EMC Cable Glands

A compatible, cable lock technology, applied in conductive connection, clamping/spring connection, connection, etc., can solve the problems that copper terminals cannot be quickly passed through, cannot be quickly grounded, and cable shielding installation is troublesome, saving man-hours , easy to plug, good shielding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

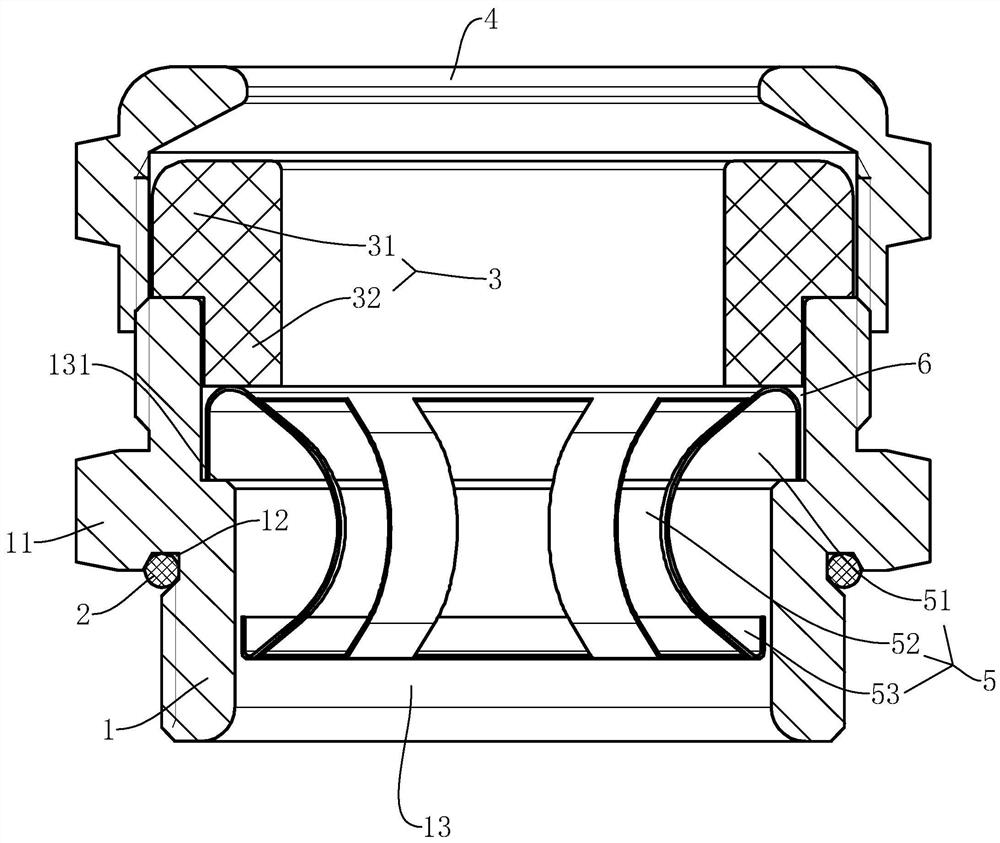

[0020] pass Figure 1 to Figure 2 The electromagnetic compatible cable locking joint of the present invention will be further described.

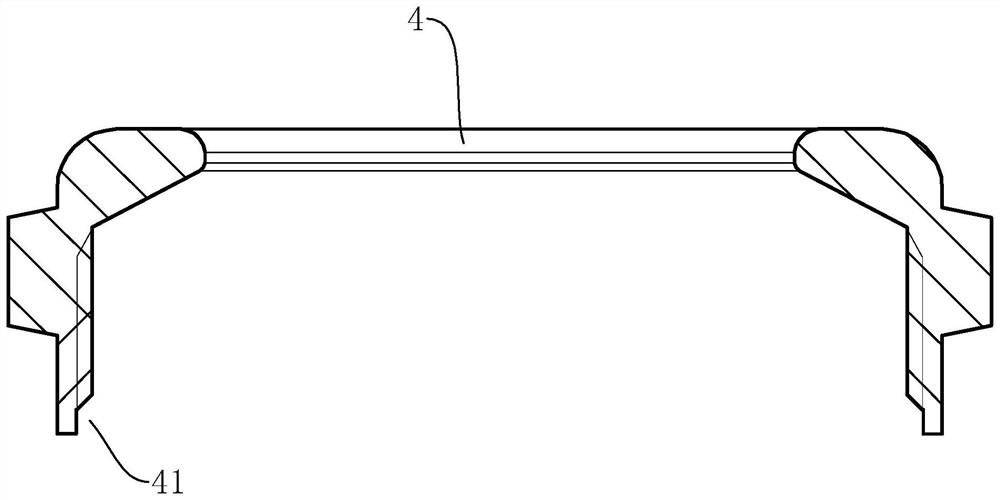

[0021] An electromagnetic compatible cable locking joint, comprising a joint body 1 , a joint cap 4 , a sealing ring 3 and a shield 5 .

[0022] The joint main body 1 has a central hole 13, which is arranged in a tubular shape. There is an inner step 131 in the central hole. The sealing ring 3 is connected to the end of the joint main body 1, and a positioning is formed between the sealing ring 3 and the inner step. Slot 6. That is, the outer surface of the sealing ring 3 is stepped, and is divided into an upper section 32 and a lower section 31, and the upper section 32 is screwed into the central hole, so a positioning groove 6 is formed between the inner step and the end wall of the upper section 32 , the end wall of the lower section 31 abuts against the end wall of the joint main body 1 . The joint cap 4 is threadedly connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com