Core wire automatic half stripping and managing mechanism

An automatic and wire management technology, applied in the direction of line/collector components, electrical components, circuits, etc., can solve the problems of slow manual operation, high defective rate, copper wire damage, etc., and achieve low production cost, high production efficiency, The effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to describe the technical content and structural features of the present invention in detail, further description will be given below in conjunction with the implementation and accompanying drawings.

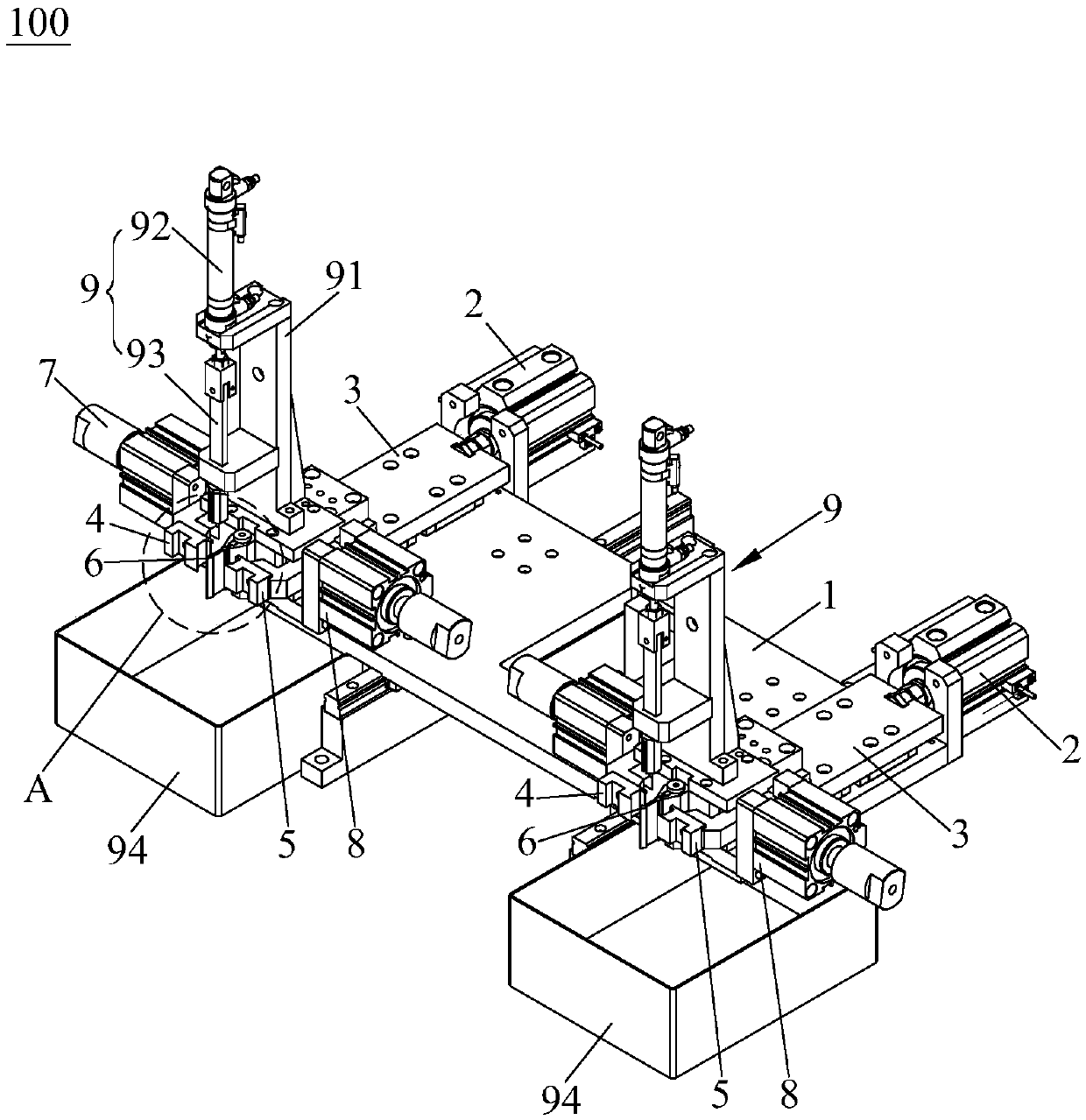

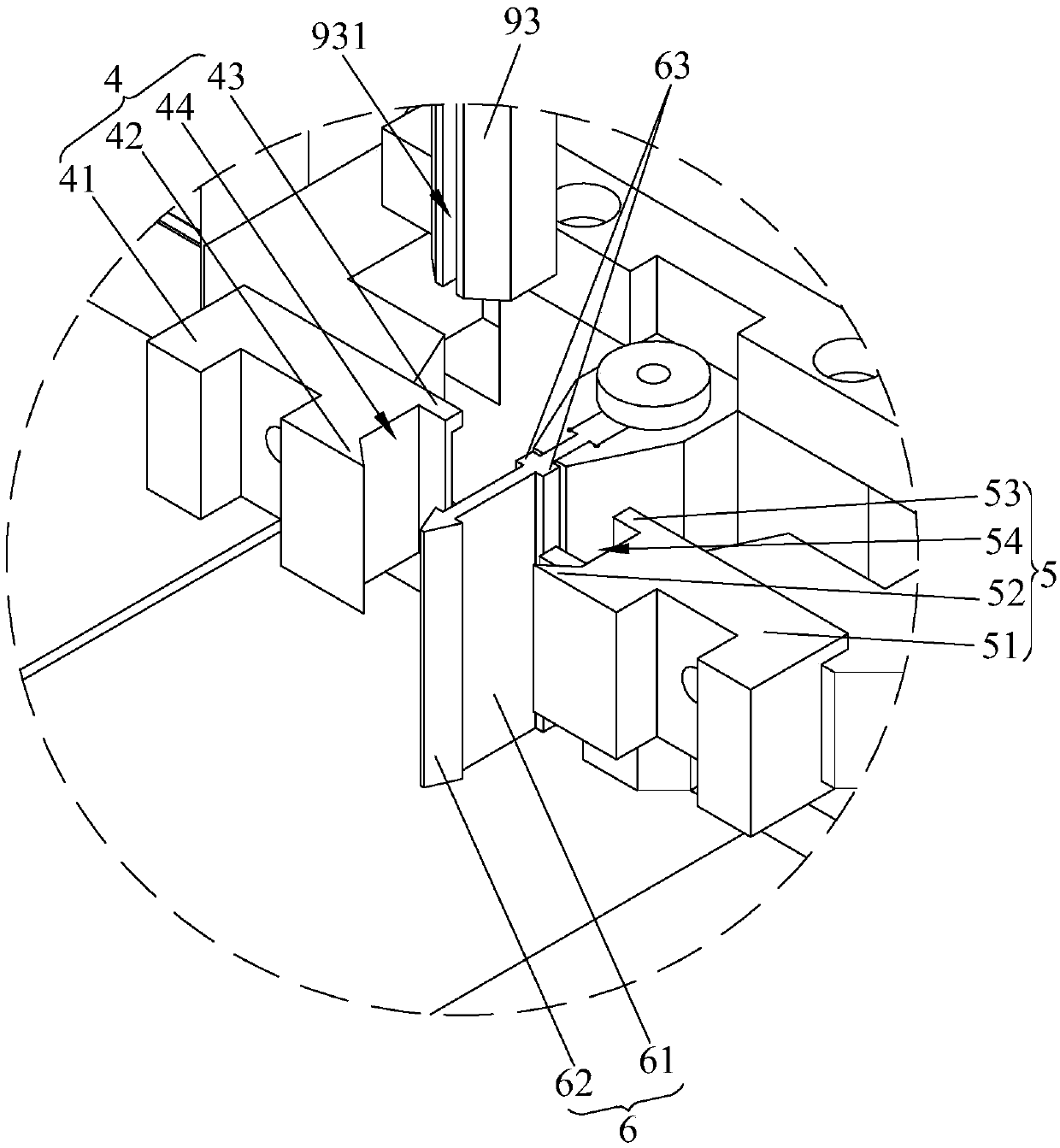

[0018] see figure 1 and figure 2 , the core wire automatic half-stripping and management mechanism 100 of the present invention can be applied to cutting and peeling the core wire on the assembly line, but not limited thereto; the core wire automatic half-stripping and management mechanism 100 includes a base 1, a peeling drive Device 2, pulling plate 3, first thread cutting knife 4, second thread cutting knife 5, first thread cutting driving device 7, second thread cutting driving device 8 and thread slag cleaning device 9, peeling driving device 2 is set on the base 1, the pull plate 3 is slidably arranged on the base 1, the output end of the peeling drive device 2 is connected with the pull plate 3 and can drive the pull plate 3 to slide, the first tangent d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com