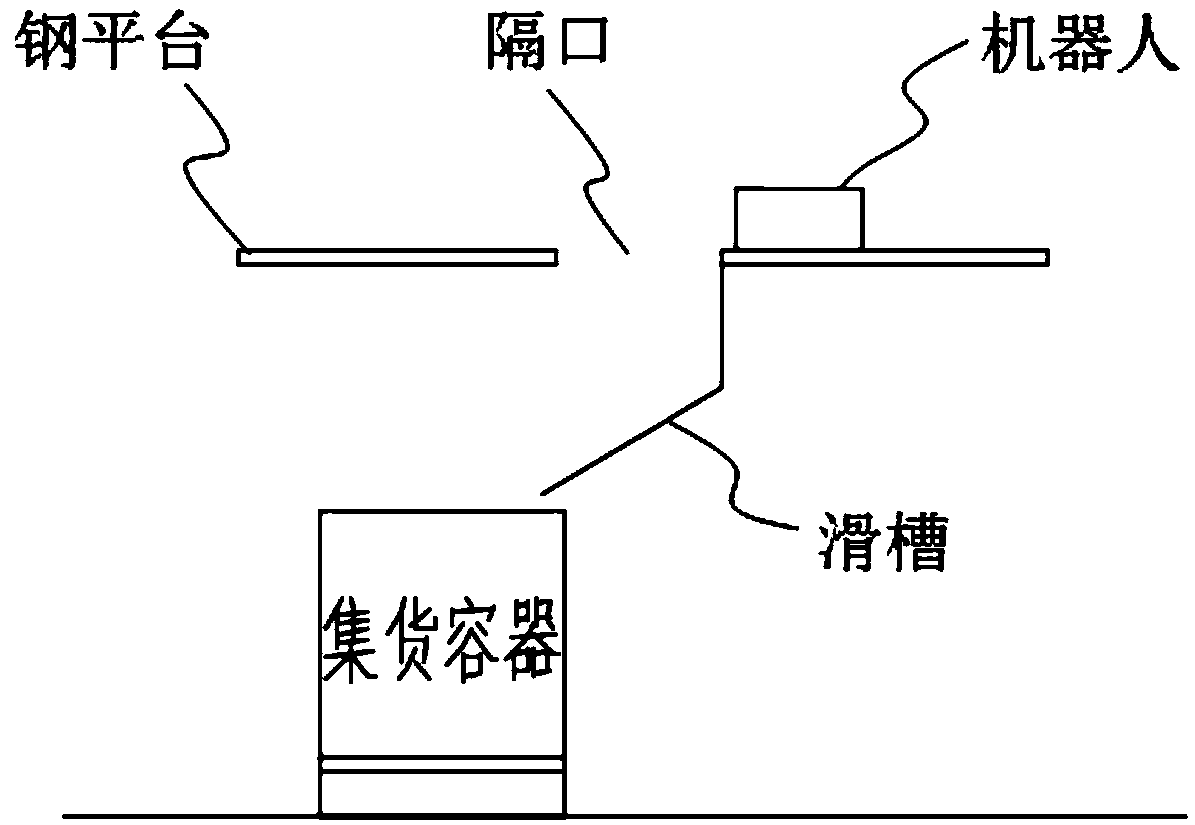

[0059] Figure 4 It is a schematic diagram showing the layout relationship of the partitions, slides, and cargo containers of the sorting platform according to the embodiment of the present invention, Figure 4 is a stereogram. In this embodiment, 4 compartments are used as a compartment group, and 4 chutes and 4 cargo containers are correspondingly arranged below the 4 compartments. 4 compartments, 4 chutes and 4 collecting containers form a circulation.

[0060] The difference between this embodiment and Embodiment 1 is that the four cargo containers are placed loosely instead of closely arranged. The so-called loose placement means that there is a certain gap between the adjacent collection containers in this group, but, compared to the distance between a certain collection container in this group and a certain collection container in other groups, the gap The width of the container is very small, so...

