Biomass particle temperature-increasing and freeze-proofing system for heliogreenhouse

A technology of biomass particles and antifreeze system, which is applied in the field of solar greenhouse auxiliary facilities, can solve problems such as inability to solve problems stably and efficiently, and achieve significant technological advancement, reduce heat loss, and improve utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

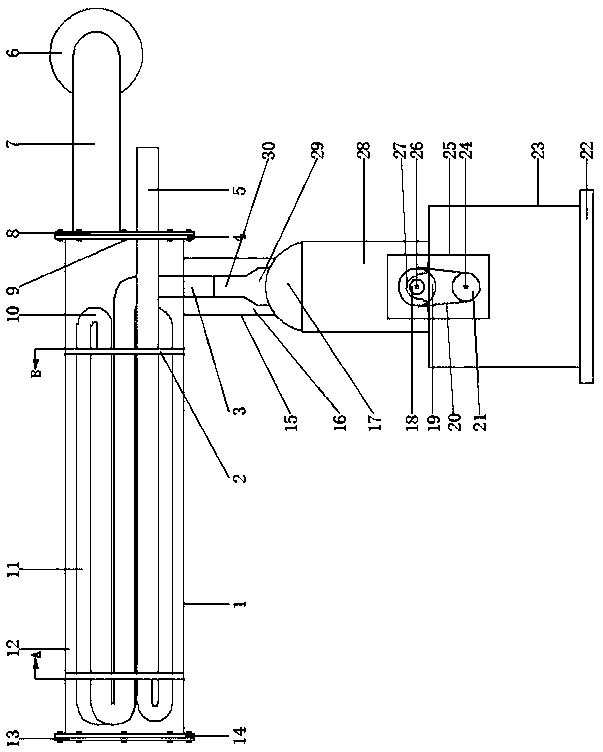

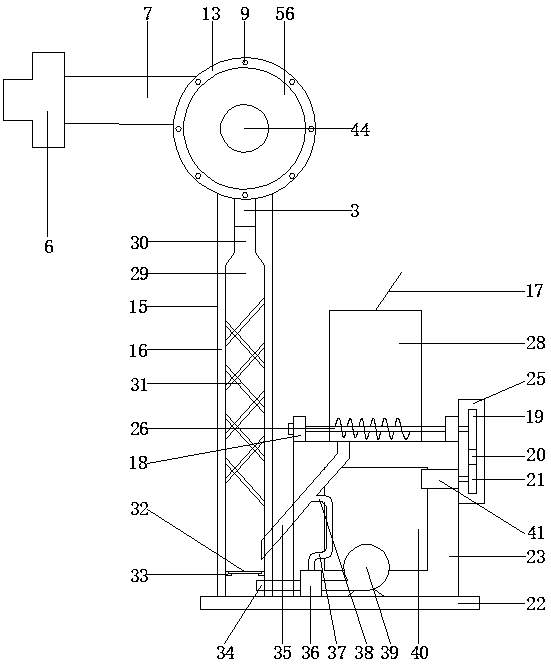

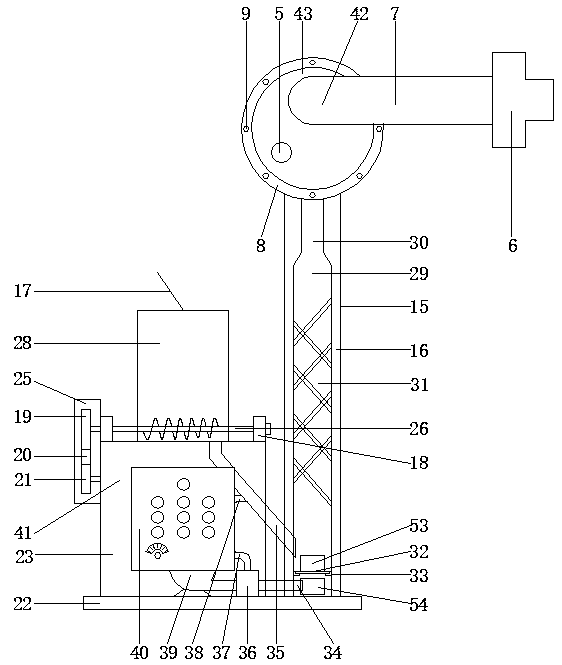

[0042] The present invention will be further described below in conjunction with the description of the drawings.

[0043] Such as figure 1 , 2 , 3, 4, 5, 6, 7, 8, a solar greenhouse biomass pellet heating and antifreeze system, including a fuel feeder, a burner, a heat exchange device and a base 22, a fuel feeder, a combustion engine The engine is fixedly connected to the base 22; the fuel feeder includes a body 23, a fuel bin 28 and a feeding pipe 35. The body 23 is fixed on the upper surface of the base 22, the fuel bin 28 is fixedly connected to the top of the body 23 and the bottom of the fuel bin 28 The feed pipe 35 is fixedly connected, the bottom of the fuel bin 35 is provided with an auger 26, both ends of the auger 26 are fixedly connected to the body 23 through a fixed bearing 18, and one end of the auger 26 is fixedly connected with a driven sprocket 19, and the body 23 is a A motor 41 is built on one side, a control box 40 is embedded on the other side, and a blower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com