Process and device for preparing iron ore concentrate through mixture of aluminum oxide red mud tailings and copper tailings

A technology for copper tailings and mixed materials, applied in chemical instruments and methods, solid separation, wet separation, etc., can solve the problems of high production cost, low recovery rate, complex process flow, etc., and achieve lower production cost and high yield. , the effect of reducing the amount of efflux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

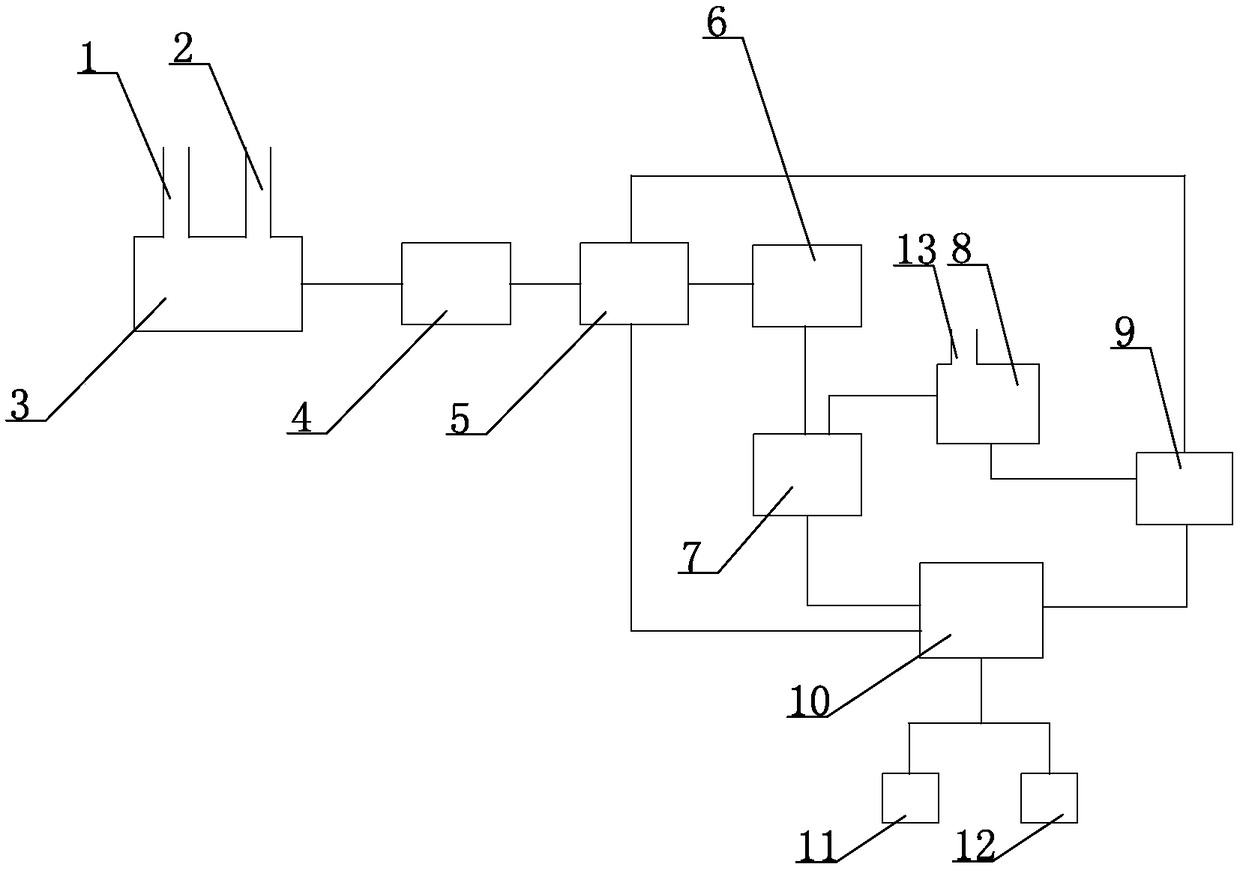

Image

Examples

Embodiment 1

[0037] A process for preparing iron ore concentrate from alumina red mud tailings and copper tailings mixture, the steps are as follows:

[0038] (1) Carry out sand treatment to the low-iron red mud tailings (TFe 8%), so that the moisture content is less than 18%, the viscosity is reduced, and the structure is loose; the red mud tailings obtained from the treatment are placed with the copper tailings according to The weight ratio is 1:1.8, and the material is sent to the mixing equipment for stirring and mixing. After the stirring is even, it is transported to the first storage yard by a belt for 36 hours, and then enters the second storage yard as a raw material after being turned over;

[0039](2) Utilize the slurry obtained by magnetic separation in step (4) and the filtrate obtained by the vertical disc filter to dilute the material obtained in step (1) in the washing liquid tank, and the solid content reaches 220g / l, and then the mixture slurry Sieve through a cylindrical...

Embodiment 2

[0049] A process for preparing iron ore concentrate from alumina red mud tailings and copper tailings mixture, the steps are as follows:

[0050] (1) Carry out sand treatment to the low-iron red mud tailings (TFe 12%), so that the moisture content is less than 20%, the viscosity is reduced, and the structure is loose; the red mud tailings obtained from the treatment are placed with the copper tailings according to the The weight ratio is 1:3, and the material is sent to the mixing equipment for stirring and mixing. After the stirring is even, it is transported to the first storage yard by a belt for 48 hours, and then enters the second storage yard as a raw material after being turned over;

[0051] (2) Utilize the slurry obtained by magnetic separation in step (4) and the filtrate obtained by the vertical disc filter to dilute the material obtained in step (1) in the washing liquid tank, and the solid content reaches 240g / l, and then the mixture slurry Sieve through a cylindr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com