Embodiment 3

[0063] Example 3 - Parcel Sorting Platform

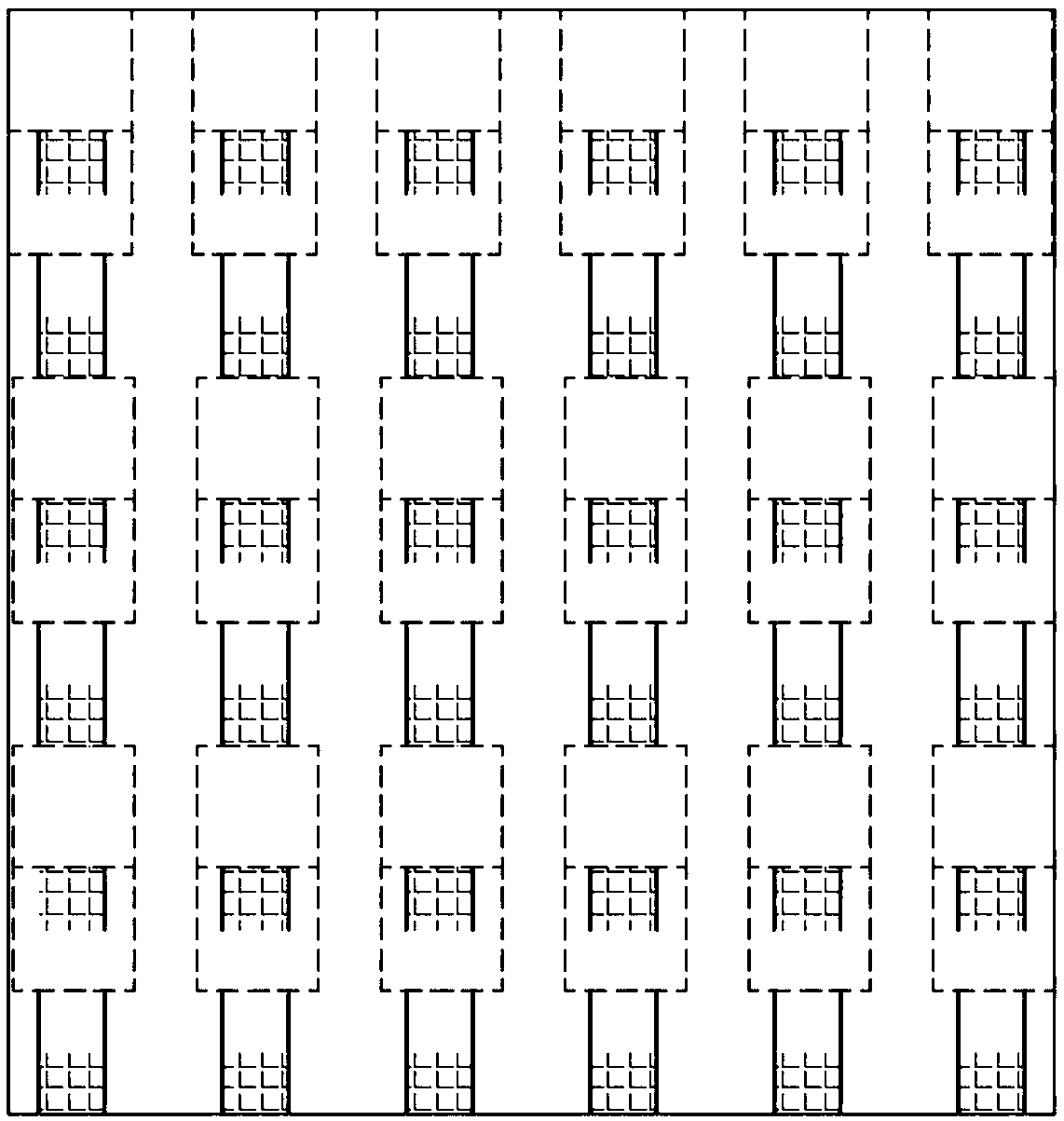

[0064] Figure 5 A schematic structural diagram of a sorting platform according to an embodiment of the present invention is shown. Image 6 It is a schematic diagram of the parcel sorting platform formed according to the traditional layout. Figure 5 with Image 6 For top view. The parcel sorting platform may include a steel platform and supporting columns for supporting the steel platform, and the partitions are arranged on the steel platform. Figure 5 with Image 6 There are the same number of openings on the steel platform, all of which are 36 openings. Image 6 The 36 compartments are distributed on the steel platform in a 6×6 arrangement.

[0065] refer to Figure 5 , divide the 36 compartments into 9 compartment groups, each group includes 4 compartments, and 4 chutes and 4 collection containers are correspondingly arranged below. The arrangement of the partitions, chutes and cargo containers in each partition grou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com