Anti-collision device for wharf

A technology for anti-collision devices and docks, applied in shipping equipment, climate change adaptation, etc., can solve problems such as poor buffering effect, damage to docks, easy damage of anti-collision devices, etc., and achieve improved anti-collision effects, improved service life, and buffering effects Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

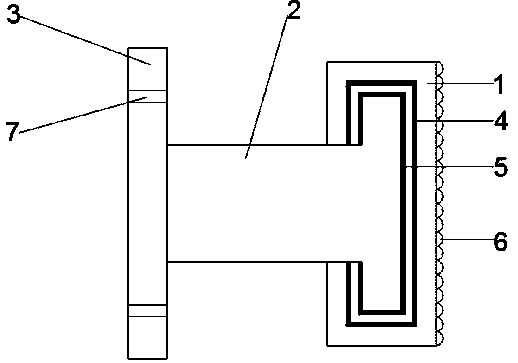

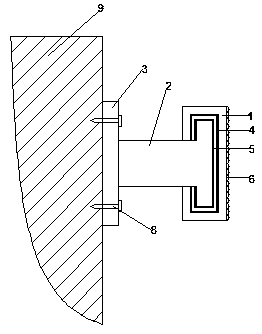

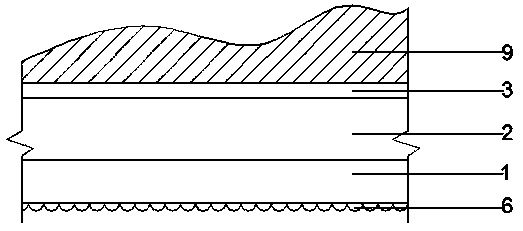

[0016] Example: such as Figure 1-3 Shown, a kind of wharf anti-collision device comprises buffer slide block 1, anti-collision column 2, installation substrate 3, magnet bar one 4, magnet bar two 5, buffer layer 6, mounting hole 7 and expansion bolt 8, and described buffer The longitudinal section shape of the slider 1 is C-shaped, the buffer layer 6 is set on the anti-collision contact surface of the buffer slider 1, and the magnet bar-4 is arranged on the inner surface of the buffer slider 1; the section shape of the buffer column 2 is T-shaped, and the section The outer surface of the larger end is provided with a magnet strip 2 5, the buffer slider 1 is sleeved on the larger side of the buffer column 2, and the smaller end of the buffer column 2 is fixedly connected with the installation substrate 3, and is set by the expansion bolt 8. On the side wall of the pier 9; the magnet strip one 4 and the magnet strip two 5 are of the same sex, and because the same sex repels eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com