Construction process for pier top section of hollow thin-walled high pier column

A hollow, thin-walled, construction technology that is applied to bridge parts, erection/assembly bridges, bridges, etc., can solve problems such as low construction efficiency and high construction difficulty, and achieve tight construction schedules, fast construction speed, and easy control and adjustment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

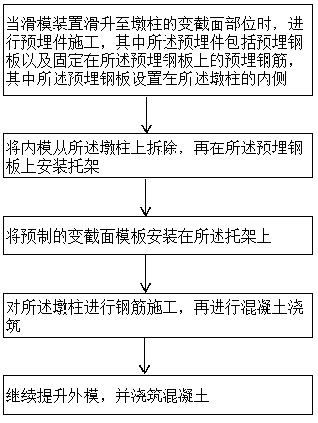

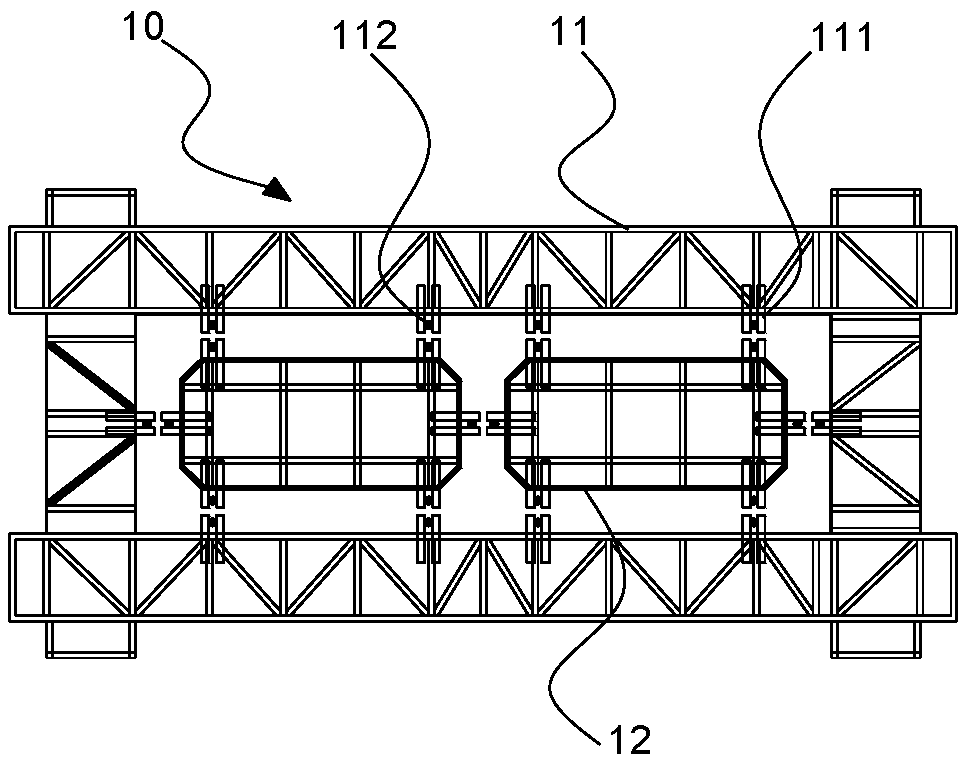

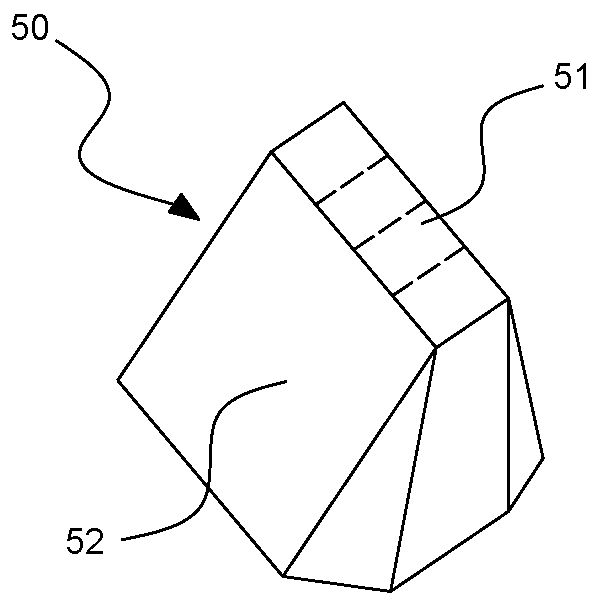

[0026] Such as Figure 1 to Figure 5 As shown, this embodiment provides a construction process for the top section of a hollow thin-walled high pier column, using a sliding form device 10 to construct the pier column 20, wherein the sliding form device 10 includes an outer form 11 and a The inner mold 12 in the mold 11 includes the following steps: Step S1: When the sliding form device 10 slides up to the variable cross-section position of the pier column 20, the construction of the embedded part 30 is carried out, wherein the embedded part 30 It includes a pre-embedded steel plate 31 and a pre-embedded steel bar 32 fixed on the pre-embedded steel plate 31, wherein the pre-embedded steel plate 31 is arranged on the inner side of the pier column 20; Remove the pier column 20, and then install the bracket 40 on the pre-embedded steel plate 31; Step S3: Install the prefabricated variable-section formwork 50 on the bracket 40; Step S4: Reinforce the pier column 20 Construction, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com