Intelligent maintenance method and system for tobacco cutter based on automatic optical inspection technology

An automatic optical detection and shredding machine technology, which is applied in food science, computer parts, character and pattern recognition, etc., to achieve efficient and intelligent maintenance strategies, improve accuracy and adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

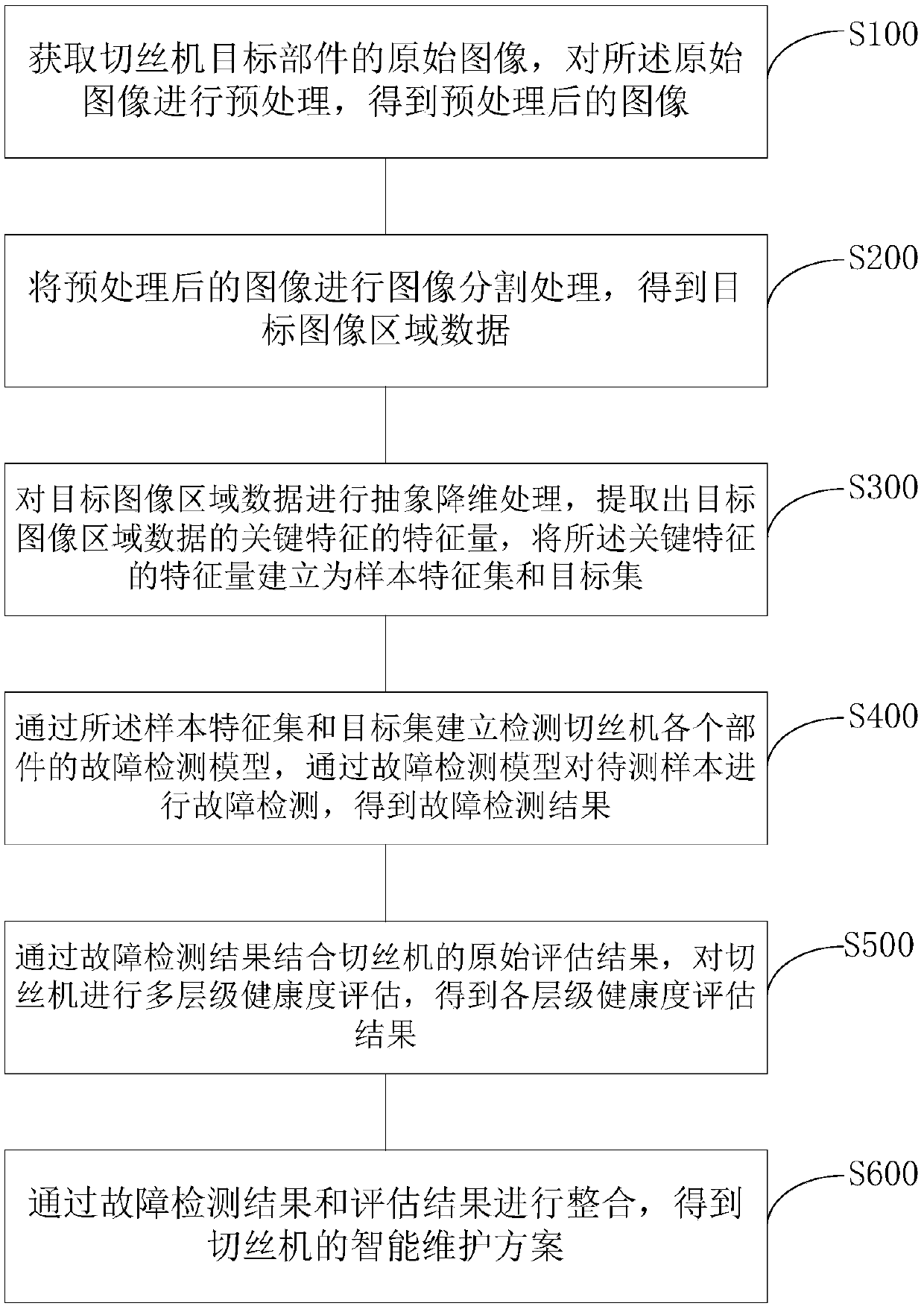

[0064] An intelligent maintenance method for shredding machine based on automatic optical detection technology, such as figure 1 shown, including the following steps:

[0065] S100. Obtain an original image of the target component of the shredding machine, perform preprocessing on the original image, and obtain a preprocessed image;

[0066] S200. Perform image segmentation processing on the preprocessed image to obtain target image area data;

[0067] S300. Perform abstract dimensionality reduction processing on the target image area data, extract the feature quantities of the key features of the target image area data, and establish the feature quantities of the key features as a sample feature set and a target set;

[0068] S400. Establish a fault detection model for detecting each component of the shredder through the sample feature set and target set, and perform fault detection on the sample to be tested through the fault detection model to obtain a fault detection resu...

Embodiment 2

[0103] An intelligent maintenance system for wire cutters based on automatic optical detection technology, such as figure 2 As shown, it includes an image acquisition module 100, an image preprocessing module 200, an image segmentation module 300, a feature extraction module 400, a fault detection module 500, a health assessment module 600, an intelligent maintenance module 700, an update module 800 and a self-learning module 900;

[0104] The image acquisition module 100 is used to acquire the original image of the target part of the shredding machine;

[0105] The image preprocessing module 200 is configured to preprocess the original image to obtain a preprocessed image;

[0106] The image segmentation module 300 is configured to perform image segmentation processing on the preprocessed image to obtain target image area data;

[0107] The feature extraction module 400 is used to perform abstract dimension reduction processing on the target image area data, extract the fea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com