Total prefabricated pier, cushion cap and beam body prefabricated construction movable cantilever type bridge girder erection machine

A bridge erecting machine, cantilever type technology, applied in the field of mobile cantilever bridge erecting machine, to reduce labor intensity, improve industrial construction technology, and improve construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

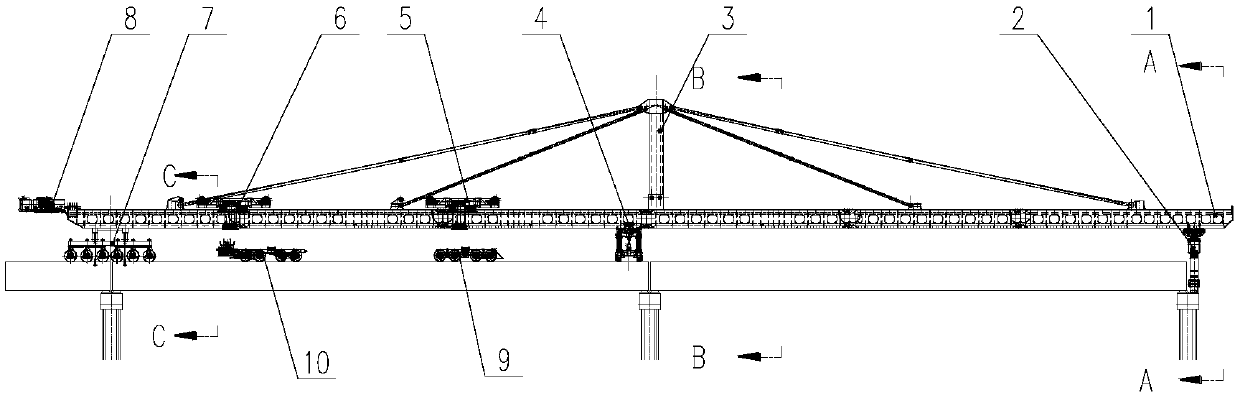

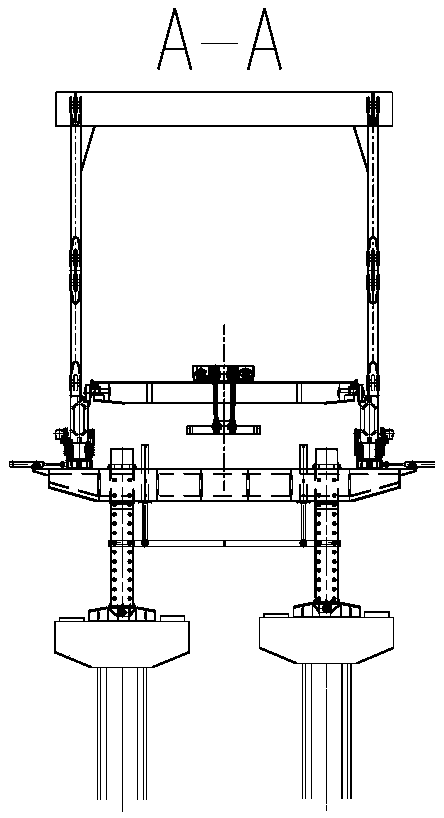

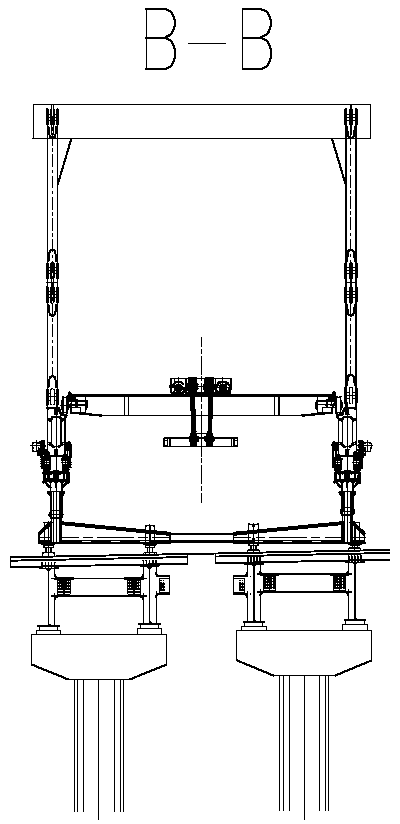

[0052] see Figure 1 to Figure 6 , shows the mobile cantilever type bridge erecting machine for fully prefabricated bridge piers, caps and girder assembly construction of the present invention.

[0053] The mobile cantilever bridge erecting machine of the fully prefabricated bridge pier, cap and girder body assembly construction may include main girder 1, front outrigger 2, tie rod system 3, middle outrigger 4, front lifting trolley 5, rear lifting Dolly 6, rear supporting leg 7, power system 8, also can be provided with the preceding beam transporting vehicle 9 and the rear transporting beam transporting vehicle 10 as the supporting transportation equipment of bridge erecting machine.

[0054] see figure 1As shown, the front end of the main beam 1 is supported by the front leg 2, the rear end is supported by the rear leg 7, and the middle part is supported by the middle leg 4. The tie rod system 3, the front lifting trolley 5, the rear The lifting trolley 6 and the power sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com